Researchers from Nanyang Mechanical College in Singapore (NTU Singapore) have developed a method for converting waste paper from single-use packaging and packs, as well as cardboard boxes, into an essential component of lithium-ion batteries.

Through an interaction called carbonization, which converts paper into unadulterated carbon, the NTU specialists transformed the paper’s filaments into cathodes, which can be made into battery-powered batteries that power cell phones, clinical gear, and electric vehicles.

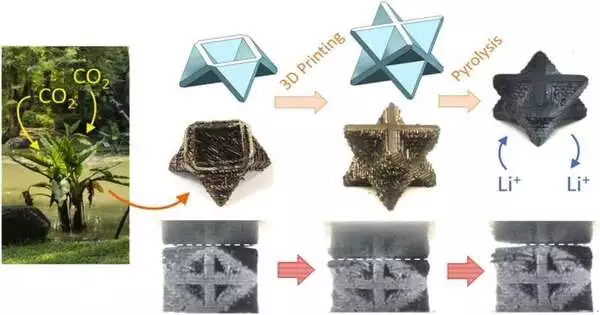

To carbonize the paper, the group exposed it to high temperatures, which diminished it to unadulterated carbon, water fumes, and oils that could be utilized for biofuel. As carbonization happens without a trace of oxygen, this emanates immaterial measures of carbon dioxide, and the interaction is a greener option in contrast to discarding kraft paper through cremation, delivering a lot of nursery gasses.

“Our way of reusing kraft paper by channeling it into the expanding demand for technologies like electric automobiles and smartphones would not only help reduce carbon emissions but would also reduce reliance on mining and heavy industrial methods.”

Mr Lim Guo Yao, a research engineer from NTU’s School of Mechanical & Aerospace Engineering,

The carbon anodes created by the exploration group likewise showed prevalent sturdiness, adaptability, and electrochemical properties. Research facility tests demonstrated the way that the anodes could be energized and released multiple times, which is somewhere around two times as sturdy as the anodes in flow telephone batteries. Batteries that use NTU-made anodes can also withstand more actual pressure than their competitors, engrossing pounding energy up to multiple times better.

The NTU-created strategy likewise utilizes less energy-intensive cycles and heavier metals compared with current modern techniques for assembling battery anodes. As the anode is worth 10% to 15% of the all-in cost of a lithium-particle battery, this most recent strategy, which utilizes minimally expensive waste material, is supposed to likewise cut down on the expense of assembling them.

The discoveries were distributed in the diary “Added Substance Assembling” in October.

Involving waste paper as the unrefined substance to create battery anodes would likewise facilitate our dependence on ordinary hotspots for carbon, for example, carbonaceous fillers and carbon-yielding covers, which are mined and later handled with brutal synthetics and apparatus.

Teacher Lai Changquan of NTU’s School of Mechanical and Aeronautic Design was the lead researcher who developed the strategy for making anodes out of waste paper.

Paper squander, which contains arranged paper sacks, cardboard, paper, and other paper bundling, represented almost a fifth of the waste created in Singapore in 2020.

Kraft paper sacks, which account for the majority of Singapore’s paper waste, were also discovered to have significant natural impressions when compared to their cotton and plastic counterparts, because of their greater commitment to an Earth-wide temperature rise when burned and the eco-poisonousness potential in delivering them, a different 2020 NTU focus.

The ongoing development, which presents an open door to upcycle byproducts and decrease our reliance on petroleum derivatives while speeding up our change towards a round economy, green materials, and clean energy, mirrors NTU’s obligation to relieve our effect on the climate, which is one of four great difficulties that the College tries to address through its NTU 2025 masterful course of action.

Partner Teacher Lai Changquan, from NTU’s School of Mechanical and Aeronautic Design, who drove the venture, said, “Paper is utilized in numerous features in our regular routines, from gift wrapping and expressions and specialties to a heap of modern purposes, like uncompromising bundling, defensive wrapping, and making up for shortfalls in development. Notwithstanding, little is done to oversee it when it is discarded, other than cremation, which creates elevated levels of fossil fuel byproducts because of its structure.

“Our strategy to reintroduce kraft paper into the growing demand for gadgets like electric vehicles and cell phones would not only help to eliminate fossil fuel byproducts, but would also help to reduce reliance on mining and heavy modern techniques.”

The exploration group has petitioned for a patent with NTUitive, NTU’s development and endeavor organization. They are additionally making progress toward commercializing their development.

The recipe for greener battery parts

To deliver the carbon anodes, the NTU scientists joined forces and laser-cut a few sheets of kraft paper to shape different cross-section calculations, some looking like a spikey piata. The paper was then warmed to 1200 °C in a heater without the presence of oxygen to change it into carbon, forming the anodes.

The NTU group ascribes the anode’s unrivaled sturdiness, adaptability, and electrochemical properties to the course of action of the paper strands. They said the blend of solidarity and mechanical durability shown by the NTU-made anodes would permit batteries in telephones, workstations, and cars to all the more likely endure shocks from falls and crashes.

Flow lithium battery innovation depends on inner carbon anodes that slowly break and disintegrate after actual shocks from being dropped, which is one of the principal motivations behind why battery duration gets more limited with time.

The specialists say that their anodes, which are harder than flow terminals utilized in batteries, would assist with resolving this issue and broaden the use of batteries for a wide range of purposes, from hardware to electric vehicles.

The co-creator of the review, Mr. Lim Guo Yao, an exploration engineer from NTU’s School of Mechanical and Aeronautic Design, said, “Our anodes showed a mix of qualities, for example, strength, shock retention, and electrical conductivity, which are not tracked down in flow materials.” These primary and utilitarian properties show that our kraft paper-based anodes are a reasonable and versatile option in contrast to current carbon materials and would track down monetary worth in requesting top-of-the-line, multifunctional applications, like the early field of underlying batteries.

Asst. Prof. Lai added, “Our strategy changes over a typical and omnipresent material—ppaper—to another that is very sturdy and popular.” “We trust that our anodes will serve the world’s rapidly developing requirement for a reasonable and greener material for batteries, whose assembly and ill-advised squandering by executives adversely affect our current circumstance.”

Featuring the meaning of the work done by the NTU research group, Teacher Juan Hinestroza from the Division of Human Focused Planning at Cornell College, who was not engaged with the exploration, said, “As kraft paper is delivered in exceptionally huge amounts and arranged similarly everywhere, I accept that the imaginative methodology spearheaded by the specialists at NTU Singapore has an extraordinary potential for influence at a worldwide scale.”

“Any revelation that will enable the utilization of waste as a natural substance for high-value items like cathodes and froths is unquestionably a fantastic commitment.”I believe that this work will pave the way for other scientists to find ways to change other cellulose-based substrates, such as materials and bundling materials, which are being discarded in massive quantities all over the world.

The NTU group will lead further exploration to further develop the energy stockpiling limit of their material and limit the intensity of energy expected to change the paper into carbon.

More information: Chang Quan Lai et al, Exceptional energy absorption characteristics and compressive resilience of functional carbon foams scalably and sustainably derived from additively manufactured kraft paper, Additive Manufacturing (2022). DOI: 10.1016/j.addma.2022.102992