Knowing the areas of strength for how a piece of steel is, especially the treated steel used in everything from vehicles to structures, is critical for those who make and use it.This data assists with guarding individuals during crashes and keeping structures from falling.

Precisely foreseeing the strength of a steel model in view of its microstructure and piece would be key while planning new kinds of steel, yet it has been almost difficult to accomplish—as of recently.

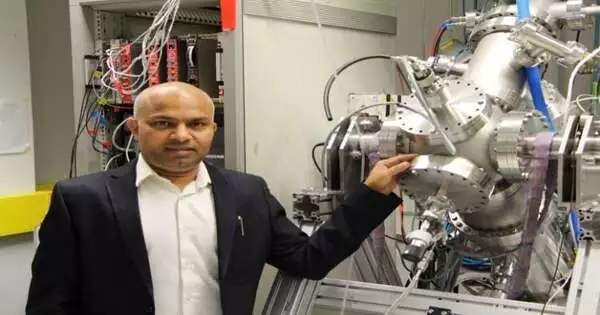

“Planning/making the best-strength steel is the hardest errand,” said Dr. Harishchandra Singh, an assistant lecturer at NANOMO and the Center for Advanced Steels Research at the University of Oulu in Finland.

Assessing the commitment of different elements towards planning high-strength novel steel has generally required various tests that can take months, as per Singh. Each test, likewise, requires another example of the model.

“Rather than spending several months on various lab-based testing, we can acquire entire knowledge about the crystalline microstructures from the synchrotron in one hour.”

Dr. Harishchandra Singh, an adjunct professor at NANOMO

Overall, Singh and his colleagues used the Canadian Light Source (CLS) at the University of Saskatchewan to predict the strength of a clever steel.

They focused the office’s synchrotron light on a little shape of steel and examined the diffraction design it created as the strong X-beams went through it. This gave information on the gem design of the steel that the scientists used to foresee its material properties, including strength, through a logical model.

The group found that these forecasts coordinated precisely with the information from serious, customary lab-based tests.

The group’s strategy offers a better approach to foreseeing the yield strength for profoundly alloyed complex steel. The cycle could likewise assist with designing novel materials through a superior understanding of the connection between a steel’s microstructure and its mechanical properties.

Notably, the synchrotron-based strategy for examining steel was similarly as solid as customary testing, yet it was a lot quicker and expected undeniably less material.

“We can get total data about the glasslike microstructures from the synchrotron in 60 minutes, as opposed to putting in several months of different lab-based testing,” he said. Their discoveries were published recently in the Journal of Materials Research and Technology.

This fast and exact synchrotron-based strategy for testing could be very useful to the steel business to gauge the strength of the created products and could save months compared with standard courses, said Singh.

“Steel organizations make many clumps of steel. “With synchrotron testing, they could have exact outcomes from each group that very day,” he said.

Steel engineers can utilize synchrotron examinations to rapidly and precisely foresee the strength of novel steel models and utilize the information to assist in recognizing what components of a model are useful or not. This quicker strategy for surveying and creating steel could prompt better structural materials to become available.

More information: Sumit Ghosh et al, Quantitative prediction of yield strength of highly alloyed complex steel using high energy synchrotron X-ray diffractometry, Journal of Materials Research and Technology (2022). DOI: 10.1016/j.jmrt.2022.07.066