Atomically ordered intermetallic nanoparticles are promising for catalytic applications, but they are difficult to produce because the high-temperature annealing required for atom ordering inevitably accelerates metal sintering, resulting in larger crystallites.

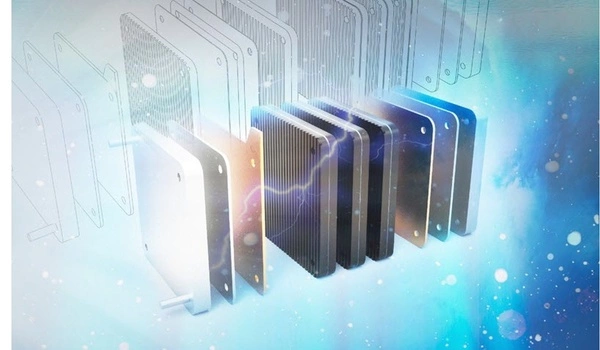

Platinum plays an important role in fuel cell catalysts, but its high cost limits the commercialization of fuel cells. Given this constraint, scientists created intermetallic compounds (IMCs) as promising low-Pt electrocatalysts. However, the synthesis of IMCs remains difficult because direct high-temperature annealing easily leads to alloy sintering, enlarging the nanoparticle and decreasing Pt availability.

A research group led by Prof. Liang Haiwei of the Chinese Academy of Sciences recently developed a small molecule-assisted impregnation approach to realize the general synthesis of carbon-supported platinum intermetallic fuel cell catalysts. The findings were published in the journal Nature Communications.

According to the research, STG coordinates with Pt and Co via a sulfhydryl group and a carboxylate group to form the precursors, which gradually decompose during annealing to form PtCo bimetallic clusters and release STG.

Liang’s team and collaborators previously achieved sulfur-anchoring synthesis. The use of commercialized carbon black, on the other hand, brought the discovery one step closer to widespread application.

The scientists first screened some small molecules containing heteroatoms as additives in the impregnation and suppressed PtCo sintering, with the additive-free group serving as a control.

“Notably, sulfhydryl group-containing molecules…exhibited outstanding capacity for suppressing PtCo sintering,” the researchers wrote in their paper, with water-soluble sodium thioglycolate (STG) emerging as the best additive.

Following that, the annealing conditions were optimized to produce 18 binary Pt-IMCs catalysts with relatively small particle sizes, and the resulting structure met expectations, with a uniform distribution of nanoparticles, base metal elements, and atoms. Six synthesized catalysts were evaluated and found to have high activity, capacity, and durability.

Why does STG function? According to the research, STG coordinates with Pt and Co via a sulfhydryl group and a carboxylate group to form the precursors, which gradually decompose during annealing to form PtCo bimetallic clusters and release STG. To suppress PtCo sintering, the STG eventually converts into a physical protective carbon coating and provides chemical Pt-S interaction with doped S.

The study also shed some light on the use of Pt intermetallic catalysts in other types of energy-conversion electrocatalysis and heterogeneous catalysis.