Researchers from Nanyang Technological University, Singapore (NTU Singapore) have figured out how to make biocement from squander, making the option, in contrast to ordinary concrete, considerably greener and more economical.

Biocement is a sustainable type of concrete that commonly utilizes microorganisms to frame a solidifying response that ties soil into a strong square.

The NTU researchers have now figured out how to utilize two normal waste materials, modern carbide ooze and urea—from the pee of warm-blooded animals—to make biocement.

They facilitated a cycle in which the reaction of urea with calcium particles in modern carbide slime shapes a hard, strong, or encouraging structure.At the point when this response happens in soil, the accelerator secures soil particles together and fills the holes between them, making a minimized mass of soil. This results in a solid, tough and less porous square of biocement.

The exploration group, led by Professor Chu Jian, Chair of the School of Civil and Environmental Engineering, demonstrated in a proof-of-idea research paper distributed in February 2022 in the Journal of Environmental Chemical Engineering that their biocement might actually turn into an economical and financially savvy technique for soil improvement, like reinforcing the ground for use in development or exhuming, controlling ocean side disintegration, diminishing residue or wind disintegration in the desert, or building freshwater supplies on sea shores or in the desert.

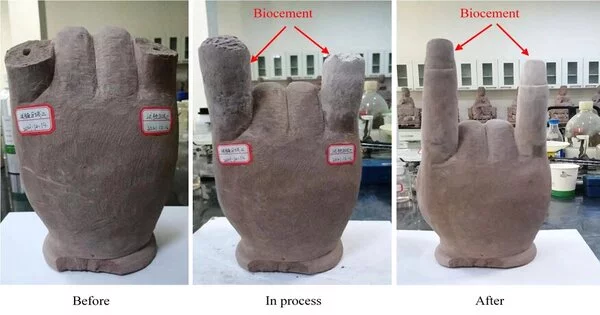

It can likewise be used as biogrout to seal breaks in rock for leakage control and even to finish up and fix landmarks like stone carvings and sculptures.

“Biocement is an economical and inexhaustible option in contrast to conventional concrete and can possibly be utilized for development projects that require the ground to be dealt with,” said Prof. Chu, who is likewise the Director of NTU’s Center for Urban Solutions. “Our exploration makes biocement considerably more maintainable by involving two kinds of waste material as its unrefined substances.” “Over the long haul, it won’t just make it less expensive to produce biocement, but additionally diminish the expense required for garbage removal.”

The NTU researchers’ exploration upholds the NTU 2025 well-thought out plan, which intends to address a portion of mankind’s great difficulties, remembering to moderate human effect on the climate through promoting innovative work in manageability.

Pee, microorganisms, and calcium: a basic recipe for biocement

The biocement-production process requires less energy and creates fewer fossil fuel byproducts compared with customary concrete creation techniques.

The NTU group’s biocement is made from two sorts of waste material: modern carbide ooze—the waste material from the development of acetylene gas, obtained from Singapore production lines—and urea found in pee.

Right off the bat, the group treats carbide muck with a corrosive to deliver dissolvable calcium. Urea is then added to the solvent calcium to frame a cementation arrangement. The group then adds a bacterial culture to this cementation arrangement. The microorganisms from the way of life then, at that point, separate the urea in the answer into carbonate particles.

“Biocement is a sustainable and renewable alternative to traditional cement and has great potential to be used for construction projects that require the ground to be treated,”

Prof Chu, Director of NTU’s Center for Urban Solutions.

These particles respond to the dissolvable calcium particles in an interaction called microbially instigated calcite precipitation (MICP). This response structures calcium carbonate—a hard, strong material that is normally found in chalk, limestone, and marble.

When this response happens in soil or sand, the subsequent calcium carbonate produced bonds soil or sand particles together to build their solidarity and fills the pores between them to lessen water drainage through the material. A similar interaction can likewise be utilized on rock joints, which takes into account the maintenance of rock carvings and sculptures.

The dirt built up with biocement has an unconfined pressure strength of up to 1.7 megapascals (MPa), which is higher than that of a similar soil treated by utilizing a comparable measure of concrete.

This makes the group’s biocement reasonable for use in soil improvement tasks like fortifying the ground or lessening water drainage for use in development or uncovering or controlling oceanside disintegration along shores.

Dr. Yang, a previous NTU Ph.D. understudy and exploration partner at the Center for Urban Solutions who is right now a postdoctoral individual at Chongqing University, China, said: “The calcium carbonate precipitation at different cementation levels reinforces the dirt or sand bit by bit, finishing up the pores among the particles.” The biocement could likewise be utilized to seal breaks in soil or shake to lessen water leakage. “

A low-cost option for strengthening

Biocement creation is greener and more reasonable than the techniques used to deliver conventional concrete.

“One piece of the concrete making process is the consumption of unrefined substances at exceptionally high temperatures north of 1,000 degrees Celsius to shape clinkers—the limiting specialist for concrete. This interaction creates a great deal of carbon dioxide, “said Prof. Chu. “In any case, our biocement is created at room temperature without consuming anything, and in this way it is a greener, less energy-requesting, and carbon-impartial interaction.”

Dr. Yang said: “In Singapore, carbide muck is viewed as waste material. Nonetheless, it is a decent unrefined substance for the development of biocement. By separating calcium from carbide slime, we make the creation more economical as we don’t have to utilize materials like limestone, which must be mined from a mountain. “

Prof Chu added: “Limestone is a limited asset—whenever it’s gone, it’s gone.” The mining of limestone influences our common habitat and environment as well. “

The exploration group says that if biocement creation could be scaled to the degree of customary concrete making, the general expense of its creation compared with that of traditional concrete would be lower, which would make biocement both a greener and less expensive choice to solidify.

Reestablishing landmarks and fortifying coastlines

One more benefit of the NTU group’s technique in figuring out biocement is that both the bacterial culture and cementation arrangement are lackluster. When applied to soil, sand, or rock, their unique tones are preserved.

This makes it valuable for renovating old stone landmarks and antiques. For instance, Dr. Yang has used biocement to fix old Buddha landmarks in China. The biocement can be utilized to seal holes in broken landmarks and has been utilized to reestablish severed pieces, like the fingers of a Buddha’s hands. While the arrangement is lackluster, the landmarks hold their unique tone, keeping the reclamation work consistent with history.

In a joint effort with important public organizations in Singapore, the group is as of now testing their new biocement at East Coast Park, where it is being utilized to reinforce the sand on the ocean front. By splashing the biocement arrangements on top of the sand, a hard covering is shaped, keeping sand from being cleaned out to the ocean.

The group is also investigating additional broad range applications of their biocement in Singapore, for example, street fixing by repairing breaks in streets, repairing holes in underground passages to prevent water drainage, or even as a development reason for coral reefs because ditty hatchlings like to develop on calcium carbonate.

The paper, “Usage of carbide muck and pee for feasible biocement creation,” is published in the Journal of Environmental Chemical Engineering.