Specialists from the Institute of Modern Physics (IMP) of the Chinese Academy of Sciences have acquired new outcomes on the nano-hardness and microstructure advancement of nano-organized titanium-aluminum-nitride (TiAlN) coverings under light. The results were published in Surface and Coatings Technology.

Change metal nitrides covering materials, particularly titanium nitride (TiN) coatings, display high hardness, scientific idleness, incredible wear and consumption resistance. These properties empower them to act as prevalent defensive coatings on atomic reactor structure materials. The outrageous radiation climate in atomic reactors might change their properties and corrupt their exhibition. Accordingly, focusing examination on the radiation reaction of the covering materials is fundamental.

Specialists at IMP have concentrated on the radiation-prompted changes in the properties of TiN-based covering materials. They chose TiAlN as an isostructure model material to investigate the relationship between illumination-actuated nano-hardness and microstructure advancement.

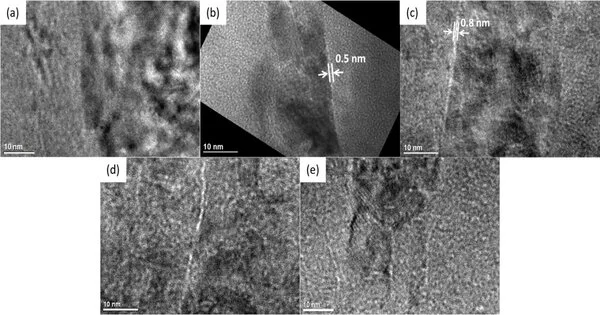

In the examination, the coatings were saved on the WFeNi substrate through the cathodic bend particle plating strategy, and the typical grain sizes of as-kept coatings were around 10 nm. The nitride (N) particle illumination investigations of the TiAlN coatings were performed at the 320 kV multi-discipline research stage with different temperatures and fluences.

Credit: TAI Pengfei

As per the scientists, there is no amorphization or stage change seen in every one of the illuminated examples, considerably under the harm level of 10 dpa at room temperature and higher temperatures, showing that the pre-arranged TiAlN covering has a decent light obstruction.

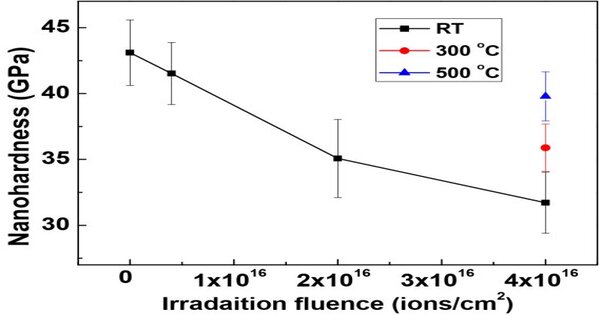

Also, they noticed huge radiation-actuated mellowing (RIS) impacts in every one of the lighted examples. The RIS impacts were enhanced in examples lighted at room temperature compared to the examples illuminated at high temperatures. The researchers observed numerous N rises in clearly illuminated examples and concluded that N bubbles situated along grain limits should be accountable for RIS impacts in nano-organized TiAlN covering.

More information: Pengfei Tai et al, Microstructure evolution and nanohardness of nanostructured TiAlN coating under N+ ion irradiation, Surface and Coatings Technology (2022). DOI: 10.1016/j.surfcoat.2022.128494