Rensselaer Polytechnic Institute scientists have fostered an open method for making N95 facial coverings viable boundaries to microbes yet on-contact microorganism executioners. The antiviral and antibacterial veils might possibly be worn longer, causing less plastic waste as the covers needn’t be supplanted as often.

Helen Zha, partner teacher of compound and natural design and an individual from the Center for Biotechnology and Interdisciplinary Studies at Rensselaer (CBIS), teamed up with Edmund Palermo, academic partner of materials science and design and an individual from the Center for Materials, Devices, and Integrated Frameworks (cMDIS) at Rensselaer, to battle irresistible respiratory illness and ecological contamination with the ideal recipe to further develop facial coverings.

“This was a comprehensive materials engineering problem with a fantastic, diversified team of partners. We believe the research is a first step toward longer-lasting, self-sterilizing personal protection equipment like the N95 respirator. It may aid in the reduction of airborne pathogen transmission in general.”

Edmund Palermo, associate professor of materials science and engineering

“This was a complex materials design test with an incredible, varied group of partners,” Palermo said. “We think the work is an initial move toward longer-enduring, self-cleaning individual defensive gear like the N95 respirator.” It might assist in lessening the transmission of airborne microbes overall. “

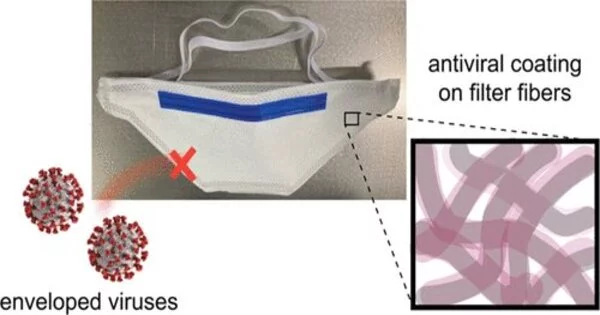

In research as of late distributed in ACS Applied Materials and Interfaces, the group effectively united a wide range of antimicrobial polymers onto the polypropylene channels utilized in N95 facial coverings.

“The dynamic filtration layers in N95 veils are delicate to compound change,” said Zha. “It can aggravate them regarding filtration, so they basically never again perform like N95s.” They’re made from polypropylene, which is hard to alter artificially. Another test is that you would rather not upset the fine organization of strands in these veils, which could make them harder to inhale through. “

Zha and Palermo, alongside different analysts from Rensselaer, Michigan Technological Institute, and Massachusetts Institute of Technology, covalently joined antimicrobial quaternary ammonium polymers to the fiber surfaces of nonwoven polypropylene textures utilizing bright (UV)-started uniting. The textures were given by Hills Inc. by the civility of Rensselaer graduate Tim Robson.

“The cycle that we created utilizes a truly basic science to make this non-draining polymer covering that can eliminate infections and microbes by basically tearing open their external layer,” said Zha. “It’s clear and a possibly versatile strategy.”

The group utilized just UV light and CH3CO in their cycle, which are broadly accessible, to make it simple to execute. What’s more, the cycle can be applied to currently made polypropylene channels instead of requiring the improvement of new ones.

The group saw a decline in filtration proficiency when the cycle was applied straightforwardly to the filtration layer of N95 veils, yet the arrangement is clear. The client could wear an unaltered N95 veil alongside another polypropylene layer with the antimicrobial polymer on top. Later on, producers could make a veil with the antimicrobial polymer integrated into the top layer.

Because of a National Science Foundation Rapid Response Research (RAPID) award, Zha and Palermo began their exploration in 2020 when N95 facial coverings were hard to find.

Medical care laborers were, in any event, reusing veils that were planned to be single-use. Quick forward to 2022, and facial coverings of various kinds are currently broadly accessible. Nonetheless, COVID rates are still high, the danger of one more pandemic in what’s to come is a particular chance, and single-use, expendable veils are stacking up in landfills.

“Ideally, we are on the opposite side of the COVID pandemic,” said Zha. Yet, this sort of innovation will be progressively significant. The danger of illnesses brought about by airborne organisms isn’t disappearing. The time has come for us to work on the exhibition and manageability of the materials that we use to safeguard ourselves.

“Joining compound gatherings that eliminate infections or microbes on contact with polypropylene is a savvy system,” said Shekhar Garde, Dean of the School of Engineering at Rensselaer. “Given the wealth of polypropylene in day to-day existence, maybe this system is helpful in numerous different settings, too.”

More information: Mirco Sorci et al, Virucidal N95 Respirator Face Masks via Ultrathin Surface-Grafted Quaternary Ammonium Polymer Coatings, ACS Applied Materials & Interfaces (2022). DOI: 10.1021/acsami.2c04165