We frequently look to the littlest lifeforms for help tackling the most serious issues: Organisms assist with making food varieties and drinks, fix infections, treat waste, and, surprisingly, tidy up contamination. Yeast and microbes can likewise change plant sugars into biofuels and synthetic substances customarily derived from petroleum derivatives—a vital part of most designs to slow environmental change.

Presently, College of Wisconsin-Madison scientists have designed microbes that can deliver two synthetic items simultaneously from underutilized plant fiber. Furthermore, not at all like people, these microorganisms can do the two things similarly well.

“As far as anyone is concerned, it’s one of the main times you can make two important items all the while in one microorganism,” says Tim Donohue, UW-Madison teacher of bacteriology and head of the Incomparable Lakes Bioenergy Exploration Center.

“In general, the strategy reduces net greenhouse gas emissions while improving economics. The amount of energy and greenhouse gas required to create two products in one pot will be less than that required to run two pots to make one product in each pot.”

Tim Donohue, UW–Madison professor of bacteriology and director of the Great Lakes Bioenergy Research Center.

The disclosure, itemized in a paper in the journal Applied and Natural Microbial Science, could help make biofuels more economical and financially viable.

“On a basic level, the technique brings down the net ozone-harming substance outflows and works on financial matters,” Donohue says. “How much energy and ozone-harming substances do you really want to make two items in a single pot? You will not exactly run two pots to make one item in each pot.”

Each particle counts.

The mission to supplant non-renewable energy sources with economical options depends on extracting the most conceivable value from sustainable biomass. Similarly, with petrochemicals, each particle counts: Low-volume, high-esteem items assist with keeping fuel more reasonable.

One of the greatest hindrances is a piece of the plant cell wall called lignin. Lignin is the world’s most bountiful wellspring of sustainable fragrant carbons, yet its sporadic design makes it famously challenging to fall into pieces into helpful parts.

That is the reason researchers with GLBRC have concentrated on a bacterium named Novosphingobium aromaticivorans (at times alluded to as essentially Novo), which can process a large number of lignins and is moderately simple to change hereditarily.

In 2019, specialists designed a type of Novo that can deliver a critical element of plastics like nylon and polyurethane known as PDC. All the more, as of late, a group in Donohue’s lab found another change that permits Novo to make an alternate plastic fixing called ccMA.

Yet, they didn’t stop there.

“We won’t tackle our fossil fuel byproducts issue by just delivering two items,” says Ben Corridor, a new doctoral alumni who added to the exploration.

Ben Corridor, a hereditary qualities Ph.D. understudy, holds a blended example of microorganisms and carotenoids in Tim Donohue’s lab. Credit: Chelsea Mamott.

Donohue’s group utilized genomic displaying to concoct a rundown of potential items that could be produced using biomass aromatics. Close to the first spot on the list was zeaxanthin, one of a group of natural colors known as carotenoids.

Carotenoids, which give carrots, pumpkins, salmon, and even flamingos their unmistakable tints, are utilized as healthful enhancements, drugs, and beauty care products and have a total market value worth a huge number of dollars a year.

Specialists realize that Novo has the qualities to deliver one more carotenoid with little market value. In view of the microscopic organisms’ genome succession, they thought zeaxanthin was a venturing stone to that less important carotenoid in the process that phones use to make complex particles. It was simply an issue of changing the right qualities to stop the stomach-related sequential construction system at the more significant item.

By erasing or adding chosen qualities, they designed strains that created zeaxanthin as well as other important carotenoids—beta-carotene, lycopene, and astaxanthin—when developed on a sweet-smelling compound usually tracked down in lignin.

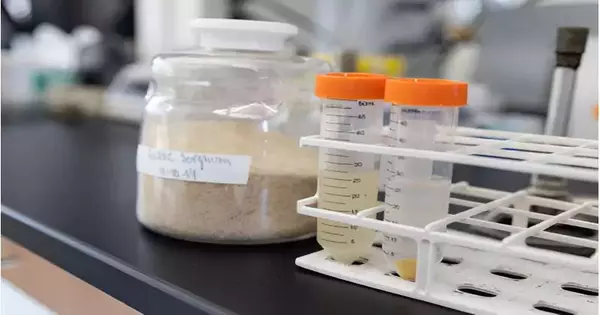

Then, the group demonstrated the way that the designed microorganisms could create similar carotenoids from an alcohol produced using ground and treated sorghum stems, an answer that contains a combination of aromatics that numerous modern microbes can’t process.

One pot, two items

Corridor then, at that point, considered what might occur assuming he joined the hereditary changes expected to make PDC and a carotenoid in a similar organism.

The subsequent strains delivered both PDC and the objective carotenoid, with no recognizable misfortune to one or the other yield. Far superior, the microbes aggregated carotenoids inside their cells, which should be isolated from the arrangement that contains the PDC, which they emitted.

“We’re isolating the cells from the media,” Lobby says. “Presently, we would have an item emerging from both.”

The subsequent stages incorporate testing whether designed strains can all the while produce carotenoids and ccMA, which Donohue figures they will, and designing strains to further develop yields in modern circumstances.

While there are rewarding business sectors for every one of these items, Donohue and Lobby say the genuine worth of the disclosure is the capacity to add different capabilities to this natural stage.

“As far as I’m concerned, it’s both the procedure and the items,” Donohue says. “Now that we’ve done this, I think it makes the way for us to check whether we can make other microbial skeletons that make two items.”

More information: Benjamin W. Hall et al. Production of carotenoids from aromatics and pretreated lignocellulosic biomass by Novosphingobium aromaticivorans, Applied and Environmental Microbiology (2023). DOI: 10.1128/aem.01268-23