Researchers have created a new fabrication method that allows infrared (IR) glass to be mixed with other glasses and shaped into complicated, tiny structures. The method can be used to produce complicated infrared optics, which could make infrared imaging and sensing more widely available.

“IR-transmitting glass is vital for numerous applications, including spectroscopic techniques used to detect diverse materials and compounds,” said Yves Bellouard of the Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland. However, infrared glasses are difficult to produce, delicate, and easily degraded in the presence of moisture.

The researchers disclose their new technology in the journal Optics Express, which may be used to embed fragile infrared glasses inside a resilient silica matrix. The method may be used to generate nearly any interconnected 3D shape with features that are a micron or smaller. It works with a wide range of glasses, providing a novel option to fine-tune the qualities of 3D optics through delicate glass combinations.

Because it can be used to make infrared optical circuits and arbitrarily shaped IR micro-optics, our technique could open the door to a whole new range of new optical devices that were previously not possible due to the poor manufacturability of IR glass, said Enrico Casamenti, the paper’s first author. “These optics could be utilized for spectroscopic and sensing applications, as well as to develop an infrared camera small enough to fit into a smartphone.”

Combining materials

The novel fabrication approach evolved from prior work in which Bellouard’s research team cooperated with Andreas Mortensen’s team at EPFL to develop a way of producing highly conductive metals inside an insulating 3D silica substrate.

“Our team started looking for novel techniques to accomplish broadband light confinement in arbitrarily formed 3D optical circuits,” Bellouard explained. That’s when we decided to look into the idea of adapting a technology that we initially demonstrated using metal to make structures that blend two types of glass.

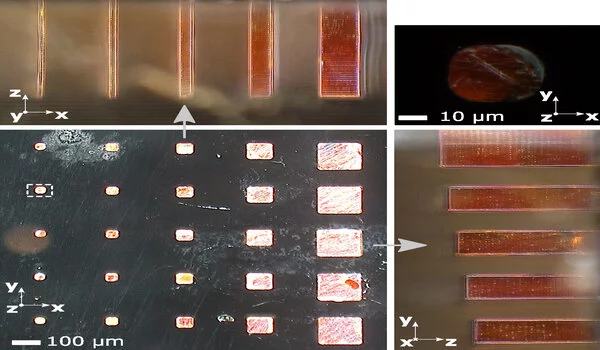

Using femtosecond laser-assisted chemical etching, the researchers begin by generating an arbitrarily formed 3D cavity inside a fused silica glass substrate. The pulsed beam of a femtosecond laser, which can be focused to a point one micrometer wide, is used to modify the glass structure, allowing the exposed portions to be removed with a chemical such as hydrofluoric acid.

Following this, the tiny cavity must be filled with another substance to form a composite construction. The researchers achieved this by utilizing a miniature version of pressure-assisted casting, in which a second material is heated and pressurized to flow and solidify within a network of carved silica chambers. The second material can be a metal, glass, or any other material that has a lower melting point than the carved silica substrate and does not react with silica glass.

“Our fabrication approach may be utilized to safeguard IR glass, bringing up new opportunities for micro-scale infrared optical circuits that are fully integrated into another glass substrate,”

Bellouard

Creating intricate optics

“Our fabrication approach may be utilized to safeguard IR glass, bringing up new opportunities for micro-scale infrared optical circuits that are fully integrated into another glass substrate,” Bellouard explained. In addition, because fused silica and chalcogenide have strong refractive-index contrast, we can shape these materials into IR waveguides that can carry light in the same way as optical fibers do.

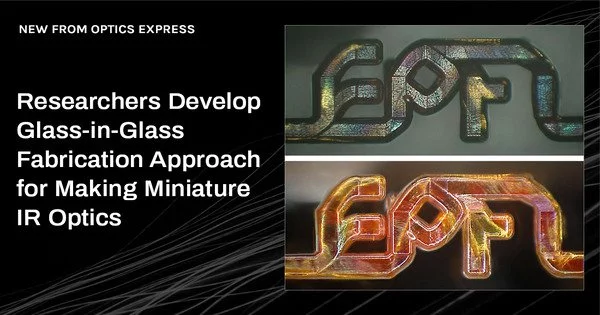

Using chalcogenide IR glass and a silica glass substrate, the researchers demonstrated the novel technology by manufacturing a variety of intricate forms, including the EPFL emblem. They also demonstrated, with the assistance of colleagues at ETH Zurich, that some of the structures they developed could be effectively employed for steering mid-IR light output by an 8-micron quantum cascade laser.

They are continuing to investigate the capabilities of the novel method in terms of combining different glasses and intend to test the composite parts in spectroscopy and other applications.