A new study from the University of Alberta is getting closer to making chicken feathers a good filter for cleaning water.

The ability of keratin from feathers to adsorb—or stick to—heavy metals typically found in the surface, well, or dugout water used by poultry producers for their stock has been improved through experiments utilizing two chemical agents.

Muhammad Zubair, who carried out the research in order to earn a Ph.D. in bioresource technology from the Faculty of Agricultural, Life, and Environmental Sciences, states that the study demonstrates that the bio-based filter is able to remove up to 99 percent of eight heavy metals simultaneously for the first time—the highest numbers that have been achieved thus far.

He asserts that this finding enhances the throwaway poultry byproduct’s potential as a sustainable, low-cost solution to a larger global issue.

“While having access to safe drinking water is essential for creating a society that is both healthy and long-lasting, many nations, like South Asia, have groundwater that is tainted with heavy metals. In 70 countries, arsenic has affected 137 million people alone.

Zubair’s work contributes to ongoing research into bio-based sorbents, which is led by Ullah through the University of Alberta’s Future Energy Systems program. Zubair is supervised by professors Aman Ullah and Roopesh Syamaladevi Mohandas.

Muhammad Zubair (left) and Aman Ullah hold samples of two improved materials for removing wastewater. These materials were created by chemically altering the keratin that is found in chicken feathers. Credit: University of Alberta.

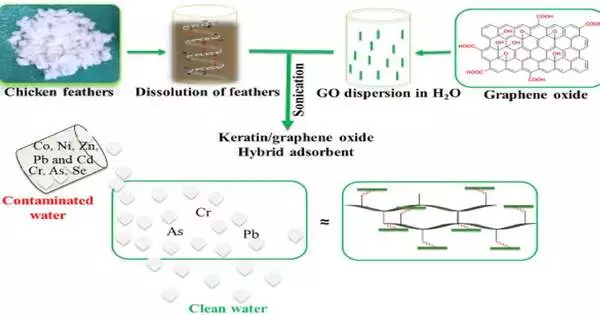

“An exciting step forward” from the University of Alberta Zubair altered the keratin’s properties with graphene oxide and nanochitosan in separate experiments to aid in the improvement of feather protein adsorption. The adsorbent, which appears to be a black powder, gained additional surface area as a result of the chemical treatment of the feathers.

Both synthetic specialists demonstrated powerful abilities at eliminating arsenic, cadmium, chromium, cobalt, lead, nickel, selenium, and zinc from little examples of reenacted wastewater, as Zubair’s examination showed.

Additionally, wastewater utilized in oil, gas, and mining processing commonly contains toxins. He adds that increasing the adsorbent’s capacity “is an exciting step forward for greater efficiency.”

He adds, “Working with the two chemicals also helped us better understand how keratin and heavy metals interact during adsorption.” That may assist us in modifying the properties of the keratin further and adsorbing additional heavy metals beyond the eight we worked with.”

Even though the adsorbent technology was only tested in simulated synthetic water for poultry use, he suggests that it could also be used in wastewater from oil and gas processing and other chemical-related industries. Potential for global impact

“This technology could impact the entire world and go beyond Alberta.”

As part of the process to eventually bring the chemically treated keratin to an industrial scale, it will now be tested in larger quantities of wastewater.

The examination is distributed in the journal Chemosphere.

More information: Muhammad Zubair et al, Nano-modified feather keratin derived green and sustainable biosorbents for the remediation of heavy metals from synthetic wastewater, Chemosphere (2022). DOI: 10.1016/j.chemosphere.2022.136339