A group of specialists from the ITACA Establishment of the Universitat Politècnica de València (UPV) and the Exploration Organization of Synthetic Innovation, a joint focal point of the Spanish Public Exploration Board (CSIC) and the UPV, has found another strategy for the production of metal nanocatalysts that is more practical and efficient.

With extraordinary likelihood in the modern area, the technique would add to the decarbonization of industry. The work has been distributed in the journal ACS Nano.

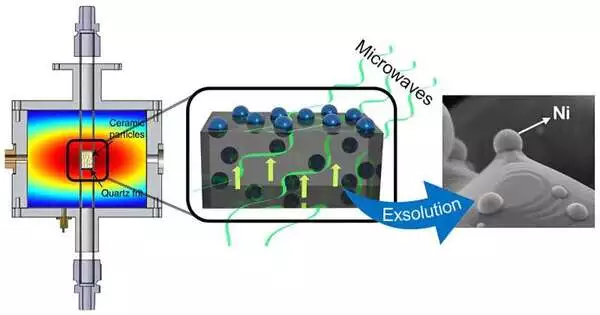

This new technique depends on the exsolution interaction enacted by microwave radiation. Exsolution is a technique for producing metallic nanoparticles on the outer layer of earthenware materials. “At raised temperatures and in a diminishing environment (typically hydrogen), metal molecules move from the construction of the material to its surface, framing metal nanoparticles secured to the surface. This securing essentially expands the strength and steadiness of these nanoparticles, which emphatically influences the proficiency of these impetuses,” makes sense of Beatriz García Baños, a scientist in the Microwave Region of the ITACA Organization at the UPV.

“At high temperatures and in a reducing atmosphere (usually hydrogen), metal atoms migrate from the material’s structure to its surface, forming metal nanoparticles that are anchored to the surface. This anchoring considerably boosts the strength and stability of these nanoparticles, which improves the efficiency of these catalysts.”

Beatriz García Baños, a researcher in the Microwave Area of the ITACA Institute at the UPV.

In the review, the UPV and CSIC specialists have shown that, on account of microwave radiation, this cycle can be completed at additional moderate temperatures without the need to utilize lessening air.

“Along these lines, dynamic nickel nanocatalysts can be delivered in a more energy-efficient exsolution process. These impetuses have been shown to be dynamic and stable for the response of CO creation from CO2, getting a result of modern interest and adding to the decarbonization of the area,” says Alfonso Juan Carrillo Del Teso, specialist of the Energy Transformation and Capacity Gathering of the ITQ.

The exsolution cycle exhibited in nickel nanoparticles has been completed at temperatures of around 400 ºC and openness seasons of a couple of moments, though the ordinary exsolution system in these materials happens at temperatures of 900 ºC with seasons of around 10 hours. Also, this innovation permits exsolution to be performed without utilizing hydrogen.

“For a large number of reasons, we work on the manageability of the cycle. Besides, by getting the impetuses at milder temperatures and more limited openness times, we lessen the expenses of the cycle, which is likewise impacted by not involving hydrogen as a diminishing gas,” adds Beatriz García Baños.

Applications

The interaction created by the UPV and CSIC groups is basically expected for high-temperature synergist techniques for putting away and changing over sustainable power. It could likewise be applied to improving biogas responses for the creation of amalgamation gas (antecedent of fluid energizers), CO2 hydrogenation responses relevant to capacity-to-X frameworks, and functionalizing terminals for energy units as well as high-temperature electrolyzers.

More information: Andrés López-García et al, Microwave-Driven Exsolution of Ni Nanoparticles in A-Site Deficient Perovskites, ACS Nano (2023). DOI: 10.1021/acsnano.3c08534