Nanosheets are finely organized two-layered materials and have incredible potential for advancement. They are fixed on top of one another in layered precious stones, and must initially be isolated from one another so they can be utilized, for instance, to channel gas combinations or for effective gas hindrances. An examination group at the University of Bayreuth has now fostered a delicate, harmless to the ecosystem cycle for this troublesome course of delamination that might be utilized on a modern scale. This is the first occasion when a gem from the mechanically appealing gathering of zeolites has been made usable for an expansive field of likely applications.

The delamination cycle created in Bayreuth under the course of Prof. Dr. Josef Breu is portrayed by the way that the designs of the nanosheets disengaged from one another stay flawless. It also enjoys the benefit that it tends to be utilized at a typical room temperature. The analysts present their outcomes exhaustively in Science Advances.

The two-layered nanosheets, which lie on top of one another in layered gems, are kept intact by electrostatic forces. For them to be utilized for innovative applications, the electrostatic powers should be preserved, and the nanosheets separated from one another. A technique especially reasonable for this is osmotic enlarging, in which the nanosheets are constrained to be separated by water and the particles and particles break up in it. In any case, it has just been feasible to apply it to a couple of kinds of gems, including some earth minerals, titanates, and niobates. For the gathering of zeolites, be that as it may, whose nanosheets are exceptionally fascinating for the creation of useful layers because of their silicate-containing fine designs, the component of osmotic enlarging has not yet been appropriate.

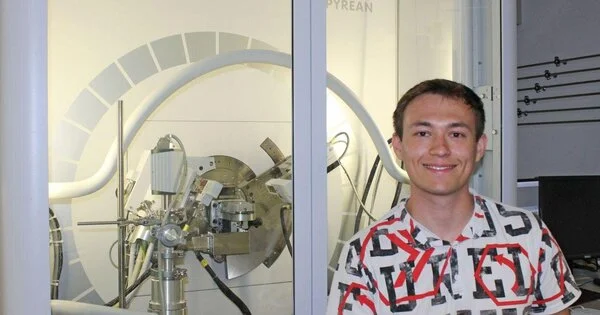

Credit: Chr. Wißler

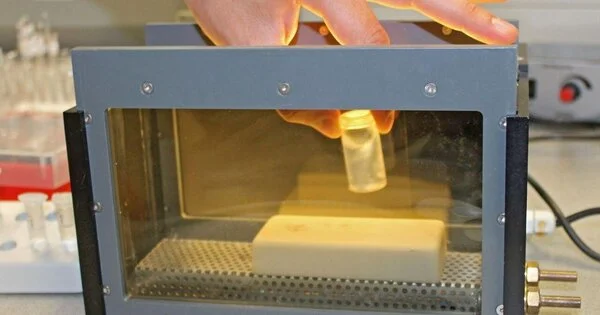

The Bayreuth research group has now — without precedent for interdisciplinary cooperation — figured out how to involve osmotic expansion in the delicate division of ilerite gems, which have a place in the gathering of zeolites. Simultaneously, huge sugar particles are first embedded into the thin spaces between the nanosheets. Consequently, the nanosheets, which are stacked on top of one another and primarily adjusted, are isolated by water. Simultaneously, their divide turns out to be impressively bigger. Currently, the nanosheets can be driven further separated evenly every which way. Upon resulting drying, a strong surface is made that is made out of numerous nanosheets. These are stacked like playing a card game, covering just the edges and leaving a couple of holes. The width of the individual nanosheets is multiple times more notable than their thickness.

This presently opens up the chance of fixing a greater number of such surfaces on top of one another and developing new layered materials. The purpose of this cycle is that the nanostructures of the surfaces in the new material are balanced against one another. Thusly, their holes are not precisely on top of one another, with the goal that particles, particles, or even light signals can’t infiltrate the new material straightforwardly. This twisted, by and large, design empowers a wide scope of likely applications, for example, in bundling used to keep food fresh, in parts for optoelectronics, and conceivably even in batteries.