Natural sun-based cells (OSCs), which utilize natural materials to change daylight into power, are an alluring contender for future photovoltaics. This is because of a few of their helpful elements, like their light weight, adaptability, pliability, and, in particular, high power change proficiency (PCE). Such characteristics make them ideal for many applications.

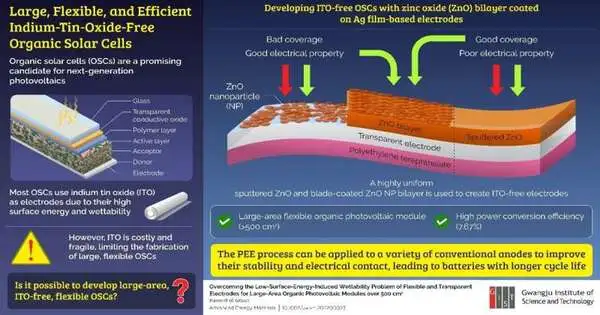

In spite of their huge commercialization potential, in any case, there is a trick. Most OSCs are created utilizing a method called “turn covering,” which considers high PCEs yet makes for unfortunate versatility. Also, OSCs with adaptable anodes use indium tin oxide (ITO), which makes them costly and excessively delicate for acknowledging huge region modules. Hence, assuming the business commitment of OSCs is to be understood, they should eliminate their reliance on ITO.

This is where Dr. Hongkyu Kang and Prof. Kwanghee Lee from the Gwangju Institute of Science and Technology (GIST) in Korea come in. In their paper in Advanced Energy Materials, they set forth another strategy to make OSCs utilizing zinc oxide (ZnO) that defeats the issues of cost and versatility without containing the PCE.

Specifically, this examination was the aftereffect of an industry-college joint effort in which GIST fostered the first innovation without precedent for Korea and moved it to MSWAY Co., Ltd., which had been altogether subject to imported products as the homegrown creation of ITO-based cathodes was unfeasible. With the new innovation, it is normal that a value chain will be laid out for the commercialization of OSCs with development and gear organizations, reinforcing the value of industry-college joint examination.

“The ultrathin silver film electrode with ZnO bilayer offers the flexibility, wettability, and high surface energy of ITO while being less brittle and less costly. This simplifies the use of ZnO in the production of organic solar cells and the development of a printing technology for large-area solar cell technology.”

Dr. Hongkyu Kang

The group utilized faltered ZnO and a ZnO nanoparticle layer made through an “edge covering” method to make a uniform bilayer on an ultrathin silver film cathode. “The ultrathin silver film anode with ZnO bilayer has the adaptability, wettability, and high surface energy of ITO yet isn’t weak or costly.” This makes it simpler to involve ZnO for assembling natural sun-based cells and fostering a printing innovation for huge regions of sun-powered cell innovation, “says Dr. Kang.

The new ZnO bilayer-based OSCs showed a proficiency of 7.67% for a module area of 528 cm2, which makes it the most effective large-region OSC when compared with past exploration. This was because of the decrease in “recombination” of charge transporters in OSCs by the glasslike ZnO nanoparticles that, thus, further developed their open-circuit voltage, i.e., PCE.

The making of these sans ito OSCs with a huge region and the same adaptability and proficiency as that of ITO-based OSCs can be a unique advantage for the fate of solar power cell innovation. “Our strategy opens ways to the business utilization of these OSCs, like their mix into building walls and windows to create self-supporting structures,” says Prof. Lee. Without a doubt, the prevalence of large regional OSCs in terms of business potential and proficiency can usher in a new age of force and aid us in our fight against environmental evolution.

More information: Hyeok‐Chan Kwon et al, Overcoming the Low‐Surface‐Energy‐Induced Wettability Problem of Flexible and Transparent Electrodes for Large‐Area Organic Photovoltaic Modules over 500 cm 2, Advanced Energy Materials (2022). DOI: 10.1002/aenm.202200023

Journal information: Advanced Energy Materials