Catalysis is a process in which a catalyst, a substance that speeds up a chemical reaction without being consumed itself, is used to increase the efficiency of chemical reactions. This can lead to significant energy savings in various industries, including energy production, transportation, and manufacturing.

University of Wisconsin-Madison chemical engineers have developed a model of how catalytic reactions work at the atomic scale, which they consider a breakthrough in computational chemistry research. This understanding could enable engineers and chemists to create more efficient catalysts and tune industrial processes, potentially saving enormous amounts of energy, given that catalysis is responsible for the production of 90% of the products we encounter in our daily lives.

Catalyst materials speed up chemical reactions without changing themselves. They are essential in the refining of petroleum products as well as the production of pharmaceuticals, plastics, food additives, fertilizers, green fuels, industrial chemicals, and many other products.

The prevailing assumption is that these metal atoms are strongly bonded to each other and simply provide ‘landing spots’ for reactants. What everybody has assumed is that metal-metal bonds remain intact during the reactions they catalyze.

Manos Mavrikakis

Scientists and engineers have spent decades fine-tuning catalytic reactions, but because it is currently impossible to directly observe those reactions at the extreme temperatures and pressures commonly involved in industrial-scale catalysis, they do not know exactly what is happening on the nano and atomic scales. This new study contributes to the unraveling of that mystery, with potentially significant implications for industry.

In fact, only three catalytic reactions use close to 10% of the world’s energy: steam-methane reforming to produce hydrogen, ammonia synthesis to produce fertilizer, and methanol synthesis.

“If you decrease the temperatures at which you have to run these reactions by only a few degrees, there will be an enormous decrease in the energy demand that we face as humanity today,” says Manos Mavrikakis, a professor of chemical and biological engineering at UW-Madison who led the research. “By decreasing the energy needs to run all these processes, you are also decreasing their environmental footprint.”

Mavrikakis and postdoctoral researchers Lang Xu and Konstantinos G. Papanikolaou along with graduate student Lisa Je published news of their advance in the issue of the journal Science.

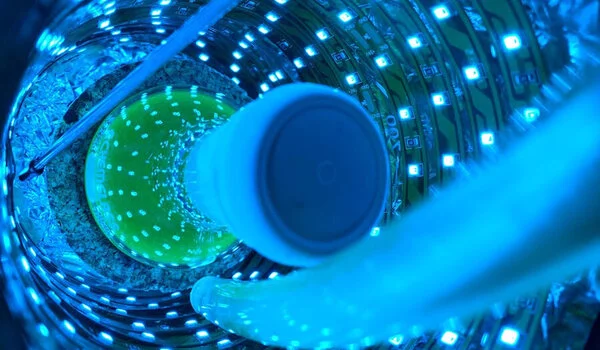

The UW-Madison engineers use powerful modeling techniques to simulate catalytic reactions at the atomic scale in their research. They examined reactions involving transition metal catalysts in nanoparticle form for this study, which included elements such as platinum, palladium, rhodium, copper, nickel, and others important in industry and green energy.

The tightly packed atoms of transition metal catalysts, according to the current rigid-surface model of catalysis, provide a 2D surface to which chemical reactants adhere and participate in reactions. When enough pressure, heat, or electricity is applied to the chemical reactants, the bonds between the atoms break, allowing the fragments to recombine into new chemical products.

“The prevailing assumption is that these metal atoms are strongly bonded to each other and simply provide ‘landing spots’ for reactants. What everybody has assumed is that metal-metal bonds remain intact during the reactions they catalyze,” says Mavrikakis. “So here, for the first time, we asked the question, ‘Could the energy to break bonds in reactants be of similar amounts to the energy needed to disrupt bonds within the catalyst?'”

The answer, according to Mavrikakis’ modeling, is yes. The energy required for many catalytic processes to occur is sufficient to break bonds, allowing single metal atoms (known as adatoms) to break free and begin traveling on the surface of the catalyst. These adatoms combine to form clusters, which serve as sites on the catalyst where chemical reactions can occur much more easily than the catalyst’s original rigid surface.

The team examined the industrially important interactions of eight transition metal catalysts and 18 reactants using a set of special calculations, identifying energy levels and temperatures likely to form such small metal clusters, as well as the number of atoms in each cluster, which can also dramatically affect reaction rates.

Their experimental collaborators at the University of California, Berkeley, examined carbon monoxide adsorption on nickel (111), a stable, crystalline form of nickel useful in catalysis, using atomically-resolved scanning tunneling microscopy. Their experiments confirmed models that showed that various defects in the catalyst’s structure can also influence how single metal atoms pop loose and how reaction sites form.

According to Mavrikakis, the new framework is challenging the foundation of how researchers understand catalysis and how it occurs. It may also apply to other non-metal catalysts, which he will investigate further in future work. It is also important for understanding other important phenomena, such as corrosion and tribology, or the interaction of moving surfaces.