The primary means of combating climate change is clean energy. But, it’s difficult for solar and wind power to consistently generate enough energy for a stable power grid. Lithium-ion batteries, on the other hand, have a finite supply but can store energy.

“The advantage of a coal power plant is it’s very steady,” said Nian Liu, an assistant professor at the Georgia Institute of Technology. “If the power source fluctuates like it does with clean energy, it makes it more difficult to manage, so how can we use an energy storage device or system to smooth out these fluctuations?”

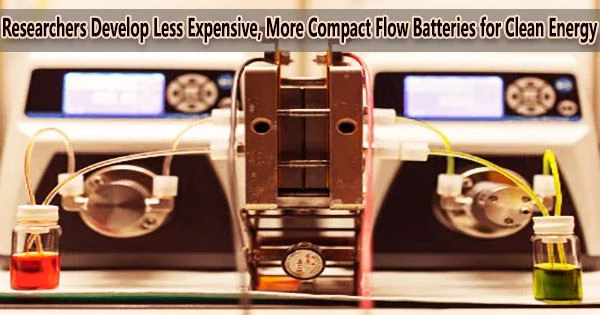

Flow batteries offer a solution. In this rechargeable battery, electrolytes are supplied from storage tanks through electrochemical cells. The existing flow battery technologies cost more than $200/kilowatt hour and are too expensive for practical application, but Liu’s lab in the School of Chemical and Biomolecular Engineering (ChBE) developed a more compact flow battery cell configuration that reduces the size of the cell by 75%, and correspondingly reduces the size and cost of the entire flow battery. The work might fundamentally alter how everything is fueled, from large commercial structures to private residences.

The all-Georgia Tech research team published their findings in the paper, “A Sub-Millimeter Bundled Microtubular Flow Battery Cell With Ultra-high Volumetric Power Density,” in Proceedings of the National Academy of Sciences.

Finding the Flow

Flow batteries get their name from the flow cell where electron exchange happens. The planar cell, which is their traditional design, necessitates large flow distributors and gaskets, increasing size and expense but lowering overall performance. The cell itself is also expensive. To reduce footprint and cost, the researchers focused on improving the flow cell’s volumetric power density (W/L-of-cell).

The superior performance of the SMBT was also demonstrated by finite element analysis. This simulation method will also be applied in our future study for cell performance optimization and scaling up.

Xing Xie

They used a sub-millimeter, bundled microtubular (SBMT) membrane constructed of a hollow fiber-shaped filter membrane, a design that is frequently employed in chemical separation. With this invention, pressure across the membranes that ions move through can be reduced without the requirement for extra support infrastructure.

“We were interested in the effect of the battery separator geometry on the performance of flow batteries,” said Ryan Lively, a professor in ChBE. “We were aware of the advantages that hollow fibers imparted on separation membranes and set out to realize those same advantages in the battery field.”

By using this idea, the researchers created an SMBT that cuts the distance between membranes by almost 100 times. The design’s microtubular membrane simultaneously distributes electrolytes without the requirement for substantial supporting components.

The volumetric power density is raised by the bundling of the microtubes, which reduces the space between the electrodes and membranes. The essential finding for optimizing the potential of flow batteries is this bundling arrangement.

Powering the Battery

The researchers used four alternative chemistries to confirm their new battery configuration: vanadium, zinc-bromide, quinone-bromide, and zinc-iodide. All chemistries are useful, but two stand out as particularly promising. Vanadium’s chemistry was the most developed, but it was also the least accessible because its reduced form is unstable in air. They discovered that zinc iodide has the highest energy density, making it the best choice for homes.

Zinc-iodide offered many advantages even compared to lithium: It is significantly simpler to recycle because it has fewer supply chain issues, can be converted into zinc oxide, and dissolves in acid.

This flow battery’s unusual electrochemical design turned out to be more potent than ordinary planar cells.

“The superior performance of the SMBT was also demonstrated by finite element analysis,” said Xing Xie, an assistant professor in the School of Civil and Environmental Engineering. “This simulation method will also be applied in our future study for cell performance optimization and scaling up.”

With zinc-iodide chemistry, the battery could run for more than 220 hours, or to > 2,500 cycles at off-peak conditions. It could also potentially reduce the cost from $800 to less than $200 per kilowatt hour by using the recycled electrolyte.

Building the Future of Energy

The scientists are already engaged in commercialization efforts, concentrating on creating batteries with other chemistries, such as vanadium, and expanding their capacity. The production of hollow fiber modules, which is now done manually, fiber by fiber, must be mechanized in order to scale. They eventually hope to deploy the battery in Georgia Tech’s 1.4-megawatt microgrid in Tech Square, a project that tests microgrid integration into the power grid and offers a living laboratory for professors and students.

The SBMT cells could also be used in fuel cells and other types of energy storage, including electrolysis. In some applications, the technique might even be improved by using cutting-edge materials and different chemistry.

“This innovation is very application-driven,” Liu said. “We have the need to reach carbon neutrality by increasing the percentage of renewable energy in our energy generation, and right now, it’s less than 15% in the U.S. Our research could change this.”