A solid copper-based covering created by Dartmouth School scientists can be unequivocally coordinated into texture to make responsive and reusable materials like defensive hardware, ecological sensors, and smart channels, as indicated by a new report.

The covering answers the presence of harmful gases in the air by changing them into less poisonous substances that become caught in the texture, the group reports in the Journal of American Synthetic Culture (JACS).

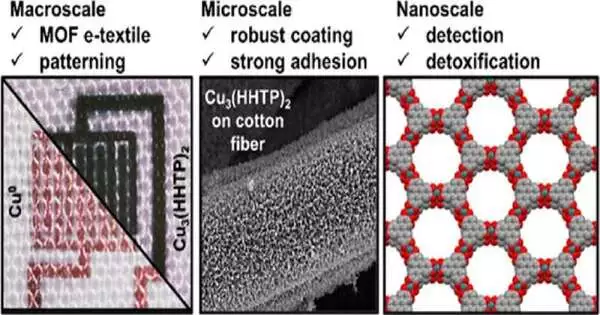

The discoveries depend on a conductive metal-natural innovation, or structure, created in the lab of their creator, Katherine Mirica, an academic administrator of science at Dartmouth. First detailed in JACS in 2017, the structure was a straightforward covering that could be layered onto cotton and polyester to make shrewd textures the scientists named Delicate—Self-Coordinated System on Materials. Their paper showed the way that delicate, shrewd textures could recognize and catch poisonous substances in the general climate.

For the freshest review, the specialists viewed that as meaning that, rather than the basic covering revealed in 2017, they can definitively implant the system into textures utilizing a copper precursor that permits them to make explicit examples and all the more successfully fill in the small holes and openings between strings.

“This technological breakthrough paves the path for other uses of the framework’s combined filtration and sensing capabilities, which could be useful in biomedical settings and environmental cleanup.”

Katherine Mirica, an associate professor of chemistry at Dartmouth.

The specialists found that the structure innovation really changed the poison nitric oxide into nitrite and nitrate and changed the toxic, combustible gas hydrogen sulfide into copper sulfide. They also claim that the structure’s ability to catch and convert poisonous materials has been tested through mileage and standard washing.

The flexibility and strength the new technique gives would permit the structure to be applied for explicit purposes and in additional exact areas, like a sensor on defensive clothing or as a channel in a specific climate, Mirica said.

“This new strategy for the statement implies that the electronic materials might actually interact with a more extensive scope of frameworks since they’re so robust,” she said. “This mechanical development prepares for various applications of the system’s combined filtration and detection abilities, which could be significant in biomedical settings and ecological remediation.”

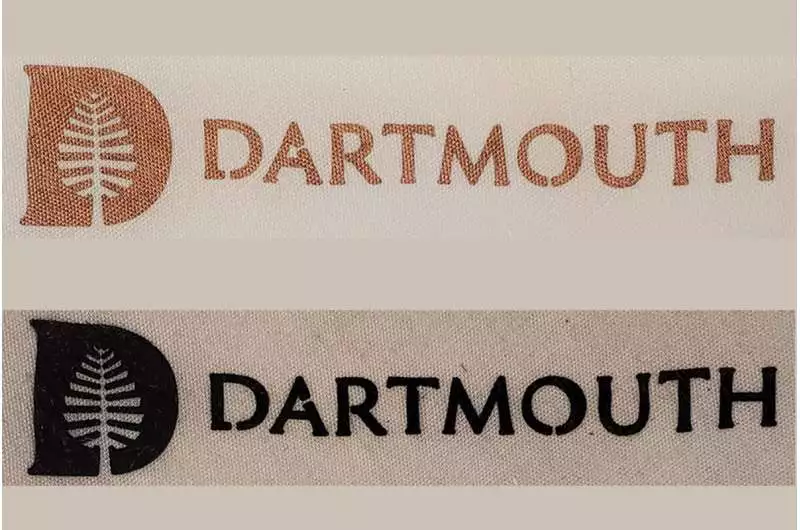

The copper engraved on the texture (top) is supplanted with a metal-natural system (base) fit for recognizing and catching harmful gases.

According to Mirica, the procedure could eventually be a low-cost alternative to innovations that are costly and limited in where they can be conveyed by requiring an energy source or, like exhaust systems in vehicles, uncommon metals.

“Here, we’re depending on an earthly abundance to detoxify poisonous synthetics, and we’re doing it with practically no contribution of outside energy, so we don’t require high temperatures or electric flow to accomplish that capability,” Mirica said.

Co-first creator Michael Ko, who accepted his Ph.D. in science from Dartmouth in 2020, first noticed the new cycle in 2018 as he endeavored to store the metal-natural system onto dainty film copper-based terminals, Mirica said. However, the copper cathodes would be supplanted by the structure.

“He needed it on top of the anodes, not to supplant them,” Mirica said. “It took us four years to sort out what was occurring and how it was valuable.” “It’s a very clear cycle, but the science behind it isn’t, and it took us a few investments and extra inclusion of understudies and colleagues to understand that.”

The group found that the metal-natural system “develops” over copper, supplanting it with a material with the capacity to channel and change over harmful gases, Mirica said. Ko and co-creator Lukasz Mendecki, a postdoctoral researcher in the Mirica Gathering from 2017–18, examined techniques for applying the structure material to texture in unambiguous plans and examples.

Co-first creator Aileen Eagleton, an alumni understudy in the Mirica Gathering, finished the procedure by enhancing the cycle for engraving the metal-natural system onto texture as well as recognizing what its design and properties are meant for by substance openness and response conditions.

Future work will zero in on growing new multifunctional system materials and increasing the most common way of implanting metal-natural coatings into texture, Mirica said.

More information: Aileen M. Eagleton et al, Fabrication of Multifunctional Electronic Textiles Using Oxidative Restructuring of Copper into a Cu-Based Metal–Organic Framework, Journal of the American Chemical Society (2022). DOI: 10.1021/jacs.2c05510