Material scientists have recently developed novel materials with a variety of advantageous properties that have the potential to improve the performance of various devices and technologies. Hydrogel-based fibers and synthetic skins, which could be used to make soft humanoid robots, prosthetics, and even comfortable smart clothes or wearable devices, are included in this category.

New robust, self-healing, and crack-resistant hydrogel-based microfibers were recently developed by researchers at Donghua University in China. A method that was influenced by the way spiders spin their webs was used to create these microfibers, which were first published in Nature Communications.

Shengtong Sun, one of the study’s authors, told Tech Xplore, “We noticed that although many synthetic hydrogel fibers have been synthesized to mimic the basic functions of biological fibers like silk, muscle, and nerve fibers, most of them have very poor damage resistance, which greatly limits their durability.” The structure of spider silk, which represents nearly the limit of the toughness of known natural biological materials, may provide a solution to this problem.

“We discovered that, despite the fact that many synthetic hydrogel fibers have been synthesized to mimic the basic functions of biological fibers such as silk, muscle, and nerve fibers, the majority of them have very poor damage resistance, which severely limits their durability,”

Shengtong Sun, one of the researchers who carried out the study,

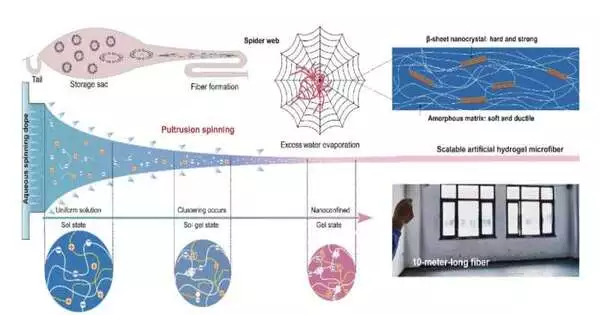

Bugs turn serious areas of strength for exceptionally strong networks into a watery dope, a fluid, translucent arrangement in which protein particles can move unreservedly while holding some level of request. They produce webs that adhere to a nanoconfined structure that is hierarchical and has advantageous mechanical properties.

“We imagined that the ionic complex of a hygroscopic, decidedly charged polyelectrolyte (PDMAEA-Q) and polymethacrylic corrosive (PMAA) could be an optimal framework to create harm-lenient hydrogel strands.” Sun elaborated. Strong hydrogen-bonded clusters of PMAA would be embedded in the ionic complex-filled soft matrix of the fiber. This could hypothetically emulate the nanoconfined construction of arachnid silk for a superior mechanical presentation.”

The researchers’ hydrogel microfibers were made in the same environment that spiders use to make their webs. “The spontaneous nanoconfinement of PMAA chains (H-bonded clusters) naturally occurs during water evaporation as separated nanophases embedded in the soft PDMAEA-Q/PMAA matrix,” Sun stated. “The fibers were formed using a technique known as pultrusion spinning.” Hydrogel microfibers with extremely high mechanical properties are produced through this hierarchical nanoconfinement. For instance, the hydrogel fiber has an elongation of 219 percent and a Young’s modulus of 428 MPa, making it quite durable.

In the beginning assessments, the microfibers made by the specialists showed exceptionally encouraging properties. For example, they were found to have a high damping limit and break opposition, as well as a high aversion to dampness that permitted them to contract, hold explicit shapes, and quickly “self-recuperate” when harmed.

“As a general rule, the high mechanical properties require solid covalent holding, while the quick fixing capacity requires exceptionally powerful organizations, which are innately incongruous,” Sun said. “Using a nanoconfined structure resembling spider silk, we address this issue. Importantly, this hierarchical structure emerges on its own during the evaporation of water, avoiding the time-consuming and energy-intensive steps required for additional treatment.”

The new work by this group of analysts could before long motivate the creation of other profoundly performing stringy materials in light of nanoconfined structures and comparable turning processes. Moreover, the bug silk-enlivened hydrogel microfibers they made could soon be applied and assessed in certifiable settings, for example as the activating strands of prosthetic appendages or wearable gadgets.

Sun continued, “We have demonstrated that hydrogel fibers with a nanoconfined structure can display very good properties, but the fibers’ toughness is not yet comparable to that of real spider silk.” Later on, we will attempt to present significantly more grounded nanocrystals as nanoconfinement for additional work on the mechanical properties of hydrogel filaments.”

More information: Yingkun Shi et al, Aqueous spinning of robust, self-healable, and crack-resistant hydrogel microfibers enabled by hydrogen bond nanoconfinement, Nature Communications (2023). DOI: 10.1038/s41467-023-37036-4