Halide perovskites are a group of materials that stand out enough to be noticed for their predominant optoelectronic properties and expected applications in gadgets like superior-performance sun-based cells, light-radiating diodes, and lasers.

These materials have, to a great extent, been carried out in meager film or micron-sized gadget applications. On-chip light sources, photodetectors, and memristors are just a few of the remarkable applications that could be made possible by precisely integrating these materials at the nanoscale. Notwithstanding, accomplishing this coordination has been testing since this sensitive material can be harmed by regular creation and design strategies.

Individual halide perovskite nanocrystals can be grown on-site with precise control over location, down to less than 50 nanometers, using a method developed by MIT researchers to overcome this obstacle. The thickness of a sheet of paper is 100,000 nanometers. The size of the nanocrystals can likewise be precisely controlled through this method, which is significant on the grounds that size influences their qualities. Since the material is developed locally with the ideal elements, customary lithographic design advances that could cause harm are not required.

“As our research shows, developing new engineering frameworks for the integration of nanomaterials into functional nanodevices is critical. These approaches, by pushing beyond the established constraints of nanofabrication, materials engineering, and device design, can enable us to manipulate matter at extreme nanoscale dimensions, allowing us to realize unorthodox device platforms critical to addressing new technological needs.”

Farnaz Niroui, the EE Landsman Career Development Assistant Professor of Electrical Engineering.

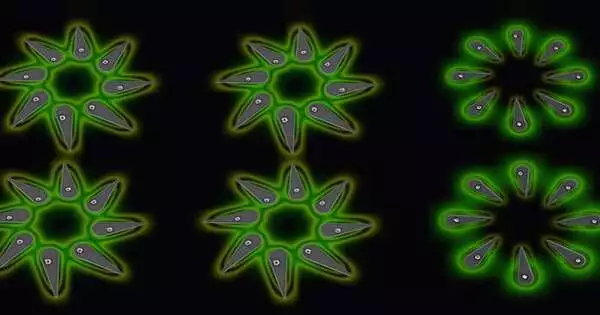

The nanocrystals can be integrated into functional nanoscale devices thanks to the method’s scalability, adaptability, and compatibility with standard fabrication steps. The analysts utilized this to create varieties of nanoscale light-emanating diodes (nanoLEDs)—small gems that discharge light when electrically actuated. High-density, high-resolution displays for augmented and virtual reality, lensless microscopes, novel quantum light sources, and optical communication and computing could all benefit from such arrays.

“As our work shows, it is basic to foster new design structures for joining nanomaterials into utilitarian nanodevices.” These techniques can allow us to manipulate matter at the extreme nanoscale dimensions, helping us realize unconventional device platforms important to addressing emerging technological needs,” says Farnaz Niroui, the EE Landsman Career Development Assistant Professor of Electrical Engineering and Computer Science (EECS), a member of the Research Laboratory of Electronics (RLE), and senior author of a new paper describing the work. “These techniques can allow us to move beyond the traditional boundaries of nanofabrication, materials engineering, and device design.”

Lead author Patricia Jastrzebska Perfect, a graduate student in EECS, is one of Niroui’s co-authors. A graduate student in the Department of Chemical Engineering named Weikun “Spencer” Zhu; Sarah Spector, Roberto Brenes, Peter Satterthwaite, and Mayuran Saravanapavanantham, all EECS graduate students; Zheng Li, a postdoc at RLE; and Rajeev Ram, an electrical engineering professor. Nature Communications will publish the research.

Using conventional nanoscale fabrication methods, incorporating halide perovskites into on-chip nanoscale devices is extremely challenging for the tiny crystals. Using solvents that could harm the material, lithographic processes can be used to pattern a thin film of fragile perovskites. In another methodology, more modest precious stones are first shaped in arrangement and then picked and set from arrangement in the ideal example.

According to Niroui, “in both cases, there is a lack of control, resolution, and integration capability,” which restricts the material’s application to nanodevices.

All things being equal, she and her group fostered a way to deal with “developing” halide perovskite gems in exact areas straightforwardly onto the ideal surface where the nanodevice will then, at that point, be created.

The localization of the solution used in the growth of the nanocrystals is fundamental to the procedure. They use a nanoscale template with tiny wells that contain the chemical process by which crystals grow to accomplish this. They change the outer layer of the layout and within the wells, controlling a property known as wettability,” so an answer containing perovskite material won’t pool on the format surface and will be restricted inside the wells.

She continues, “Now, you have these very small and deterministic reactors inside of which the material can grow.”

Furthermore, that is precisely what occurs. They apply an answer containing halide perovskite development material to the format, and, as the dissolvable vanishes, the material develops and frames a minuscule precious stone in each well.

A flexible and tunable method

The scientists found that the state of the wells plays a basic role in controlling the nanocrystal’s positioning. The crystals have an equal chance of being placed in each of the four corners of a square well because of the influence of nanoscale forces. That might be sufficient for some applications, but for others, the nanocrystal placement needs to be more precise.

The researchers were able to engineer these nanoscale forces in such a way that a crystal is preferentially placed in the desired location by altering the shape of the well.

The nanocrystal experiences a pressure gradient inside the well as the solvent evaporates, resulting in a directional force, the precise direction of which is determined by the asymmetric shape of the well.

According to Niroui, “this enables us to have very high precision, not only in growth but also in the placement of these nanocrystals.”

Additionally, they discovered that they could control the size of the crystals that formed within a well. Crystals can become larger or smaller by altering the size of the wells to accommodate more or less growth solution inside.

By constructing precise nanoLED arrays, they demonstrated the method’s efficacy. In this methodology, each nanocrystal is made into a nanopixel, which radiates light. These high-thickness nanoLED exhibits could be utilized for on-chip optical correspondence and registration, quantum light sources, microscopy, and high-goal shows for increased and augmented reality applications.

The researchers intend to investigate additional potential uses for these small light sources in the future. Additionally, they intend to test the limits of how small these devices can be and work toward their effective incorporation into quantum systems. The process provides additional opportunities for the creation of on-chip nanodevices based on halide perovskite in addition to nanoscale light sources.

In addition, their method makes it easier for researchers to study materials down to the individual nanocrystal level, which they hope will encourage others to study these and other unique materials further.

According to Jastrzebska-Perfect, “studying nanoscale materials through high-throughput methods frequently requires that the materials be precisely localized and engineered at that scale.” Our method has the potential to enhance how researchers investigate and tune the properties of materials for a variety of applications by providing that localized control.”

More information: On-site growth of perovskite nanocrystal arrays for integrated nanodevices, Nature Communications (2023). dx.doi.org/10.1038/s41467-023-39488-0