Scientists have fostered a metallic gel that is exceptionally electrically conductive and can be utilized to print three-layered (3D) strong items at room temperature. The paper, titled “Metallic Gels for Conductive 3D and 4D Printing,” has been accepted for publication in Matter.

Michael Dickey, co-corresponding author of a paper on the work and the Camille & Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University, states, “3D printing has revolutionized manufacturing, but we’re not aware of previous technologies that allowed you to print 3D metal objects at room temperature in a single step.” Manufacturing a wide range of electronic devices and components is now possible because of this.”

To make the metallic gel, the specialists start with micron-scale copper particles suspended in water. The researchers then add a small amount of a liquid metal at room temperature, an indium-gallium alloy. The mixture that is left over is then mixed together.

“Manufacturing has been transformed by 3D printing, however we are unaware of any earlier technologies that made it possible to print 3D metal items in a single step at room temperature.”

Michael Dickey, co-corresponding author of a paper on the work.

The liquid metal and copper particles basically stick to one another as the mixture is stirred, forming a metallic gel “network” within the aqueous solution.

“This gel-like consistency is significant in light of the fact that it implies you have a genuinely uniform circulation of copper particles all through the material,” Dickey says. ” This serves two purposes. First, it indicates that the particles in the network connect to form electrical pathways. What’s more, second, it implies that the copper particles aren’t settling out of arrangement and obstructing the printer.”

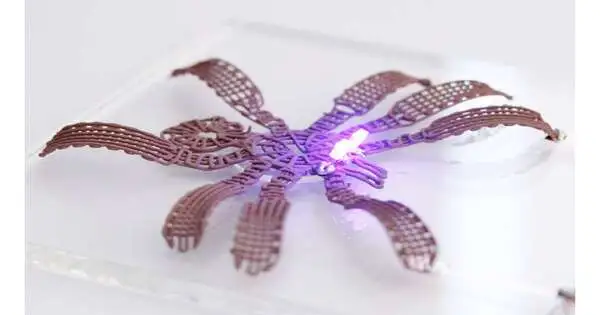

The resulting gel can be printed with a standard nozzle for 3D printing and keeps its shape after printing. The resulting three-dimensional object also retains its shape while becoming even more solid when dried at room temperature.

However, some interesting outcomes may occur if users choose to heat the printed object while it is drying. The analysts found that the arrangement of the particles impacts how the material dries.

If you printed a cylinder, for instance, when it dries, the sides would contract more than the top and bottom. The drying process is sufficiently sluggish at room temperature to prevent structural changes in the object. However, the rapid drying can result in structural deformation if heat is applied, such as when it is placed under an 80°C heat lamp. By controlling the pattern of the printed object and the amount of heat that the object is exposed to while drying, you can make a printed object change shape after it has been printed because this deformation is predictable.

According to Dickey, “Ultimately, this kind of four-dimensional printing—the traditional three dimensions plus time—is one additional tool that can be used to create structures with the desired dimensions.” However, the conductivity of this material is what we find most intriguing.

“The printed objects are highly conductive because they end up being up to 97.5 percent metal. It is evident that it is not as conductive as standard copper wire, but copper wire cannot be 3D printed at room temperature. Furthermore, what we’ve created is undeniably more conductive than whatever else can be printed. The applications here have us pretty excited.

Dickey states, “We are always happy to talk with potential collaborators about future directions for research.” He adds, “We are open to working with industry partners to explore potential applications.”

More information: Michael D. Dickey, Metallic Gels for Conductive 3D and 4D Printing, Matter (2023). DOI: 10.1016/j.matt.2023.06.015. www.cell.com/matter/fulltext/S2590-2385(23)00303-X