Under the direction of Professor Jong-Sung Yu, the Department of Energy Science and Engineering at DGIST’s research team has created a low-temperature method to create a highly graphitized carbon support that will significantly lengthen the life of hydrogen fuel cells. They anticipate that the study’s findings will increase the likelihood of commercialization for use in drones, water electrolysis batteries, and fuel cells for cars. The research is presented in the Applied Catalysis B: Environmental journal.

The need for environmentally friendly energy is growing, which is why hydrogen fuel cells are becoming more significant. As a result, research is being done to enhance the functionality and lifespan of hydrogen fuel cells, with a focus on ways to make platinum (Pt) a more active and effective fuel cell catalyst.

Fuel cell catalysts made of platinum are very efficient, but they are also expensive and have poor long-term durability. To deal with this, the U.S. Department of Energy is working hard to find solutions to these problems so that fuel cells can be used widely.

“To address the limits of existing carbon material production methods, a low-temperature synthesis strategy was proposed, and a new carbon support was synthesized as a result. It was applied to the first freshly created fuel cell catalyst that met the US Department of Energy’s durability specifications for both the platinum catalyst and the carbon support.”

Professor Yu of the Department of Energy Science and Engineering at DGIST.

The platinum-based catalyst’s instability and its carbon support are the main factors affecting long-term durability. High voltages produced during start-stop operations degrade the carbon supports, resulting in the supported platinum being detached and a drop in electrical conductivity. It is urgently necessary to find a solution to this decline in fuel cell performance, but because making carbon materials more durable is difficult, most research focuses on platinum-based catalysts.

Carbon materials become more durable as their graphiticity increases. It is challenging to induce characteristics that can enhance fuel cell performance because graphiticity can only be increased by high-temperature heat treatment (2,000°C or higher). As a result, a new synthesis method is required that can produce useful properties of carbon materials in a less energy-intensive way.

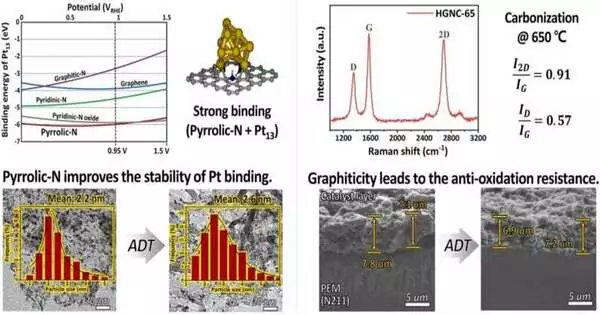

In order to introduce high graphiticity even at the relatively low temperature of 650°C, Professor Yu’s research group created a new synthesis technique. It is a quick procedure that involves heating magnesium (Mg) powder with an organic precursor that contains nitrogen. By utilizing the reducing power of magnesium, the treatment’s temperature was reduced in an unprecedented way. In addition, magnesium served as its own template to give the highly graphitized carbon material a porous structure and a high specific surface area. It was established that the low-temperature process introduced a sufficient amount of nitrogen doping into the carbon material.

The team’s low-temperature magnesium-based process created an exceptional carbon support that satisfied the three requirements for an electrochemical catalyst: graphiticity for stability and electric conductivity, excellent porosity and surface area, and heteroatom doping.

The research team anticipated that the high graphiticity would increase the carbon support’s durability and that the heteroatom doping, by stabilizing bonds with platinum nanoparticles, would effectively prevent the dissolution of platinum. In order to confirm this, they used the U.S.-proposed protocol to assess the platinum catalyst’s and the carbon support’s longevity. S. Energy Department

Both the catalyst and the support demonstrated stability that exceeded U.S. goals. The Department of Energy The platinum-highly graphitized nitrogen-doped carbon (Pt-HGNC) catalyst only experienced a 24 percent loss and was 3 1/2 times more stable than a platinum-carbon (Pt-C) catalyst. The durability target for the carbon support was a 40 percent loss in activity per mass of platinum.

They “proposed a low-temperature synthesis strategy to overcome the limitations of existing carbon material production methods, and through this, a new carbon support was synthesized,” according to Professor Yu of the Department of Energy Science and Engineering at DGIST. It was applied to a newly created fuel cell catalyst, which is the first to meet U.S. They “expect to contribute to the commercialization of fuel cells for vehicles and power generation and the improvement of the durability of fuel cell catalysts, meeting both the platinum catalyst’s and the carbon support’s durability standards established by the Department of Energy.

More information: Ha-Young Lee et al, Low temperature synthesis of new highly graphitized N-doped carbon for Pt fuel cell supports, satisfying DOE 2025 durability standards for both catalyst and support, Applied Catalysis B: Environmental (2022). DOI: 10.1016/j.apcatb.2022.122179