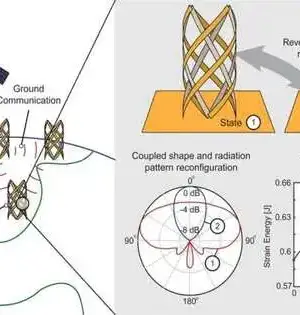

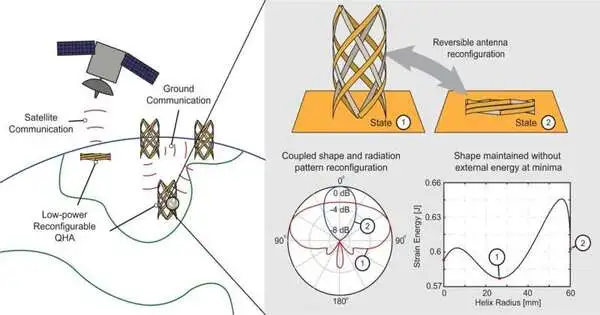

Scientists from Stanford and the American College of Beirut have developed a lightweight, compact receiving wire that can speak with satellites and gadgets on the ground, making it simpler to organize salvage and aid projects in calamity-prone regions. At the point when a seismic tremor, flood, or other event goes horribly wrong for a locale, existing correspondence foundations, for example, cell and radio pinnacles, are frequently harmed or obliterated. Reestablishing crisis interchanges as fast as possible is indispensable for planning salvage and aid projects. Scientists at Stanford College and the American College of Beirut (AUB) have fostered a versatile receiving

Engineering

A threesome of delicate mechanical technology specialists at Fondazione Istituto Italiano di Tecnologia, in Italy, working with a partner from the College of Montpellier, in France, has fostered a remarkable sort of robot that 3D prints its own body as a way to develop longer. In their paper distributed in the journal Science Advanced Mechanics, the gathering depicts how they made their robot and the potential purposes for it. As science and innovation keep on developing, researchers track down clever ways of joining advancements into new sorts of innovation. In this new endeavor, the exploration group joined mechanical technology with

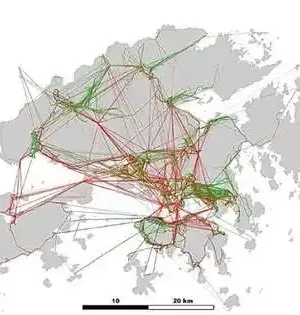

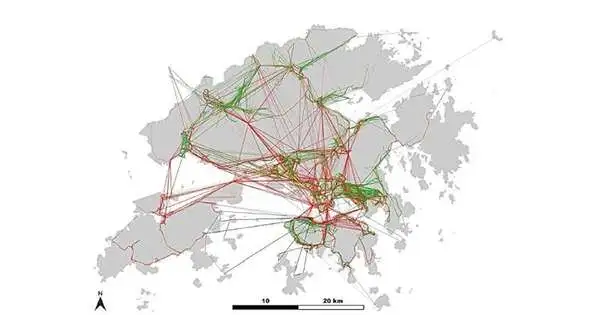

Urban areas are sustaining the versatility of their metropolitan framework organizations to handle expected unanticipated interruptions, especially because of outrageous weather conditions coming about because of environmental change. As of late, scientists from City College of Hong Kong (CityU) have involved the Hong Kong public vehicle framework in a contextual analysis to uncover the essential role of interconnections between various transportation modes in reinforcing framework strength against unfriendly disturbances. The review gives important insights into how interconnectedness fundamentally further develops network power, introducing another methodology for planning metropolitan organizations like foundations around the world. Named "Interconnectedness improves network strength of

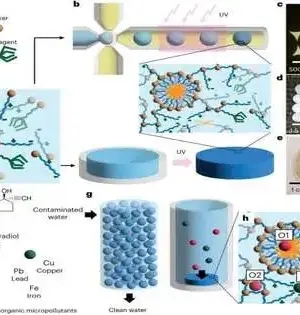

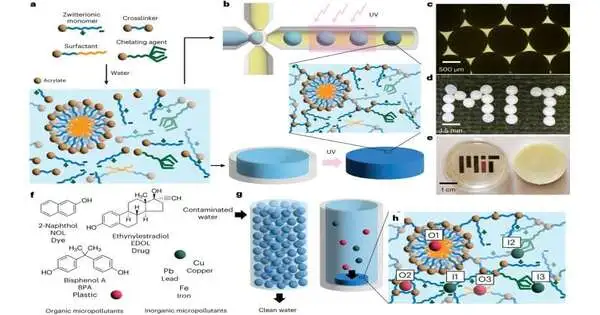

"Zwitterionic" probably won't be a word you go over each day; however, for Teacher Patrick Doyle of the MIT Division of Compound Designing, it's a word that is key to the innovation his gathering is creating to eliminate micropollutants from water. Gotten from the German word "zwitter," signifying "mixture," "zwitterionic" atoms are those with an equivalent number of positive and negative charges. Devashish Gokhale, a Ph.D. understudy in Doyle's lab, utilizes the case of a magnet to portray zwitterionic materials: "On a magnet, you have a north pole and a south pole that adhere to one another, and on a

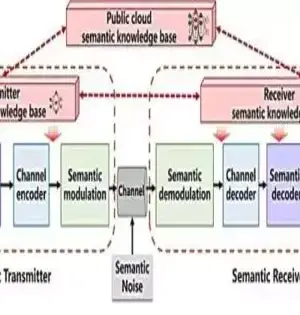

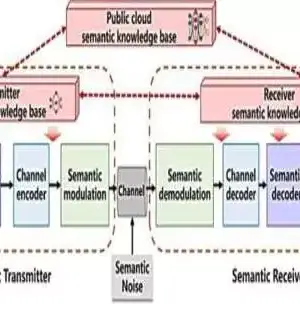

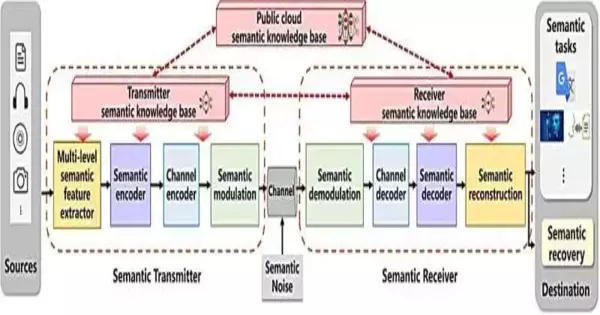

This study was driven by Prof. Ping Zhang, Dr. Yiming Liu, Yile Melody, and Jiaxiang Zhang (State Key Research Center of Systems Administration and Exchanging Innovation, Beijing College of Posts and Broadcast Communications). Their article sums up the advances made in semantic data and semantic correspondences. It additionally talks about the primary difficulties, central points of contention, and potential examination headings in creating present-day semantic correspondence, expecting to provoke further logical and modern advances in semantic interchanges. The improvement of data and correspondence innovation (ICT) fundamentally affects current culture. The development of portable correspondence frameworks from the original (1G) to

This study was driven by Prof. Ping Zhang, Dr. Yiming Liu, Yile Tune, and Jiaxiang Zhang (State Key Research Facility of Systems Administration and Exchanging Innovation, Beijing College of Posts and Media Communications). Their article sums up the advances made in semantic data and semantic correspondences. It likewise talks about the primary difficulties, central questions, and potential exploration bearings in creating present-day semantic correspondence, meaning to provoke further logical and modern advances in semantic correspondence. The improvement of data and correspondence innovation (ICT) essentially affects current culture. The development of versatile correspondence frameworks from the original (1G) to the fifth

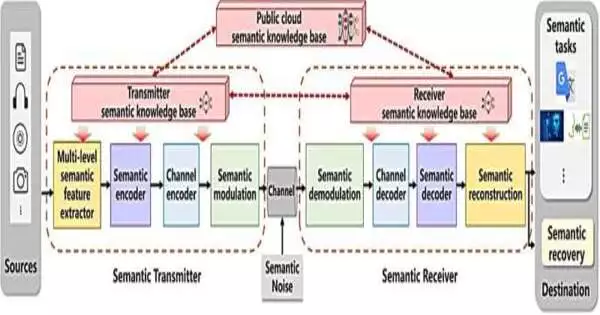

A meta-fabric made of microfibers has been created by engineers, materials scientists, and chemists at Nankai University in China. It allows the wearer to regulate their body temperature throughout the day, even when the outside temperature fluctuates. In their paper distributed in the journal Science, the gathering depicts how they fostered their textures, how they work, and how well they performed when tried. In the same issue of the journal, Xingyi Huang and Pengli, both from Shanghai Jiao Tong University in China, have written a Perspective article about the team's work. As the specialists note, clothing keeps individuals warm when

A new study provides compelling evidence that music preferences can provide insight into a person's moral values. It has discovered a significant link between music and morality, paving the way for a more in-depth understanding of the psychological dimensions of our musical experiences. A new study published in the journal PLOS ONE has discovered a remarkable link between people's musical preferences and their moral values, shedding new light on the profound influence music can have on our moral compass. A team of scientists from Queen Mary University of London and the ISI Foundation in Turin, Italy, conducted the study, which

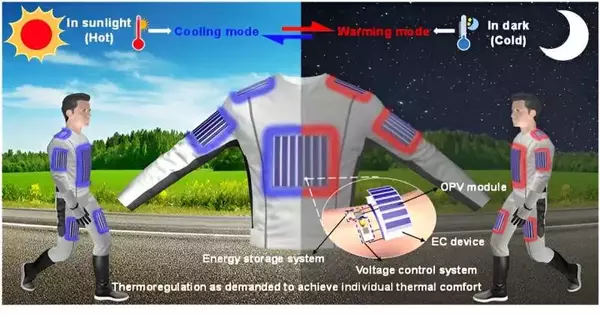

An exploration group led by Prof. Tian Xingyou and Prof. Zhang Xian from the Hefei Establishments of Actual Science (HFIPS) of the Chinese Institute of Science (CAS) has used fluid metal to build fluid metal/polyimide/polytetrafluoroethylene (LM/PI/PTFE) programmable photothermal actuators in light of awry warm extension. The review was distributed in Cutting Edge Utilitarian Materials as a title page. Dr. Li Xiaofei, the paper's first author, said, "We were inspired by the way a plant's tip-sensitive region contracts on one side to form tendrils." "The tendril-like actuator has customizable initial morphology." Traditional photothermal materials are being replaced in the process of

Scientists from Cornell Tech have fostered a strategy to recognize defers in the revealing of episodes, for example, brought down trees and electrical cables, which could prompt reasonable bits of knowledge and mediations for more fair, effective taxpayer-supported organizations. Their technique, which works without knowing precisely when an episode happened, utilizes the recurrence of reports of similar occurrences by independent people to assess the amount of time required for the occurrence to be first detailed. The primary report lays out that the episode happened, and ensuing reports are utilized to lay out the detailing rate. Applying their strategy to more