Without the power of contact, vehicles would slip off the street, people couldn’t walk down the walkway, and items would tumble off your kitchen counter and onto the floor. All things being equal, how rubbing works at a sub-atomic scale remains inadequately comprehended.

A team led by a postdoctoral scientist at Johns Hopkins Whiting School of Design and Krieger Institute of Expressions and Sciences used complex displaying and virtual experiences to focus on contact at both the subatomic and plainly visible scales.The group’s review findings, which appear in ACS Nano, shed light on rubbing in general, but could also illuminate the strategy for worked-on prosthetic gadgets and counterfeit joints.

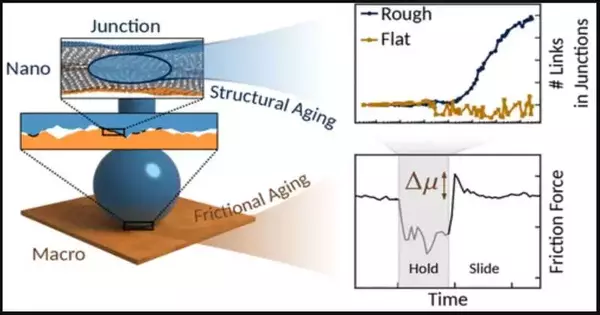

“Rubbing is perplexing in light of the fact that it isn’t represented by a solitary communication, similar to fascination between charges; it arises out of a mix of cycles that can happen at various scales.” In our work, we attempted to connect the nano- and full-scale universes for a specific type of rubbing known as maturing, which is the point at which one strong lays on another for an extended period of time without sliding, with the power expected to slide them apart in small increments.”We needed to figure out why,” said Lucas Frérot, presently a postdoc at Albert-Ludwigs-Universität’s Institut für Mikrosystemtechnik.

“Our simulation allowed us to test things that were not possible in experiments, such as what would happen if the surfaces came into touch with one other in a mathematically flat manner,”

Jaafar El-Awady, professor of mechanical engineering at the Whiting School.

Research colleagues at the Laboratoire de Tribologie et Dynamique des Systèmes at the École Centrale de Lyon in France recently directed tests that gave an extremely nitty-gritty image of the erosion reaction of surfaces covered with unsaturated fats, a harmless group of oils to the ecosystem, but those by themselves couldn’t make sense of the peculiarity behind maturing.

Using surface roughness estimations and the properties of the single-particle thick layer of unsaturated fat particles, the Johns Hopkins group was able to replicate the maturing system in a sub-atomic reproduction.

“Our reenactment permitted us to attempt things unthinkable in tests, for example, what might occur in the event that the surfaces in contact were numerically level,” said colleague Jaafar El-Awady, teacher of mechanical design at the Whiting School.

They observed that the primary driver of maturing was surface unpleasantness. As a matter of fact, the models without harshness didn’t progress in years by any stretch of the imagination, as per Frérot.

“This was remarkable because the surface roughness estimated by the group in Lyon was minuscule; the most noteworthy mountain and the most profound valley of the surface would be separated by about the length of one unsaturated fat particle,” he said.

The group presumed that even such a modest quantity of unpleasantness is sufficient to keep the particles from connecting over the entire surface, leaving the particles on the edges of contact spots free to move. Over the long haul, more particles come in contact, bringing about maturing.

Although the discovered instrument does not explain why frictional frameworks age, the group believes it could be applied to a wide range of frameworks where chain-like particles, such as the unsaturated fats they focused on, structure a defensive layer on a surface.

“This is the situation in natural frameworks like joints, and assuming that we comprehend those frameworks better, we can configure better and more sturdy prostheses.” In a more broad sense, understanding the physical science behind grating is significant in the design of manageable frameworks. “A few examinations gauge that around 23% of the world’s energy utilization is lost to grinding,” Frérot said.

Research colleagues note that the plan of the recreations utilized in this study was initially imagined by Imprint O. Robbins, a previous partner at Johns Hopkins’ Division of Material Science and Stargazing, who passed away in 2020.

“Lucas and I then, at that point, kept on pushing on the reproductions with our partners to accomplish their objectives effectively and to commit them to Stamp’s memory,” El-Awady said.

More information: Lucas Frérot et al, From Molecular to Multiasperity Contacts: How Roughness Bridges the Friction Scale Gap, ACS Nano (2023). DOI: 10.1021/acsnano.2c08435

Journal information: ACS Nano