The requirement for innovation that can catch, eliminate, and reuse carbon dioxide grows with each CO2 particle that arrives at Earth’s environment. To address that issue, researchers at the Division of Energy’s Pacific Northwest Public Lab have achieved another milestone in their endeavors to make carbon capture more reasonable and broad. They have made another framework that productively catches CO2—the least expensive to date—and changes it into one of the world’s most broadly utilized synthetic compounds: methanol.

Trapping CO2 before it floats into the climate is a vital part of easing back an unnatural weather change. Making incentives for the largest producers to pursue carbon capture innovation is a significant precursor.The significant expense of business catch innovation is a longstanding hindrance to its far and wide use.

PNNL researchers accept that methanol can provide that motivating force. It serves many purposes as a fuel, is dissolvable, and is a significant fixing agent in plastics, paint, development materials, and vehicle parts. Changing CO2 into helpful substances like methanol offers a way for modern elements to catch and reuse their carbon.

PNNL scientific expert David Heldebrant, who drives the exploration group behind the new innovation, looks at the framework for reusing. Similarly, just as one can choose between single-use and recyclable materials, one can reuse carbon at any time.

“That is basically the thing we’re attempting to do here,” said Heldebrant. “Rather than removing oil from the beginning to make these synthetics, we’re attempting to do it from CO2 caught from the environment or from coal plants, so it very well may be reconstituted into helpful things.” You’re keeping carbon alive, in a manner of speaking, so it’s not simply “haul it out of the ground, use it once, and discard it.” “We’re attempting to reuse the CO2, similar to how we attempt to reuse different things like glass, aluminum, and plastics.”

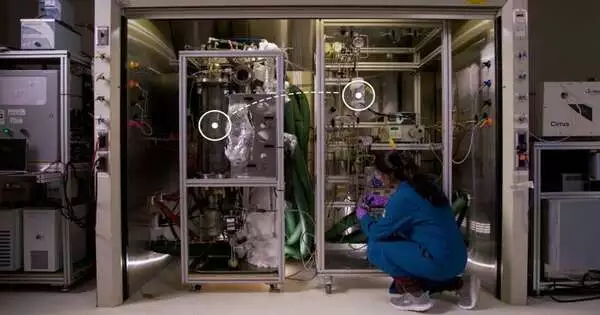

As depicted in the diary, “Progressed Energy Materials,” the new framework is intended to fit into coal-, gas-, or biomass-terminated power plants, as well as concrete ovens and steel plants. Utilizing a PNNL-created catch dissolvable, the framework grabs CO2 particles before they’re produced and, at that point, changes them over into helpful, sellable substances.

A long line of dominoes must fall before carbon can be totally taken out of or kept from entering Earth’s environment. This work—getting catch-and-change innovation out into the world—addresses a portion of the initial, not very urgent needs.

“Conveying this innovation will diminish emanations,” said Heldebrant. Yet, it could likewise assist with the improvement of other carbon capture innovations and lay out a business opportunity for CO2-containing materials. With such a market in place, carbon captured by anticipated direct air catch innovations could be better reconstituted into longer-lasting materials.

Researchers at the Pacific Northwest Public Lab have developed the most reasonable carbon dioxide catch and transformation framework to date, carrying the expense to catch CO2 down to about $39 per metric ton. The cycle takes pipe gas from power plants, utilizes a PNNL-protected dissolvable to strip out CO2, and then, at that point, changes over the CO2 into economically valuable methanol.

The call for less expensive carbon capture

In April 2022, the Intergovernmental Board on Environmental Change gave its Functioning Gathering III report, which zeroed in on relieving environmental change. Among the outflows restricting measures framed, carbon catch and capacity were named as a fundamental component in accomplishing net zero emissions, particularly in areas that are hard to decarbonize, similar to steel and synthetic creation.

“Reducing discharges in industry will include utilizing materials more productively, reusing and reusing items, and limiting waste,” the IPCC stated in a news release distributed alongside one of the report’s 2022 sections.”To arrive at net zero CO2 outflows for the carbon required in the public eye (e.g., plastics, wood, aeronautics fuels, solvents, etc.),” the report peruses, “it is vital to close the utilization circles for carbon and carbon dioxide through expanded circularity with mechanical and synthetic reusing.”

PNNL’s examination is centered around doing precisely that, in arrangement with DOE’s Carbon Negative Shot. By utilizing sustainably obtained hydrogen in the transformation, the group can create methanol with a lower carbon footprint than traditional techniques that utilize flammable gas as a feedstock. Methanol produced through CO2 transformation could meet all of the requirements for strategy and market motivations that are expected to drive acceptance of carbon dioxide reduction advances.

Methanol is among the most exceptionally created synthetic substances in terms of volume. Known as “stage material,” its purposes are colossal. Aside from methanol, the group can convert CO2 into formate (another item compound), methane, and other substances.

A lot of work remains to enhance and scale this cycle, and it could be quite a while before it is ready for business sending. However, according to Casie Davidson, director of PNNL’s Carbon Board and Fossil Energy Market Area, it is only now beginning to displace traditional substance products.”The group’s coordinated methodology opens up a universe of new CO2 transformation science.” There’s a feeling that we’re remaining on the edge of a totally new field of versatile, practical carbon technology. “It’s an exceptionally interesting time.”

Disintegrating costs

Business frameworks absorb carbon from vent gas at a rate of generally $46 per metric ton of CO2, as indicated by a DOE examination. The PNNL’s group will likely consistently work to reduce costs by making the catch cycle more productive and financially competitive.

The group brought the expense of the catch down to $47.10 per metric ton of CO2 in 2021. Another review depicted in the Diary of Cleaner Creation investigates the expense of running the methanol framework utilizing different PNNL-created catch solvents, and that figure has now dropped to simply beneath $39 per metric ton of CO2.

“We took a gander at three CO2-restricting solvents in this new review,” said synthetic designer Yuan Jiang, who drove the evaluation. “We found that they catch more than 90% of the carbon that goes through them, and they do as such for about 75% of the expense of conventional catch innovation.”

Depending on the plant or furnace concept, various frameworks can be used.However, regardless of the arrangement, solvents are the focal point. In these frameworks, solvents wash over CO2-rich pipe gas before it’s discharged, abandoning CO2 particles presently bound inside that fluid.

Making methanol from CO2 isn’t new. In any case, the capacity to both catch carbon and afterward convert it into methanol in one ceaselessly streaming framework Catch-and-transformation has generally happened as two particular advances, isolated by each interaction’s interesting, frequently non-correlative science.

“We’re at long last ensuring that one innovation can do the two stages and do them effectively,” said Heldebrant, adding that conventional change innovation normally requires profoundly decontaminated CO2. The new framework makes it quick to make methanol from “grimy” CO2.

Dialing down the upcoming discharges

The most common way of catching CO2 and changing it completely over to methanol isn’t CO2-negative. Methanol’s carbon is delivered when it is consumed or sequestered when it is completely converted to substances with longer life expectancies. Be that as it may, this innovation does “set the stage,” Heldebrant said, for the significant work of keeping carbon bound inside materials and out of the air.

Other objective materials incorporate polyurethanes, which are tracked down in cements, coatings, and foam protection, and polyesters, which are broadly utilized in textures for materials. When scientists have completed the science of converting CO2 into materials that keep it out of the environment for environmentally relevant timescales, a wide range of catch frameworks may be ready to run such responses.

In lieu of the present smokestacks, Heldebrant imagines CO2 treatment facilities incorporated into or close to power plants, where CO2-containing items can be made nearby. “We are at a defining moment,” Heldebrant and his coauthors wrote in a new article distributed in the journal Synthetic Science, “where we can keep on utilizing the twentieth century’s solid catch and change framework or we can start the progress to another 21st century worldview of coordinated dissolvable-based carbon catch and transformation advancements.”

More information: Jotheeswari Kothandaraman et al, Integrated Capture and Conversion of CO 2 to Methanol in a Post‐Combustion Capture Solvent: Heterogeneous Catalysts for Selective CN Bond Cleavage, Advanced Energy Materials (2022). DOI: 10.1002/aenm.202202369

Yuan Jiang et al, Energy-effective and low-cost carbon capture from point-sources enabled by water-lean solvents, Journal of Cleaner Production (2022). DOI: 10.1016/j.jclepro.2022.135696