Designers can now catch and foresee the strength of metallic materials exposed to cycling stacking, or weakness strength, very quickly — not the months or years it takes utilizing current techniques.

In another review, analysts from the College of Illinois Urbana-Champaign report that robotized high-goal electron imaging can catch the nanoscale twisting occasions that lead to metal disappointment and breakage at the beginning of metal disappointment. The new strategy assists researchers with quickly anticipating the weakness and strength of any amalgam and planning new materials for designing frameworks subject to continued stacking for clinical, transportation, security, energy, and natural applications.

The discoveries of the review, driven by materials science and design teachers Jean-Charles Stinville and Marie Charpagne, are distributed in the journal Science.

“This multiscale issue has been a long-standing concern since we’re trying to monitor sparse, nanometer-sized events that impact macroscopic features and can only be caught by probing huge areas with fine resolution,” says the researcher.

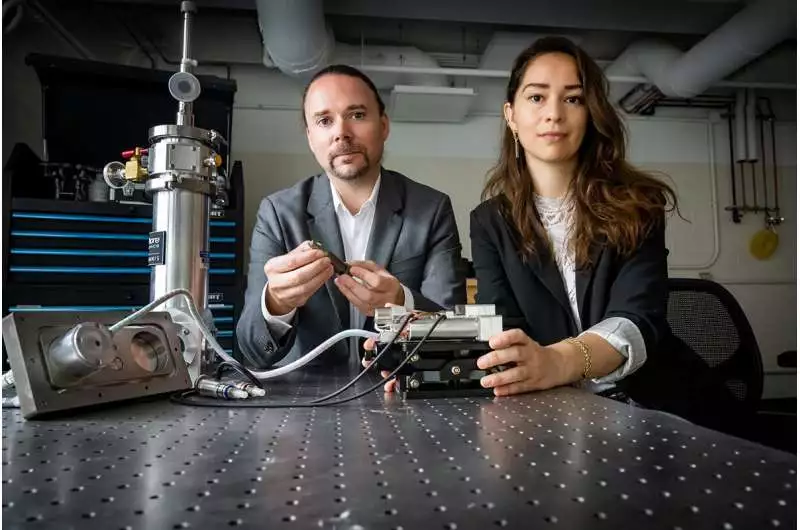

Engineering professors Jean-Charles Stinville and Marie Charpagne,

The weakness of metals and compounds — like the continued bowing of a metal paperclip that prompts its crack — is the main driver of disappointment in many design frameworks, Stinville said. Identifying the connection between weak strength and the microstructure is testing since metallic materials show complex designs with highlights going from the nanometer to the centimeter scale.

Materials science and design teachers Jean-Charles Stinville and Marie Charpagne caught the uncommon nanoscale twisting occasions at the beginning of metal disappointment that can assist analysts with planning new materials for clinical, transportation, security, energy, and environmental applications. Photographer: Fred Zwicky

“This multiscale issue is a well established issue since we’re attempting to notice scanty, nanometer-sized events that control perceptible properties and can be caught simply by examining huge regions with a fine goal,” Charpagne said. “The ongoing strategy for deciding weakness and strength in metals utilizes customary mechanical testing that is expensive, tedious, and doesn’t give a reasonable image of the main driver of disappointment.”

In the flow study, the analysts tracked down that the factual examination of the nanoscale events that show up at the metal surface when twisted can advise weakness or strength regarding metals. The group is quick to reveal this relationship utilizing robotized high-goal computerized picture connections gathered in the checking electron microscope — a method that orders and looks at a progression of pictures recorded during twisting, Stinville said. The scientists showed this connection to compounds of aluminum, cobalt, copper, iron, nickel, steel and stubborn composites utilized in a huge assortment of key design applications.

“What is striking is that the nanoscale twisting occasions that show up after a solitary deformity cycle relate to the weakness strengths that educate the life regarding a metallic part under countless cycles,” Stinville said. “Finding this connection resembles approaching a novel, twisting, unique mark that can assist us with quickly foreseeing the weakness life of metallic parts.”

“Planning metallic materials with higher weak strength implies more secure, stronger, and tougher materials,” Charpagne said. “This work has cultural, natural, and monetary effects since it reveals insight into the miniature and nanoscale boundaries to tune to materials with a more extended life. I figure this work will characterize another worldview in the amalgam plan.

More information: J. C. Stinville et al, On the origins of fatigue strength in crystalline metallic materials, Science (2022). DOI: 10.1126/science.abn0392

Journal information: Science