Robots, in light of delicate materials, are in many cases better at recreating the appearance, developments, and capacities of people and creatures. While there are presently innumerable delicate robots, a significant number of them are hard to deliver because of the significant expense of their parts or their intricate creation process.

Scientists at the College of Coimbra in Portugal have as of late fostered another delicate mechanical hand that could be more reasonable and simpler to manufacture. Their plan, presented in cyborg and bionic frameworks, coordinates delicate actuators with an exoskeleton, the two of which can be delivered using versatile procedures.

“Most robots are made of inflexible materials,” Pedro Neto, one of the scientists who did the review, told Tech Xplore. “In any case, when we notice creatures, we notice that their bodies can be made out of hard aspects (skeletons) and delicate parts (like muscles). A few creatures, similar to worms, are completely delicate-bodied. Taking motivation from nature, we guess that the up and coming age of robots will consolidate parts made of delicate materials or, at times, they can be totally delicate bodies.”

“The majority of robots are composed of stiff materials. When we watch animals, we see that their bodies might be made up of both hard (skeletons) and soft (muscles). Some species, such as earthworms, have completely squishy bodies. Taking inspiration from nature, we believe that the future generation of robots will have soft-bodied components or, in certain situations, be totally soft-bodied.”

Pedro Neto, one of the researchers who carried out the study,

Contrasted with unbending robots, delicate mechanical frameworks could be more secure and could better coincide with people or creatures in both outside and indoor conditions. For example, in the event that they crash into people, creatures, or articles in their environment, these robots are less inclined to cause critical harm or wounds.

The vital goal of the new work by Neto and his partners was to foster another delicate mechanical hand that is both protected and reasonable. Such a hand would hypothetically be more straightforward to send for an enormous scope, consequently energizing new exploration and development in the field of mechanical technology.

“We utilized limited component examination to upgrade the plan before truly manufacturing the hand, lessening prototyping costs,” Neto made sense of. “The usage of customary 3D printing was demonstrated viable by straightforwardly printing a few parts in delicate materials and printing molds in unbending materials.”

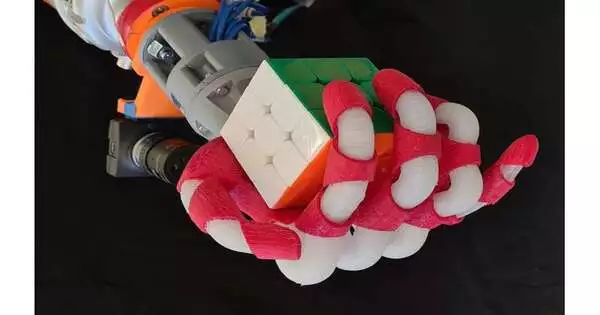

The delicate mechanical hand made by Neto and his associates depends on a few unique materials. Its painstakingly planned structure was intended to duplicate the appearance and usefulness of human hands, imitating their developments and capacities.

“The mechanical hand’s design comprises five delicate actuators, each compared to a finger, and an exoskeleton to advance the finger’s bendability,” Neto said. “An ON-OFF regulator keeps up with the predetermined finger bowing points, empowering the hand to successfully grasp objects of shifting shapes, loads, and aspects.”

The scientists up until this point assessed the presentation of their mechanical hand in a progression of reenactments and examinations. Their underlying outcomes are exceptionally encouraging, as the hand could effectively get a handle on various items of various shapes, weights, and sizes.

“The essential commitment is the coordinated plan creation framework that uses limited component investigation to advance the plan before its manufacture,” Neto said. “This accomplishment can possibly build the availability of delicate mechanical hands while bringing down costs and wiping out the normally tedious plan creation methodology, which regularly depends on asset-concentrated iterative work processes.”

Credit: Alves et al.

Later on, the delicate mechanical hand created by this group of scientists could be utilized by both scholarly groups and individual roboticists to test new computerized reasoning (man-made intelligence) calculations and other computational apparatuses pointed toward propelling robot capacities. Moreover, its plan could open new roads for the minimally expensive manufacture of humanoid robots that can help people with their regular exercises.

“Our next investigations will zero in on working on the manufacture of delicate actuators and sensors, expecting to improve the openness of delicate robots to a more extensive crowd,” Neto added. “The control of delicate robots utilizing man-made brainpower is one more exploration point that we are chipping away at.”

More information: Samuel Alves et al, Integrated Design Fabrication and Control of a Bioinspired Multimaterial Soft Robotic Hand, Cyborg and Bionic Systems (2023). DOI: 10.34133/cbsystems.0051