Bioactive mixtures present for the most part in products of the soil carry out various substantial roles connected with wellbeing and prosperity. Antioxidant, diabetes, anti-aging, and cancer-fighting properties are among their effects.

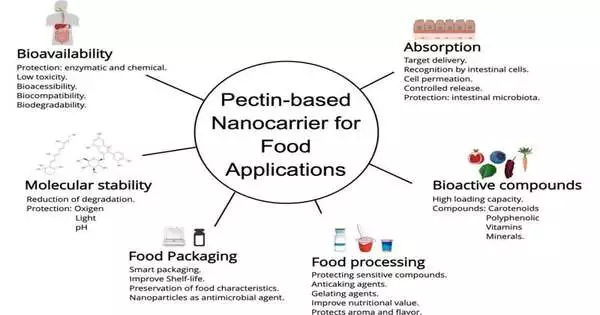

Bioactive compounds’ bioavailability—the percentage that enters the bloodstream after being absorbed—is the subject of numerous studies aimed at improving the organism’s ability to absorb them and increasing their bioavailability. The compounds can be packaged on the nanometric scale (a nanometer is one billionth of a meter) by coating them with another material. The term “nanoencapsulation” refers to the method that guarantees the compounds’ slow release, allowing them to withstand the attacks of bacteria in the gut microbiome and take longer to digest.

“We employed pectin derived from citrus fruit albedo and peel remnants that was pure enough for human consumption while excluding any form of dangerous chemical,”

João Paulo Fabi, one of the authors and a professor at FCF-USP.

One of these studies was carried out by a pair of researchers at the School of Pharmaceutical Sciences (FCF-USP) of the University of Sao Paulo in Brazil. They have written a number of articles on the topic while working at the school’s Department of Food Science and Experimental Nutrition. The most recent one, which was published in the International Journal of Biological Macromolecules, is a review of the literature on pectin-based nanoencapsulation and a description of a novel technology developed at the Food Research Center (FoRC), a Research, Innovation, and Dissemination Center (RIDC).

Joo Paulo Fabi, one of the authors and a professor at FCF-USP, stated, “We used pectin extracted from residues of citrus fruit albedo and peel, with a degree of purity permitting human ingestion and excluding any kind of hazardous chemical.” The layer of white, spongy material inside the peels of lemons and oranges, for instance, is called albedo.

“In addition to our literature review, we describe a novel pectin-based nanoencapsulation technology for bioactive compounds. He added that lysozyme is “a safely edible substance obtained from egg white and used to enhance the stability of the end product.” “This entails producing a pectin-lysozyme complex as a protective outer layer for a highly sensitive bioactive compound called anthocyanin,” he explained.

Anthocyanins are pigments in the flavonoid family that dissolve in water. They are phenolic compounds that are found in all plants. They are what give flowers, fruit, leaves, stalks, and roots their red, blue, and purple hues.

Other water-soluble bioactive compounds could be encapsulated using the authors’ method, they claim. ” Thiécla Katiane Osvaldt Rosales, the other author, stated, “We tested anthocyanin because of its challenging sensitivity to many factors, such as light, temperature, pH, and gut bacteria.” At the Nuclear and Energy Research Institute (IPEN), she is working as a postdoctoral researcher at the moment.

Methodological advantages

According to the researchers, the main advantage of their method is that only pectin, lysozyme, and anthocyanin are added. In the laboratory, we combined three natural compounds to create a new product without adding salts, ligands, or anything potentially harmful. Additionally, the nanoparticles are not excessively small. Tiny nanoparticles have the ability to break through barriers and cell membranes, entering DNA and causing harm. “It’s safe to use the size we have,” Fabi said.

Rosales talked about the method they came up with to make the nanoparticles. Lysozyme and pectin are heated separately. They interact better when heated because their structure is partially altered by the rise in temperature. After that, they are quickly cooled to a temperature that won’t harm the sensitive and somewhat unstable anthocyanin. An hour of agitation is used to combine the three substances into an aqueous suspension. Encapsulated anthocyanin is the outcome. She continued, “The non-encapsulated contents are then separated by filtering the suspension.”

“We tested the parameters for the purpose of optimization, especially pH. If pH is too high, the anthocyanin breaks down,” says the company. “We take special care with factors like temperature and pH.” Also, it can’t be too low. She elaborated, “We discovered that the optimal pH for interaction between the molecules is 5.” We also looked at how long the agitation lasted and how strong it was. We made it a point to control every little thing because it affects the formation of stable particles. The method has been the subject of our patent application.

Results

At long last, the epitome was tested for viability in a processing framework recreated in the research center to copy the gastric and digestive stages. “As a result, some of the anthocyanin was digested and released at the end of gastric digestion; however, some of it remained in the nanostructure and had the potential to be absorbed by the nanostructure or released in the gut. We think this was a good result. Fractional and progressive delivery proposes assimilation of the compound beginnings before it enters the stomach, with the leftover nanoencapsulated portion presumably being delivered in the stomach or completely consumed with less underlying modification,” Rosales said.

Animal testing will be the next step. The results of our in vitro testing suggest that the nanoparticles can be consumed safely. We know that cells are able to absorb them without harm and that the anthocyanin and its properties are protected by pectin. We must now test it in animals, observing the oral ingestion process, anthocyanin absorption using specific markers for absorption, and the path the organism takes. She stated, “The biological destination and the extent of absorption must be confirmed.”

The primary use for the nanoparticles is as a food supplement. They can be added to food and dietary supplements, but to include them in a supplement, industrial mass production would be required, Fabi stated.

It is important to note that neither expensive procedures nor equipment are required by the method. The material for the nanocapsules, which is made from citrus peel byproducts, would also reduce manufacturing costs. Rosales stated, “The pectin we used in our study is commercially available and is utilized by the food industry, primarily for gel formation in jam or as a thickener.”

More information: Thiécla Katiane Osvaldt Rosales et al, Pectin-based nanoencapsulation strategy to improve the bioavailability of bioactive compounds, International Journal of Biological Macromolecules (2022). DOI: 10.1016/j.ijbiomac.2022.12.292