As robots progressively join individuals on the plant floor, in stockrooms and somewhere else at work, sharing who will do which undertakings fills in intricacy and significance. Individuals are more qualified for certain undertakings, robots for other people. What’s more, at times, it is beneficial to invest energy helping a robot to do an errand now and receive the rewards later.

Specialists at Carnegie Mellon University’s Robotics Institute (RI) have fostered an algorithmic organizer that helps delegate undertakings to people and robots. The organizer, “Act, Delegate, or Learn” (ADL), thinks about a rundown of errands and concludes how best to relegate them. The scientists posed three inquiries: When should a robot act to finish a responsibility? When should an undertaking be designated for a human? What’s more, when should a robot gain proficiency with another undertaking?

The lead scientist and a Ph.D. understudy in the RI said there are expenses related to the choices made. For example, the time it takes a human to finish a job or help a robot follow through with a responsibility and the expense of a robot fizzling at an undertaking. “Considering that there are a large number of expenses, our framework will provide you with the ideal division of work.”

“There are costs connected with judgments made, such as the time it takes a human to perform a task or to teach a robot to do a task, as well as the cost of a robot failing at a task,” says the author.

Shivam Vats, the lead researcher

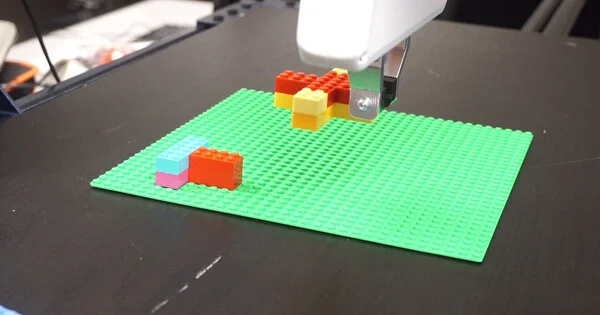

The cooperation could be valuable in assembling and gathering plants, for arranging bundles, or in any climate where people and robots team up to get the job done. The scientists tried the organizer in situations where people and robots needed to embed blocks into a stake board and stack portions of various shapes and sizes made of Lego blocks.

Utilizing calculations and programming to choose how to delegate and separate work isn’t new, in any event, when robots are essential for the group. This work is among the quick to incorporate robot learning into its thinking.

“Robots aren’t static any longer,” Vats said. “They can be improved and they can be instructed.”

Frequently, in assembling, an individual will physically control a mechanical arm to show the robot how to follow through with a job. Showing a robot takes time and, in this manner, has a high upfront expense. In any case, it may be advantageous in the long run if the robot can become acquainted with another ability.Some portion of the intricacy is choosing when it is ideal to show a robot as opposed to designating the errand to a human. This requires the robot to foresee what different undertakings it can finish in the wake of learning about another assignment.

Considering this data, the organizer changes the issue into a blended whole number program—a streamlining program usually utilized in booking, creation, or planning correspondence organizations—that can be settled productively by off-the-rack programming. The organizer performed better compared to customary models on all occasions and diminished the expense of getting done with the jobs by 10% to 15%.

The examination is distributed on arXiv.