The up-and-coming age of 2D semiconductor materials could do without what it sees when it thoroughly searches in the mirror. Current orchestrating ways to make single-layer nanosheets of semiconducting material for molecularly meager hardware create a particular “reflect twin” imperfection when the material is kept on single-gem substrates like sapphire. The blended nanosheet contains grain limits that go about as a mirror, with the game plan of particles on each side coordinated in reflected resistance to each other.

This is an issue, as indicated by specialists from Penn State’s Two-Layer Gem Consortium-Materials Development Stage (2DCC-MIP) and their colleagues. Electrons disperse when they hit the limit, diminishing the presentation of gadgets like semiconductors. This is a bottleneck, the scientists said, for the progress of cutting-edge gadgets for applications like the Web of Things and man-made reasoning. However, presently, the examination group might have thought of an answer to correct this imperfection. They have published their work in Nature Nanotechnology.

This study could essentially affect semiconductor research by empowering different analysts to decrease twin deformities, as indicated by lead creator Joan Redwing, overseer of 2DCC-MIP, particularly as the field has expanded consideration and subsidizing from the CHIPS and Science Act endorsed a year ago. The regulation’s approval expanded subsidizing and different assets to help America’s endeavors to coast the creation and improvement of semiconductor innovation.

“We used sapphire wafers as a template to align the tungsten diselenide crystals as they deposit by MOCVD on the wafer surface in order to produce single-layer sheets with a high degree of crystalline perfection,”

Redwing, who is also a distinguished professor of materials science and engineering.

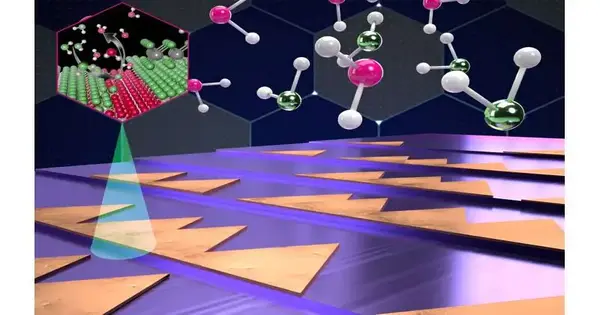

A solitary-layer sheet of tungsten diselenide—just three molecules thick—would make for a profoundly powerful, molecularly meager semiconductor to control the electrical flow stream, as indicated by Redwing. To make the nanosheet, the scientists utilize metal natural compound fume statement (MOCVD), a semiconductor fabricating innovation that is utilized to store super meager, single precious stone layers onto a substrate, in this case a sapphire wafer.

While MOCVD is utilized in the union of different materials, the 2DCC-MIP specialists spearheaded its utilization for the amalgamation of 2D semiconductors, for example, tungsten diselenide, Redwing said. Tungsten diselenide has a place in a class of materials called change metal dichalcogenides that are three-particle thick, with the tungsten metal sandwiched between non-metal selenide molecules, that shows beneficial semiconducting properties for cutting-edge gadgets.

“To accomplish single-layer sheets with a serious level of translucent flawlessness, we involved sapphire wafers as a layout to adjust the tungsten diselenide gems as they are stored by MOCVD on the wafer surface,” said Redwing, who is likewise a recognized teacher of materials science and design and of electrical design at Penn State. “Be that as it may, the tungsten diselenide precious stones can adjust in inverse headings on the sapphire substrate. As the oppositely arranged precious stones develop in size, they at last get together with each other on the sapphire surface to frame the mirror twin limit.”

To address this issue and get a large portion of the tungsten diselenide precious stones to line up with the sapphire gems, the scientists exploited “ventures” on the sapphire surface. The single sapphire precious stone that makes up the wafer is profoundly amazing in material science terms; nonetheless, it isn’t entirely level at the nuclear level. On a superficial level, there are steps that are a simple particle or two tall, with level regions between each step.

Here, Redwing said, the analysts found the associated source with the mirror imperfection.

The step on the sapphire precious stone surface is where the tungsten diselenide gems would in general join, but not always. The gem arrangement, when joined to the means, would in general be in each of the courses.

“On the off chance that the gems can be generally adjusted in a similar course, then reflect twin imperfections in the layer will be decreased or even dispensed with,” Redwing said.

The analysts found that by controlling the MOCVD cycle conditions, the greater part of the gems could be made to join the sapphire at the means. What’s more, during the tests, they made a reward revelation: In the event that the precious stones join at the highest point of the step, they adjust in one crystallographic bearing; assuming they join at the base, they adjust the other way.

“We observed that it was feasible to get most of the gems to connect at either the top or the base edge of the means,” Redwing said, crediting trial work performed by Haoyue Zhu, a postdoctoral researcher, and Tanushree Choudhury, an aide research teacher, in 2DCC-MIP. “This would give an approach to fundamentally diminishing the quantity of mirror-twin limits in the layers.”

Nadire Nayir, a postdoctoral researcher coached by Recognized College Teacher Adri van Duin, drove scientists in the 2DCC-MIP Hypothesis/Reproduction office to foster a hypothetical model of the nuclear construction of a sapphire surface to make sense of why the tungsten diselenide joined to the top or base edge of the means. That’s what they hypothesized: on the off chance that the outer layer of the sapphire was covered with selenium molecules, they would append to the base edge of the means; assuming the sapphire is just to some extent covered with the goal that the base edge of the step needs selenium iota, then the gems would join to the top.

To affirm this hypothesis, the Penn State 2DCC-MIP scientists worked with Krystal York, an alumni understudy in the exploration gathering of Steven Durbin, teacher of electrical and PC design at Western Michigan College. She added to the concentration as a feature of the 2DCC-MIP Inhabitant Researcher Guest Program. York figured out how to develop tungsten diselenide meager movies by means of MOCVD while involving 2DCC-MIP offices for her doctoral proposal research. Her investigations affirmed that the strategy worked.

“While completing these analyses, Krystal saw that the course of tungsten diselenide spaces on sapphire exchanged when she shifted the strain in the MOCVD reactor,” Redwing said. “This exploratory perception gave confirmation of the hypothetical model that was created to make sense of the connection area of tungsten diselenide precious stones on strides on the sapphire wafer.”

Wafer-scale tungsten diselenide tests on sapphire created utilizing this original MOCVD process are accessible to specialists beyond Penn State by means of the 2DCC-MIP client program.

“Applications, for example, computerized reasoning and the Web of Things, will require further execution upgrades as well as ways of diminishing the energy utilization of gadgets,” Redwing said. “Top-notch 2D semiconductors in view of tungsten diselenide and related materials are significant materials that will assume a part in cutting-edge hardware.”

More information: Haoyue Zhu et al, Step engineering for nucleation and domain orientation control in WSe2 epitaxy on c-plane sapphire, Nature Nanotechnology (2023). DOI: 10.1038/s41565-023-01456-6