Asphaltenes, a result of the creation of raw petroleum, are a waste material with potential. Rice College is not committed to locating it by converting the carbon-rich asset into valuable graphene.

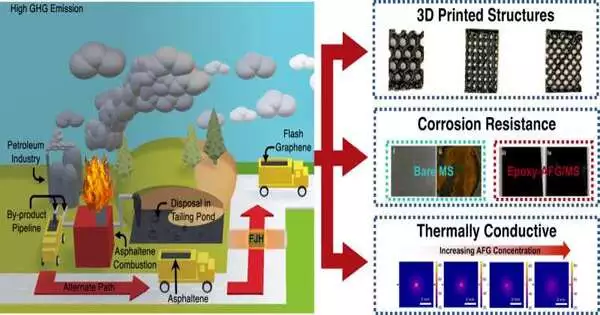

Muhammad Rahman, an associate professor of materials science and nanoengineering at Rice, is transforming asphaltenes into turbostratic (approximately adjusted) graphene and incorporating it into composites for warm, anti-erosive, and 3D-printing applications.

The interaction actually makes use of material that would otherwise be recycled as fuel or disposed of in lakes and landfills.At any rate, utilizing a portion of the world’s supply of more than 1 trillion barrels of asphalt as a feedstock for graphene would be great for the climate too.

“The government has put pressure on the petroleum industries to address this issue. Because there are billions of barrels of asphaltene accessible, we started working on this project to determine if we could create carbon fiber. This prompted us to consider producing graphene using flash Joule heating.”

Rice graduate student and co-lead author M.A.S.R. Saadi

“Asphaltene is a major headache for the oil business, and I figure there will be a great deal of interest in this,” said Rahman, who portrayed the cycle as both a versatile and feasible method for diminishing fossil fuel byproducts by copying asphaltene.

Rahman is the lead author of the paper in Science Advances, co-authored by Rice scientific expert James Visit, whose lab created the Joule heating streak, materials researcher Pulickel Ajayan, and Md. Golam Kibria, an associate teacher of substances and oil design at the College of Calgary, Canada.

Asphaltenes are 70% to 80% carbon as of now. The Rice lab consolidates it with around 20% of dark carbon to add conductivity and blazes it with a shock of power, transforming it into graphene in under a moment. Different components in the feedstock, including hydrogen, nitrogen, oxygen, and sulfur, are vented away as gases.

“We attempt to keep the carbon-dark substance as low as conceivable in light of the fact that we need to expand the use of asphalt,” Rahman said.

“The public authority has been coming down on the oil businesses to deal with this,” said Rice graduate understudy and co-lead creator M.A.S.R. Saadi. “There are billions of barrels of accessible asphalt, so we started chipping away at this undertaking basically to check whether we could make carbon fiber.” That prompted us to consider trying to make graphene using streak Joule heating.”

Assuming that Visit’s cycle worked as well on asphalt as it did on other feedstocks such as plastic, electronic waste, tires, coal fly debris, and even vehicle parts, the experts began making things with their graphene.

Saadi, who works with Rahman and Ajayan, blended the graphene into composites and, afterward, polymer inks headed for 3D printers. “We’ve improved the ink rheology to show that it is printable,” he said, taking note of the fact that the inks have something like 10% of graphene blended in. Mechanical testing of printed objects is approaching, he said.

Rice graduate understudy Paul Advincula, an individual from the Visit Lab, is the co-lead creator of the paper.

More information: MASR Saadi et al, Sustainable Valorization of Asphaltenes via Flash Joule Heating, Science Advances (2022). DOI: 10.1126/sciadv.add3555. www.science.org/doi/10.1126/sciadv.add3555

Journal information: Science Advances