Additive manufacturing, also known as 3D printing, involves building an object layer by layer using a computer-controlled process. Detecting defects in real time during the manufacturing process can help to improve the quality and reliability of the final product. This can be done by using sensors and cameras to monitor the printing process and detect any issues that arise. Additionally, software algorithms can be used to analyze the data from the sensors and cameras to identify potential defects and alert the operator to take corrective action. Overall, detecting defects in real time can help to improve the efficiency of the manufacturing process and increase the yield of high-quality products.

Researchers can now detect keyhole pores, one of the most difficult defects in additive manufacturing, with incredible accuracy. Tao Sun, associate professor of materials science and engineering at the University of Virginia, led a research team that made new discoveries that could help expand additive manufacturing in aerospace and other industries that rely on strong metal parts.

Their peer-reviewed paper, “Machine learning aided real-time detection of keyhole pore generation in laser powder bed fusion,” was published in Science Magazine. It addresses the problem of detecting keyhole pores, which are one of the major flaws in a common additive manufacturing technique known as laser powder bed fusion, or LPBF.

Our findings not only advance additive manufacturing research, but they can also serve to practically expand the commercial use of LPBF for metal part manufacturing.

Rollett

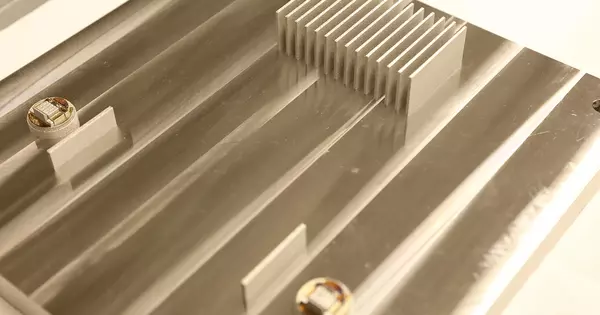

LPBF, which was introduced in the 1990s, uses metal powder and lasers to 3-D print metal parts. However, porosity defects continue to be a problem in fatigue-sensitive applications such as aircraft wings. Some porosity is associated with keyholes, which are deep and narrow vapor depressions.

The size and shape of the keyhole are determined by laser power and scanning velocity, as well as the materials’ ability to absorb laser energy. If the keyhole walls are stable, the surrounding material’s laser absorption improves and laser manufacturing efficiency improves. If the walls become shaky or collapse, the material solidifies around the keyhole, trapping the air pocket inside the newly formed layer of material. This makes the material more brittle and prone to cracking when subjected to environmental stress.

Sun and his colleagues, which included Carnegie Mellon University materials science and engineering professor Anthony Rollett and University of Wisconsin-Madison mechanical engineering professor Lianyi Chen, developed a method for detecting the precise moment when a keyhole pore forms during the printing process.

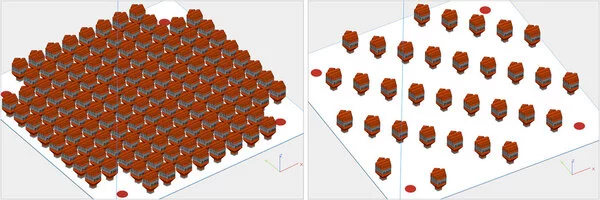

“Our approach can capture the unique thermal signature associated with keyhole pore generation with sub-millisecond temporal resolution and 100% prediction rate by integrating operando synchrotron x-ray imaging, near-infrared imaging, and machine learning,” Sun said.

In developing their real-time keyhole detection method, the researchers also advanced the way a state-of-the-art tool — operando synchrotron x-ray imaging — can be used. Utilizing machine learning, they additionally discovered two modes of keyhole oscillation.

“Our findings not only advance additive manufacturing research, but they can also serve to practically expand the commercial use of LPBF for metal part manufacturing,” Rollett said. Rollet is also a co-director of CMU’s NextManufacturing Center.

“Porosity in metal parts continues to be a significant barrier to wider adoption of the LPBF technique in some industries. Because it occurs stochastically beneath the surface, keyhole porosity is the most difficult defect type to detect in real time using lab-scale sensors “Sun stated. “Our approach provides a viable solution for high-fidelity, high-resolution detection of keyhole pore generation in many additive manufacturing scenarios.”