Scientists have shown that 3D laser printing can be utilized to create a great, complex polymer optical gadget directly on the end of an optical fiber. This type of miniature optical device, with nuances less than the width of a human hair, could provide a very simple and low-cost method of fitting light bars for a variety of applications.

“Correspondence advances, the web and numerous different applications depend on optical strands,” said research group pioneer Shlomi Lightman from Soreq Atomic Exploration Place in Israel. “At the point when light emerges from the fiber, huge massive optical components are commonly used to guide it to the following area. “Our methodology limits both the size and cost for this cycle by coordinating the steering system into the actual fiber.”

Lightman and colleagues describe how they made the small multi-part bar shaper on a fiber in the journal Optics Letters.The gadget transforms ordinary laser light into a bent Bessel bar that conveys orbital rakish force and doesn’t grow in space like normal light shafts.

“Optical fibers are used in communication technology, the internet, and a variety of other applications. When light exits the fiber, it is normally routed to the next destination using large bulky optical components. By incorporating the routing mechanism within the fiber itself, we reduce both the size and expense of this operation.”

Shlomi Lightman from Soreq Nuclear Research Center in Israel.

The analysts created the whole miniature optical gadget in under 5 minutes. The fiber along with the miniature optical gadget cost under $100, about a 10th of what a standard magnifying instrument objective focal point that carries out a comparable role could cost.

Lightman said, “The capacity to make a Bessel bar straightforwardly from an optical fiber could be utilized for molecule control or fiber-coordinated invigorated outflow exhaustion (STED) microscopy, a method that produces super-goal pictures.” “By printing a clever little design on it, our creation strategy could also be used to upgrade a cheap focal point to a more savvy focal point.”

Accuracy arranging

To make the small optical gadgets, the scientists utilized a creation method called 3D direct laser printing. This uses a laser bar with femtosecond heartbeats to make two-photon retention in a photosensitive optical material. The small volumes where two-photon retention happens go strong, giving a method for making high-goal 3D components.

Although this 3D direct laser printing has been utilized for quite a while, it is hard to get the scale and arrangement right while creating such small optics on a fiber tip. “We had the option to beat this obstacle by performing profoundly exact 2D and 3D recreations before we started the creation cycle,” said Lightman. “Also, we needed to painstakingly ponder how to coordinate the optical components with one another and afterward adjust them to the fiber center.”

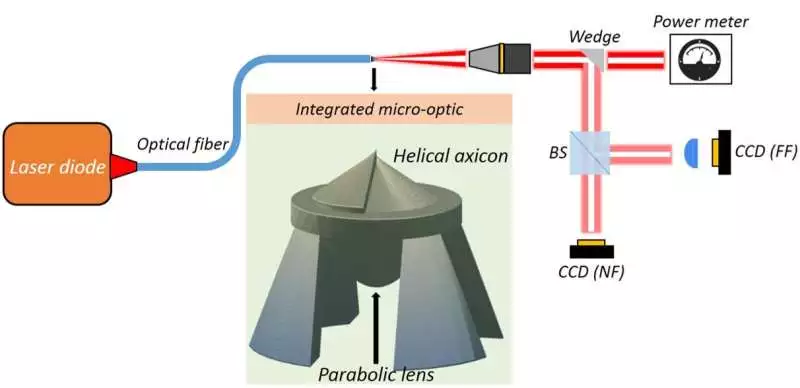

The scientists made an optical estimating framework to examine the appearance of bars molded by the created gadget. The bar showed that low diffraction and laser powers could arrive at near 10 MW/cm2 prior to harming the created miniature optical gadget. Shlomi Lightman, Soreq Atomic Exploration Place

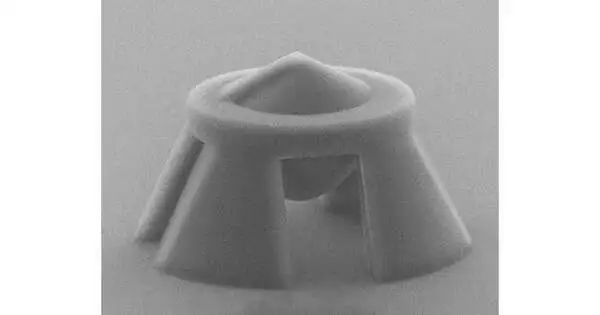

After cautious arranging in view of the recreations, the scientists utilized a business 3D direct laser composing framework and a high optical quality photosensitive polymer to print a 110-micron-tall optical gadget 60 microns in width and 110 microns tall on the end of a solitary mode optical fiber. The gadget included both an explanatory focal point for light collimation and a helical axicon focal point to bend the light. This transformed light, leaving the fiber into a bent Bessel bar.

Excellent light distribution

To dissect the nature of the created optical gadget, the scientists assembled an optical estimating framework to catch the molded bar spreading from the altered fiber. They noticed low diffraction in the bar, and that implies that it very well may be helpful for applications like STED microscopy and molecule control.

They also discovered that the laser power could reach near 10 MW/cm2 before harming the created miniature optical device.This demonstrated that, despite the fact that the device was made of polymer, which is more vulnerable to heat harm from high powers than glass, it could still be used to generate somewhat higher laser power.

Since scientists have shown that exact multi-component miniature optics can be made utilizing this immediate 3D laser printing strategy, they are trying different things by utilizing photosensitive materials that contain a low level of polymer. These materials could make it conceivable to create better optics that have a more extended time span of usability and are more impervious to high laser powers compared with polymer materials.

More information: Shlomi Lightman et al, Vortex-Bessel beam generation by 3D direct printing of an integrated multi-optical element on a fiber tip, Optics Letters (2022). DOI: 10.1364/OL.470924

Journal information: Optics Letters