Great data transmission, high-accuracy data detection, and high-awareness signal location are important ways to achieve precise insight and viable ID.Elite execution chips, terahertz transmission T/R parts, and outrageous climate sensor producing advances have become key boondocks research areas of interest. Its viability is based on the ultra-accuracy miniature nanoproducing level of the complex microstructure of its core useful gadgets.As a great transporter for data-enabled center useful gadgets, unadulterated copper metal has super high electrical conductivity, warm conductivity, and high pliability, as well as low-misfortune signal transmission abilities. Hence, it has gotten broad consideration in the field of miniature nanoproduction.

As of late, Prof. Huadong Yu, researcher Jinkai Xu, Wanfei Ren, Zhongxu Lian, Xiaoqing Sun, and Zhenming Xu from Changchun University of Science and Technology have composed an article titled “Limited Electrodeposition Micro Additive Manufacturing of Pure Copper Microstructures” in the International Journal of Extreme Manufacturing. In this article, the writers efficiently presented the limited advancement of the miniature added substance material assembling strategy for the miniature unadulterated copper structure and worked on the made microstructure for execution testing.

Teacher Huadong Yu (a teacher of Jilin University and the main innovation official of the Key Laboratory of Cross-scale Micro-Nano Manufacturing of the Ministry of Education), Jinkai Xu ( a teacher of CUST and the head of the National and Local Joint Engineering Laboratory of Precision Manufacturing and Detecting Technology/Key Laboratory of Cross-scale Micro-Nano Manufacturing of the Ministry of Education and the head of the miniature nano producing discipline of CUST), and Wanfei Ren (a speaker of CUST) have fostered a couple of techniques for assembling microstructures The subtleties are as per the following:

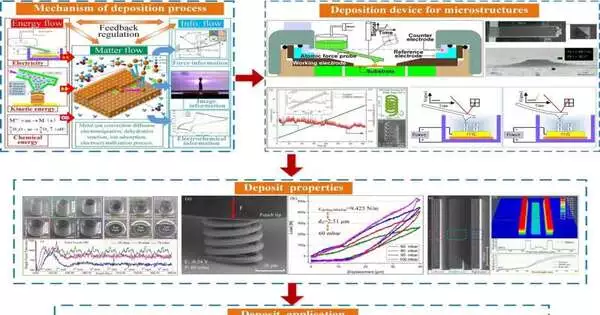

“A mathematical model of the interaction between the atomic force servo, focusing electric induction, and pulsed micro-jet was proposed by the authors of this paper. This initial model of electrochemical deposition, material transport, and force information feedback is established by this model, despite it being preliminary.”

Professor Huadong Yu

“While the method shows the creation of unadulterated copper microstructures, the innovation has applications as soon as 2018. What are the primary commitments of this paper? “

“The creators in this paper proposed a numerical model of the collaboration of beat miniature flies, centering on electric enlistment and nuclear power servo. This model lays out the underlying model of electrochemical testimony, material vehicle, and power data input.

“The article mostly presents the different qualities of the unadulterated copper microstructure. Could you at any point momentarily present it? “

The production of unadulterated copper microstructure was understood, and the affidavit rate was 0.887 m/s. The shear modulus of an unadulterated copper microspring was tried and reached 60.8GPa. “

“What is the job of the gadget during the trial?”

“The gadgets utilized in the trial are from Exaddon AG, Switzerland. The capability of the gadget is to screen the condition of the statement cycle during the trial. On account of the gadget, the Z-course position of the nuclear power test and the bowing condition of the cantilever can be identified online simultaneously.

More information: Wanfei Ren et al, Localized electrodeposition micro additive manufacturing of pure copper microstructures, International Journal of Extreme Manufacturing (2021). DOI: 10.1088/2631-7990/ac3963