Materials that are major areas of strength for both lightweights could further develop everything from vehicles to body protective layers. However, typically, the two characteristics are fundamentally unrelated. Presently, College of Connecticut scientists and partners have fostered an uncommonly solid, lightweight material utilizing two impossible structural blocks: DNA and glass.

“For the given thickness, our material is the most grounded known,” says Seok-Charm Lee, a materials researcher at UConn. Lee and associates from UConn, Columbia College, and Brookhaven Public Lab revealed the subtleties on July 19 in Cell Reports Actual Science.

Strength is relative. Iron, for instance, can take seven tons of strain per square centimeter. But at the same time, it’s extremely thick and weighty, weighing 7.8 grams per cubic centimeter. Different metals, like titanium, are more grounded and lighter than iron. Furthermore, certain amalgams joining different components are significantly more grounded. Solid, lightweight materials have been considered for lightweight body covering, better clinical gadgets, and more secure, quicker vehicles and planes.

“The ability to design and mineralize 3D framework nanomaterials using DNA opens up enormous possibilities for engineering mechanical properties. However, much more research is needed before we can use it as a technology.”

Oleg Gang and Aaron Mickelson, nanomaterials scientists at Columbia University

The simplest method for expanding the scope of an electric vehicle, for instance, isn’t to augment the battery but instead to make the actual vehicle lighter without forfeiting security and lifetime. Be that as it may, customary metallurgical strategies have hit a cutoff lately, and materials researchers have needed to get much more imaginative to foster new lightweight, high-strength materials.

Presently, Lee and his partners report that by building a structure out of DNA and then covering it with glass, they have made an extremely impressive material with an exceptionally low thickness. Glass could appear to be an astounding decision, as it breaks without any problem. Notwithstanding, glass for the most part breaks due to a blemish—like a break, scratch, or missing iota—in its design. A perfect cubic centimeter of glass can endure 10 tons of strain, multiple times the tension that collapsed the Ocean gate Titan sub close to the Titanic last month.

Making a huge piece of glass without flaws is extremely challenging. Yet the specialists knew how to make tiny, immaculate pieces. However long glass is under a micrometer thick, it’s quite often impeccable. What’s more, since the thickness of glass is a lot lower than that of metals and ceramics, any designs made of immaculate nano-sized glass ought to be solid and lightweight.

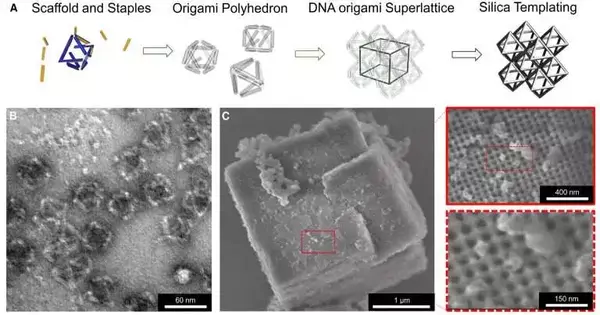

The group made a design of self-gathering DNA. Practically like Magnatiles, bits of DNA of explicit lengths snapped themselves together into a skeleton of the material. Imagine the casing of a house or building, however, made of DNA.

Oleg Group and Aaron Mickelson, nanomaterials researchers at Columbia College and Brookhaven’s Middle for Utilitarian Nanomaterials, then, at that point, covered the DNA with an exceptionally meager layer of glass-like material two or three hundred molecules thick. The glass just barely covered the strands of DNA, leaving an enormous piece of the material volume as unfilled space, similar to the rooms inside a house or building.

The DNA skeleton supported the dainty, immaculate covering of glass, making the material extremely impressive, and the voids comprising the greater part of the material’s volume made it lightweight. Subsequently, glass nanolattice structures are multiple times stronger yet multiple times thinner than steel. This surprising mix of lightweight and high strength has never been accomplished.

“The capacity to make planned 3D system nanomaterials involving DNA and mineralize them opens gigantic doors for designing mechanical properties. Be that as it may, much exploration work is yet required before we can utilize it as an innovation,” says Pack.

The group is right now working with a similar DNA structure but substituting much more grounded carbide pottery for glass. They have plans to explore different avenues regarding different DNA designs to see which makes the material most grounded.

Future materials, in view of this equivalent idea, will have extraordinary commitment as energy-saving materials for vehicles and different gadgets that focus on strength. Lee accepts that DNA origami nanoarchitecture will open another pathway to making lighter and more grounded materials than we have ever envisioned.

“I love Iron Man films, and I have consistently considered how to make a superior protective layer for Iron Man. It should be extremely light for him to fly faster. Safeguarding him from adversaries’ attacks should be an area of extreme strength. Our new material is multiple times lighter but also multiple times more grounded than steel. Along these lines, our glass nanolattices would be obviously superior to some other primary materials to make a better protection for Iron Man.”

More information: Aaron Michelson et al, High-strength, lightweight nano-architected silica, Cell Reports Physical Science (2023). DOI: 10.1016/j.xcrp.2023.101475