A group of A*STAR researchers has effectively upcycled squandered polyethylene terephthalate (PET) plastic into polymer electrolytes, which are key parts for more secure lithium-particle batteries (LiBs). The review is the main known report of a functioning lithium-particle battery gathered using polymers upcycled from PET plastics, which are utilized to make plastic jugs.

The review was distributed in the November 2022 issue of the Diary of Materials Science.

Plastic waste is a mounting issue in this present reality, and it is set to become greater with the rising interest in plastics. 460 million tons of plastic were created worldwide in 2019, yet just 9% were reused, with the rest being burned or arranged in landfills and the climate.

Plastic waste is routinely reused through mechanical and compound cycles, which have their downsides. For mechanical reusing, only a small amount of reused PET can ultimately be utilized, as its actual properties degrade with each round of reusing because of polymer chain cleavage. Compound reusing involves high energy use, requires purged monomers, and can be more expensive compared with utilizing virgin polymers.

“Because of increased electrification, there is a rise in demand for ethically sourced materials for lithium-ion batteries. However, until recently, no one has used waste PET plastics as a feedstock for polymer electrolytes. This is our first attempt to repurpose leftover PET plastics for this purpose.”

Dr. Jason Lim, Deputy Head of the Soft Materials department at IMRE.

“Upcycling waste plastics is another system to give these universal yet usually discarded materials another lease of life by changing them into value-added new items for novel applications.” PET plastics offer incredible potential for upcycling because of their deeply rooted existing waste assortment framework and somewhat simple waste streams,” said Dr. Derrick Fam, Agent Top of the Polymer Composites division at A*STAR’s Foundation of Materials Exploration and Designing (IMRE), who drove this concentrate along with Dr. Jason Lim, Agent Top of the Delicate Materials division at IMRE.

“There is an ascent in popularity for reasonably obtained materials for lithium-particle batteries because of the more prominent zap.” Nonetheless, the utilization of waste PET plastics as an asset for polymer electrolytes has never been accomplished till now. “This addresses our most memorable endeavor to upcycle squandered PET plastics for this application,” said Dr. Lim.

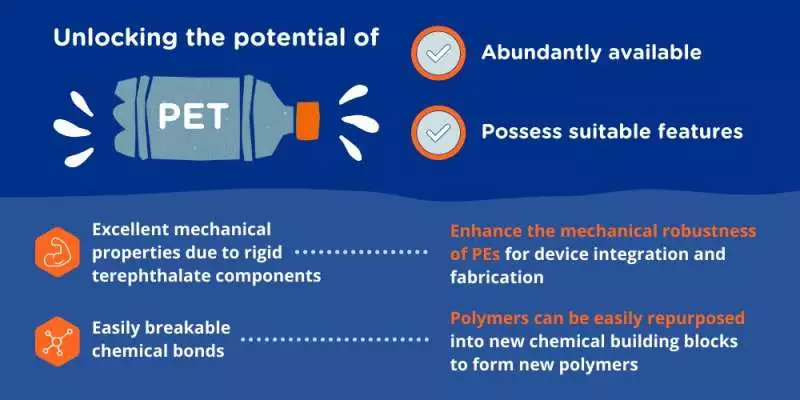

PET plastics contain a variety of recyclable elements.

Increasing the capability of pets: Taking advantage of existing properties

Among the various sorts of plastic, polyethylene terephthalate (PET) is perhaps the most abundant plastic created today, adding up to 31 million tons in 2019.

PET plastics have existing characteristics that make them reasonable candidates to be upcycled into polymer electrolytes (PEs). They are comprised of unbending terephthalate parts, which add to their great mechanical properties and can be tapped on to improve PEs’ mechanical power, which thus works with gadget mix and creation.

They also have relatively weak compound bonds, allowing these polymers to be easily recycled into new synthetic building blocks. These can then be reconstituted into new polymers for new applications.

From jugs to batteries: changing battery plans

Squandered PET jugs were utilized by the group to plan polyurethane-based PEs. Contrasted with regular fluid electrolytes right now utilized in LiBs, PEs are promising elective parts in batteries that can possibly kill security perils, for example, the dangers of electrolyte spillage, uncontrolled warming, volume extension, dendrite development, and fire risks.

Following a survey of the PET-derived polymers’ feasibility as strong polymer electrolytes, the group examined their ionic conductivity and cycling performance when used as gel polymer electrolytes for LiBs.

Discoveries from the review showed the capability of the polyurethanes made from squandered PET as polymer electrolytes for LiBs. As a gel-polymer electrolyte (GPE), they achieved a room temperature conductivity of OK S/cm, which is equivalent to existing business frameworks containing fluid electrolytes.The group also successfully assembled a working LiB using these polymers and demonstrated how cells can be repeatedly energized and released to 150 cycles.

Their promising exhibition prepares for a future fueled by more feasible energy, where PET plastic waste can be changed into PE materials for batteries, making a round economy while battling the mounting plastic waste issue. The group will also work to advance the technology for upcycling waste plastics for a broader range of applications, such as making parts for environmentally friendly batteries. This drive is in accordance with A*STAR’s endeavors to foster feasible answers for energy proficiency and waste administration.

More information: Ming Yan Tan et al, Upcycling waste poly(ethylene terephthalate) into polymer electrolytes, Journal of Materials Chemistry A (2022). DOI: 10.1039/D2TA06692K