As a component of NASA’s Artemis program to lay out a drawn-out presence on the moon, it plans to construct an Artemis headquarters that incorporates a cutting-edge lunar lodge, meanderer, and trailer. This decent territory might actually be developed with blocks made of lunar regolith and saltwater, on account of a new disclosure from a group of UCF scientists.

Academic partner Ranajay Ghosh of UCF’s Division of Mechanical and Advanced Plane Design and his exploration team tracked down that 3D-printed blocks of lunar regolith can endure the outrageous conditions of space and are a decent contender for enormous development projects. The free residue of rocks and materials that cover the moon’s surface is known as lunar regolith.

“BJT is particularly well suited to the melting of ceramic-like materials that are difficult to melt using a laser. As a result, regolith-based interplanetary manufacturing offers enormous potential for producing parts, components, and construction structures in a sustainable manner.”

Associate Professor Ranajay Ghosh of UCF’s Department of Mechanical and Aerospace Engineering

The consequences of their trials are nitty-gritty in a new issue of Earthenware Production Global.

To make the blocks, Ghosh’s group in the Perplexing Designs and Mechanics of Solids (Universe) Lab utilized a blend of 3D printing and folio fly innovation (BJT), an added substance producing technique that powers out a fluid restricting specialist onto a bed of powder. In Ghosh’s tests, the limiting specialist was saltwater, and the powder was regolith made by UCF’s Exolith Lab.

UCF Mechanical and Aeronautic Design Academic Administrator Ranajay Ghosh and graduate examination colleague Peter Warren make sense of the cycle they used to make round and hollow blocks utilizing reproduced lunar and Martian regolith. Credit: Focal Florida College

“BJT is extraordinarily reasonable for ceramic-like materials that are challenging to liquefy with a laser,” Ghosh says. “In this manner, it has extraordinary potential for regolith-based extraterrestrial assembling in a manageable manner to create parts, parts and development structures.”

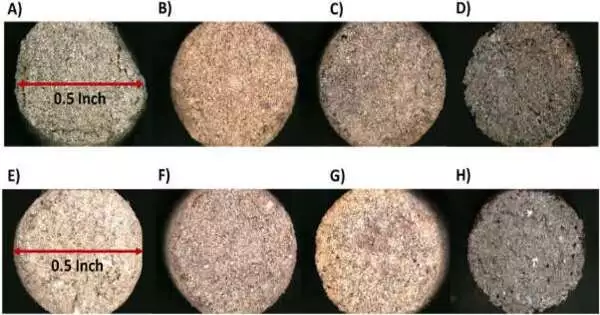

The BJT cycle brought about feeble tube-shaped blocks called “green parts” that were then prepared at high temperatures to create a more grounded structure. Blocks prepared at lower temperatures disintegrated, yet those presented to an intensity of up to 1200 degrees Celsius had the option to endure a strain of up to 250 million times the world’s environment.

Ghosh says the work clears the way for the utilization of BJT in the development of materials and designs in space. Their discoveries additionally show the way that off-world designs can be constructed utilizing assets found in space, which can definitely diminish the need to ship building materials for missions like Artemis.

“This examination adds to the continuous discussion in space investigation local area on finding the harmony between in-situ extraterrestrial asset use versus material shipped from Earth,” Ghosh says. “The further we foster methods that use the overflow of regolith, the greater capacity we will have in laying out and growing headquarters on the moon, Mars, and different planets later on.”

More information: Peter Warren et al, Effect of sintering temperature on microstructure and mechanical properties of molded Martian and Lunar regolith, Ceramics International (2022). DOI: 10.1016/j.ceramint.2022.07.329