Clean energy is the main answer for environmental change. However, solar and wind power are incompatible in terms of producing enough energy to power a solid power matrix.On the other hand, lithium-particle batteries can store energy but are a restricted asset.

“The upside of a coal power plant is that it’s actually consistent,” said Nian Liu, an associate teacher at the Georgia Foundation for Innovation. Assuming the power source varies as it does with clean energy, it makes it more difficult to make due, so how might we utilize an energy stockpiling gadget or framework to streamline these changes?

Stream batteries offer an answer. Electrolytes move through electrochemical cells from capacity tanks in this battery-powered battery. The current advances in stream batteries cost more than $200 per kilowatt hour and are excessively costly for viable applications, yet Liu’s lab in the School of Compound and Biomolecular Designing (ChBE) fostered a more minimal stream battery cell setup that lessens the size of the cell by 75% and correspondingly decreases the size and cost of the whole stream battery. The work could upset how all that—from significant business structures to private homes—is fueled.

“The impact of the battery separator shape on the functionality of flow batteries was something we were interested in. We set out to achieve the same benefits in the battery field because we were aware of the benefits hollow fibers provided for separation membranes.”

Ryan Lively, a professor in ChBE.

The all-Georgia Tech research group distributed their discoveries in the paper, “A Sub-Millimeter Packaged Microtubular Stream Battery Cell With Super High Volumetric Power Thickness,” in Procedures of the Public Foundation of Sciences.

Tracking down the stream

Stream batteries get their name from the stream cell, which is where electron trade takes place. Their regular plan, the planar cell, requires massive streamers and gaskets, expanding in size and cost yet diminishing in general execution. The actual cell is likewise costly. To decrease impression and cost, the analysts zeroed in on further developing the stream cell’s volumetric power thickness (W/L-of-cell).

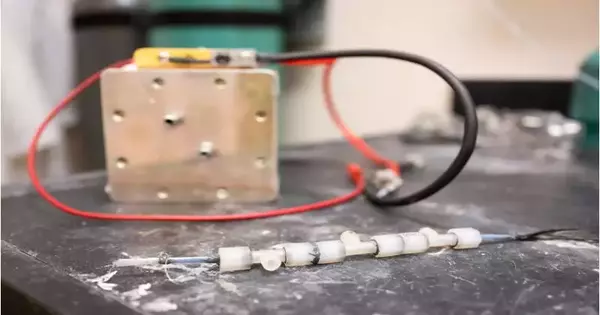

They went to a setup usually utilized in compound division—ssub-millimeter, packaged microtubular (SBMT) film—mmade of a fiber-molded channel layer known as an “empty fiber.” This development has a space-saving plan that can relieve strain across the films that particles go through without requiring an extra framework.

“We were keen on the impact of the battery separator math on the exhibition of stream batteries,” said Ryan Vivacious, a teacher in ChBE. “We knew about the benefits that empty strands granted on division films and set off to understand those equivalent benefits in the battery field.”

Applying this idea, the scientists developed a SMBT that reduces film-to-layer distance by just a few times. The microtubular film in the design acts as an electrolyte merchant at the same time, eliminating the need for bulky supporting materials.The packaged microtubes create a more limited distance among cathodes and films, expanding the volumetric power thickness. This packaging configuration is the vital revelation for boosting stream batteries’ true capacity.

Powering the battery

To approve their new battery setup, the analysts utilized four unique sciences: vanadium, zinc-bromide, quinone-bromide, and zinc-iodide. Although all sciences are beneficial, two in particular were encouraging. Vanadium was the most mature science, but it was also the most closed, and its reduced form is shaky in air. They found zinc iodide to be the most energy-rich choice, making it the best for private units. Zinc-iodide offered many benefits, even compared with lithium: It has a store network issue to a lesser extent, and it can also be converted into zinc oxide and broken down into corrosive, making it much easier to reuse.

This electrochemical solution for this novel state of the stream battery performed better than regular planar cells.

“The unrivaled exhibition of the SMBT was likewise shown by limited component examination,” said Xing Xie, an associate teacher in the School of Common and Natural Designing. “We will also use this recreation strategy in our future review for cell execution advancement and growth.”

With zinc-iodide science, the battery could run for over 220 hours, or > 2,500 cycles in off-peak circumstances. It may also be possible to reduce the cost from $800 to under $200 per kilowatt hour by reusing electrolyte.

Building the fate of energy

The analysts are now chipping away at commercialization, zeroing in on creating batteries with various sciences like vanadium and increasing their size. Scaling will require concocting a robotized cycle to make an empty fiber module, which is currently done physically, fiber by fiber. They at last desire to send the battery in Georgia Tech’s 1.4-megawatt microgrid to Tech Square, a task that tests microgrid mix into the power matrix and offers a living lab for teachers and understudies.

SBMT cells could also be used in other energy storage frameworks such as electrolysis and power modules.The innovation might be fortified with cutting-edge materials and different science in different applications.

“This development is very application-driven,” Liu said. “We want to arrive at carbon neutrality by expanding the level of sustainable power in our energy age, and at this moment, it’s under 15% in the U.S. “Our examination could change this.”

More information: Yutong Wu et al, A submillimeter bundled microtubular flow battery cell with ultrahigh volumetric power density, Proceedings of the National Academy of Sciences (2023). DOI: 10.1073/pnas.2213528120