Polyethylene has various favorable properties, yet biodegradability isn’t one of them. A group of scientists has now developed a plastic that has comparable thermoplastic properties to polyethylene but is also biodegradable. According to the group’s review published in the journal Angewandte Chemie Global Version, the material in question is a semicrystalline polyester that separates completely to its beginning materials utilizing gentle compound or natural cycles.

High-thickness polyethylene (HDPE) is an especially impressive and solid material. It owes its thermoplastic properties to the inner design of its sub-atomic chains, which are organized in a glasslike way with added fascination because of van der Waals forces. The atomic chains are likewise unadulterated hydrocarbons. The mix of crystallinity and hydrocarbon content means microorganisms, which could possibly degrade the plastic, can’t get to the chains to split them up.

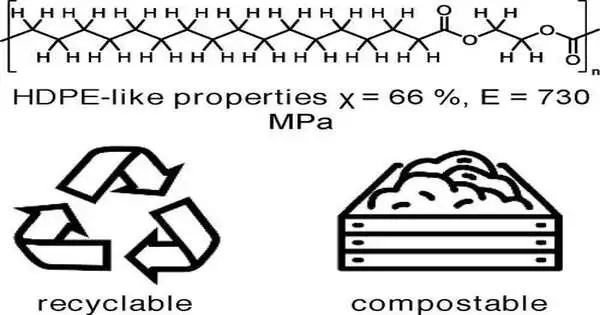

The examination gathering of Stefan Mecking and partners at the College of Konstanz, Germany, has now fostered a polyester that has comparable crystallinity to HDPE and furthermore holds its useful mechanical properties. Polyesters, like polyethylene, contain useful groups that could theoretically be degraded artificially or enzymatically.Nonetheless, under typical conditions, the more glasslike a polyester is (i.e., the more like HDPE), the less promptly it tends to be biodegraded.

“This building component is extremely frequent in polyesters. It provides you a high melting point, but it also boosts the degradability of these polyethylene-like compounds.”

Stefan Mecking and colleagues, at the University of Konstanz, Germany,

The group was thus naturally amazed by how rapidly their glasslike polyester degraded when presented to proteins. “We tried debasement with naturally occurring proteins, and it was much faster than with our reference material,” Mecking explains.Not only did enzymatic reactions degrade the material; soil microorganisms were also capable of completely composting it.

Yet, what could it be that makes this polyester so especially biodegradable? The group had the option of recognizing the huge commitment of ethylene glycol, one of the building blocks of polyester. Mecking adds: “This building block is very normal in polyesters.” “It gives you a high softening point, yet it likewise increases degradability in these polyethylene-like materials.”

Due to its great compound and natural degradability, along with its mechanical properties, the new polyester could track down applications as a recyclable thermoplastic material with negligible ecological effect. The ultimate objective is closed-circuit compound recycling to separate the plastic into its natural substances and produce new plastics, Mecking adds. The additional advantage of the group’s plastic is that, assuming any materials truly do get into the climate in spite of this closed circle, they can biodegrade and leave no enduring effect.

More information: Marcel Eck et al, Biodegradable High‐Density Polyethylene‐like Material, Angewandte Chemie International Edition (2022). DOI: 10.1002/anie.202213438

Journal information: Angewandte Chemie International Edition