The University of Notre Dame’s Yanliang Zhang, an associate professor of mechanical and aerospace engineering, and colleagues Tengfei Luo and Alexander Dowling have created a novel, incredibly quick method for building energy-efficient, high-performance thermoelectric devices.

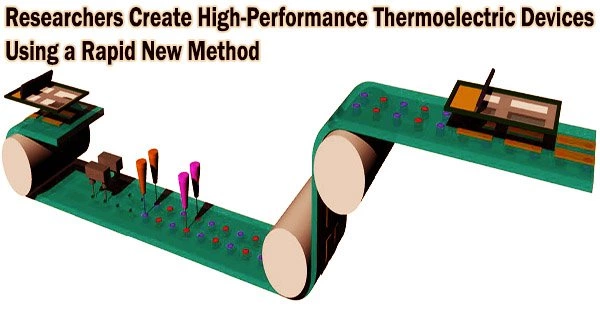

In less than a second, the innovative process sinters thermoelectric material using intense pulsed light (conventional sintering in thermal ovens can take hours). The team accelerated this process of sintering ultrafast but complicated nanoparticle inks into flexible devices by utilizing machine learning to identify the ideal circumstances for the operation.

The achievement was just published in the journal Energy and Environmental Science.

According to Zhang, flexible thermoelectric devices have excellent prospects for both solid-state cooling and the direct conversion of waste heat into power. Since they don’t produce greenhouse gases and don’t have moving components, they also have advantages as power and cooling sources and are quiet and dependable.

The lack of a technique for quick and affordable automated manufacture has prevented thermoelectric devices from being widely used, despite their potential widespread impact on energy and environmental sustainability.

The results can be applied to powering everything from wearable personal devices, to sensors and electronics, to industry Internet of Things. The successful integration of photonic flash processing and machine learning can be generalized to highly scalable and low-cost manufacturing of a broad range of energy and electronic materials.

Yanliang Zhang

Using ultrafast flash sintering with machine learning assistance, high-performance, environmentally friendly electronics may now be made considerably more quickly and inexpensively.

“The results can be applied to powering everything from wearable personal devices, to sensors and electronics, to industry Internet of Things,” Zhang said.

“The successful integration of photonic flash processing and machine learning can be generalized to highly scalable and low-cost manufacturing of a broad range of energy and electronic materials.”

Zhang is the principal investigator of the Advanced Manufacturing and Energy Lab at Notre Dame. Dowling, assistant professor of chemical and biomolecular engineering, and Luo, the Dorini Family Professor for Energy Studies both experts in machine learning contributed to this research, along with doctoral student Mortaza Saeidi-Javash (now assistant professor at California State Long Beach), doctoral student Ke Wang and postdoctoral associate Minxiang Zeng (now assistant professor at Texas Tech University).