One of the most dreary, overwhelming undertakings for undergrad partners in college research labs includes looking through a magnifying lens at tests of material, attempting to track down monolayers.

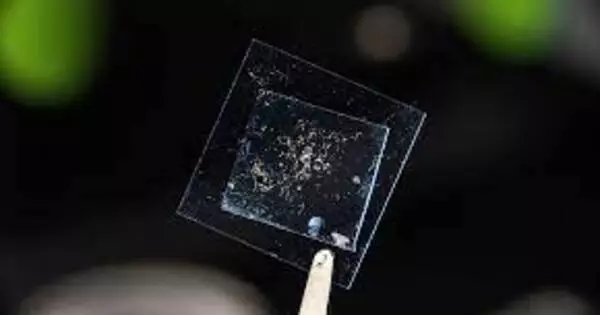

These two-layered materials—under 1/100,000th the width of a human hair—are exceptionally well suited for use in hardware, photonics, and optoelectronic gadgets due to their remarkable properties.

“Research labs recruit multitudes of students to just search for monolayers,” says Jaime Cardenas, an associate teacher of optics at the University of Rochester. “It’s extremely dreary, and assuming you get worn out, you could miss a portion of the monolayers or you could begin making misidentifications.”

Indeed, even after all that work, the labs should double-check the materials with costly Raman spectroscopy or nuclear power microscopy.

For those students, their examination labs, and organizations that experience comparable hardships in recognizing monolayers, Jess Sánchez Juárez has made life a ton more straightforward for them.

“Research labs pay armies of undergraduates to do nothing except look for monolayers. It’s boring, and if you become sleepy, you can miss some of the monolayers or start making mistakes.”

Jaime Cardenas, an assistant professor of optics at the University of Rochester,

The leading edge innovation, a computerized examining gadget depicted in Optical Materials Express, can distinguish monolayers with 99.9% precision, outperforming some other strategy to date.

for a portion of the expense. in significantly less time. promptly accessible materials.

“One of the fundamental targets was to foster a framework with a tiny spending plan so understudies and labs can repeat these techniques without spending a great many dollars just to purchase the essential hardware,” says Sánchez Juárez, the lead creator of the paper.

For instance, the gadget he made can be recreated with an economical magnifying instrument with a 5X objective focal point and a minimally expensive OEM (unique hardware producer) camera.

An imaginative variation of an AI brain organization

“We’re exceptionally energized,” Cardenas says. “Jess completed a few things here that are new and unique, applying man-made consciousness in an original method for tackling a significant issue in the utilization of 2D materials.”

Numerous labs have attempted to dispense with the requirement for expensive reinforcement portrayal tests by preparing a man-made brainpower (AI) brain organization to filter for the monolayers. Most labs that have attempted this approach endeavor to fabricate an organization without any preparation, which takes a lot of time, Cardenas says.

All things considered, Sánchez Juárez began with an openly accessible brain network called AlexNet that is now prepared to perceive objects.

He then fostered a clever cycle that reverses pictures of materials, so whatever was brilliant in the first picture rather seems dark, as well as the other way around. The transformed pictures go through extra handling steps. By then, the images “don’t look at all to the natural eye,” Cardenas says, “but for a PC, it makes it simpler to isolate the monolayers from the substrates they are kept on.”

Primary concern: Compared to those long, monotonous long stretches of checking by students, Sánchez Juárez’s framework can handle 100 pictures covering 1 centimeter x 1 centimeter-sized examples in a short time with close to 100 percent precision.

Sánchez Juárez writes in the paper that “our exhibit prepares for robotized creation of monolayer materials for use in research and modern settings by enormously lessening the handling time.” Applications incorporate 2D materials reasonable for photodetectors, excitonic light-radiating gadgets (LEDs), lasers, optical age of twist valley flows, single photon discharge, and modulators.