CPU planners, materials researchers, scholars, and different researchers currently have an uncommon degree of admittance to the universe of nanoscale materials because of 3D perception programming that is associated straightforwardly with an electron magnifying lens, empowering scientists to see and control 3D representations of nanomaterials continuously.

The capabilities are remembered for another beta version of Tomviz, an open-source 3D information perception device used by a large number of scientists.The new form rethinks the perception cycle, making it conceivable to go from magnifying lens tests to 3D representations in minutes rather than days.

As well as creating results more rapidly, the new abilities empower scientists to see and control 3D perceptions during a continuous trial. That could decisively speed up research in fields like chips, electric vehicle batteries, lightweight materials and numerous others.

For instance, “It has been a longstanding dream of the semiconductor business, for instance, to have the option to do tomography in a day, and here we’ve sliced it to under 60 minutes,” said Robert Hovden, an associate professor of materials science and design at U-M and related creator of the paper, published in Nature Communications. “You can begin deciphering and doing science before you’re even finished with a test.”

“You never really know what you’re going to find when working with an imperceptible realm like nanomaterials until you start to see it. Therefore, it greatly affects the research process to be able to start interpreting and making changes while you’re still using the microscope.”

Robert Hovden, an assistant professor of materials science and engineering at U-M

Hovden makes sense of that the new programming pulls information straight from an electron magnifying lens as it’s made and shows results right away, a key change from past forms of tomviz. Before, scientists assembled information from the electron magnifying lens, which takes many two-layered projection pictures of a nanomaterial from a few unique points. Then, they returned the projections to the lab to decipher and set them up prior to taking care of them to Tomviz, which would require a few hours to create a 3D perception of an item. The whole cycle required four to seven days, and an issue with one stage of the interaction frequently implied the beginning once again.

The new form of Tomviz does all the translation and handling on the spot. Scientists get a shadowy yet helpful 3D render in a couple of moments, which slowly improves into a definite perception.

“While you’re working in an undetectable world like nanomaterials, you never truly understand what you will find until you begin seeing it,” Hovden said. “So the capacity to start deciphering and making changes while you’re still on the magnifying lens has an immense effect on the examination cycle.”

The sheer speed of the new cycle could also be beneficial in industry — semiconductor chip designers, for example, could use tomography to run tests on new chip designs, looking for flaws in three-layered nanoscale hardware that is too small to see.Before, the tomography cycle was excessively delayed to run the many tests expected in a business office, yet Hovden accepts that tomviz could change that.

Hovden stresses that Tomviz can be run on a standard consumer-grade PC. It can be associated with fresher or more seasoned models of electron magnifying lenses. Also, on the grounds that it’s open-source, the actual product is available to everybody.

“Open-source programming is an incredible device for enabling science worldwide. “We made the association between Tomviz and the magnifying lens skeptic to the magnifying lens maker,” Hovden said. Furthermore, on the grounds that the product just glances at the information from the magnifying lens, it doesn’t mind whether that magnifying lens is the most recent model at U-M or a twenty-year-old machine.

To foster the new capacities, the U-M group drew on its longstanding organization with programming designer Kitware and, furthermore, welcomed in a group of researchers who work at the convergence of information science, materials science, and microscopy.

Toward the beginning of the cycle, Hovden worked with Marcus Hanwell of Kitware and Brookhaven National Laboratory to sharpen the possibility of a form of tomviz that would empower ongoing perception and trial and error. Then, Hovden and Kitware’s designers teamed up with U-M materials science and design alumni analyst Jonathan Schwartz, microscopy scientist Yi Jiang, and AI and materials science master Huihuo Zheng, both of Argonne National Laboratory, to assemble calculations that could rapidly and precisely transform electron microscopy pictures into 3D perceptions.

When the calculations were finished, Cornell teacher of applied and designed material science David Muller and Peter Ericus, a staff researcher at the Berkeley Lab’s Molecular Foundry, worked with Hovden to plan a UI that would uphold the new capacities.

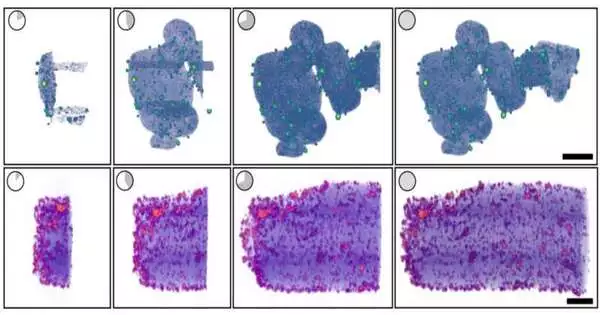

Finally, Hovden worked with materials science and design professor Nicholas Kotov, undergrad information researcher Jacob Pietryga, biointerfaces research individual Anastasiia Visheratina, and compound designing examination individual Prashant Kumar, all at U-M, to create a nanoparticle that could be used for true testing of the new capacities, to both ensure their exactness and hotshot their abilities.They chose a nanoparticle molded like a helix, around 100 nanometers wide and 500 nanometers in length. The new variant of tomviz filled in as expected; in no time, it created a picture that was shadowy yet definite enough for the scientists to make out key subtleties like the way the nanoparticle turns, known as chirality. Around 30 minutes after the fact, the shadows settled into an itemized, three-layered perception.

The source code for the new beta variant of Tomviz is openly accessible for download at GitHub. Hovden accepts it will open additional opportunities to fields past materials-related research; fields like science are likewise ready to profit from admittance to ongoing electron tomography. He also believes that the project’s “product as science” approach will spur new advances in science and programming development.

“We truly have an interdisciplinary way to deal with research at the convergence of software engineering, material science, physical science, and science,” Hovden said. It’s one thing to make truly cool calculations that you and your alumni understudies know how to utilize. It’s something else in the event that you can empower labs across the world to do these cutting-edge things. “

Kitware partners on the task were Chris Harris, Brainna Major, Patrick Avery, Utkarsh Ayachit, Berk Geveci, Alessandro Genova, and Hanwell. Kotov is likewise the Irving Langmuir Distinguished University Professor of Chemical Sciences and Engineering, Joseph B., Florence V. Cejka Professor of Engineering, and a teacher of compound design and macromolecular science and design.

“I’m excited about all the new science disclosures and 3D perceptions that will emerge from the material science and microscopy local areas with our new ongoing tomography system,” Schwartz said.

More information: Jonathan Schwartz et al, Real-time 3D analysis during electron tomography using tomviz, Nature Communications (2022). DOI: 10.1038/s41467-022-32046-0

Journal information: Nature Communications