Nano-joints in the AgNWs Interconnect Network’s atomic flow behavior were discovered by researchers from Xi’an Jiaotong University. A combination of in-situ experiments and molecular dynamics simulations was used to investigate the thermal welding process and the atomic evolution behavior of Ag nanowires in order to further enhance the joint quality.

Throughout the process of creating various kinds of Ag nanowire joints, the team conducts a systematic analysis of the atomic flow behavior. The impact of handling time, temperature, and stress dispersion because of the spatial course of action on nanojoints was deliberately investigated. Likewise, the disappointment instruments and their nuclear connection points for the nanojoints were additionally explored. The industrial use of Ag nanowire interconnection networks in flexible electronics and transparent conductive films may benefit from these findings.

The study of the temperature dependence of joints and the thermal defect damage mechanisms during their welding process becomes increasingly important as the size of nanojoints decreases to the nanoscale. During welding, Ag nanowires exhibit a more pronounced capillary phenomenon in the nano-gaps, and their weld morphology is influenced not only by temperature but also by local stress.

“We directly witnessed the excitation and resorption of a large number of Ag nanoparticles on the surface of AgNWs during thermal excitation, and the mechanism of nanoparticle production may be related to capillary-induced surface diffusion and permeation,”

The author Xiaoying Ren

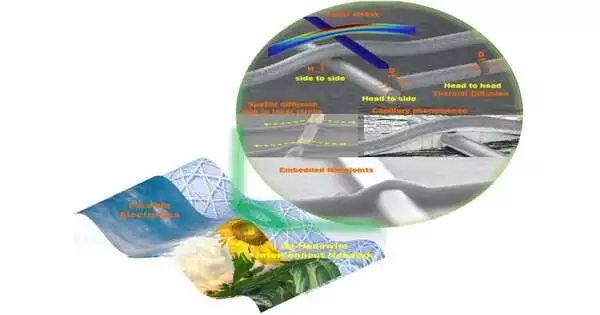

The initial spacing and alignment direction of the nanowires influence the final quality of the joint for thermally induced welding techniques. During the welding process, you can get three different kinds of nano-joints: joints from head to head, from side to side (T-shaped), and from side to side (X-shaped). In addition to temperature, the horizontal pitch has a major impact on the weld morphology for the first two joint forms. Due to the spatial structure of the top and bottom of X-shaped nano-joints, in addition to temperature, local stresses have a significant impact on the joint shape.

One of the lead specialists, Teacher Jianlei Cui, remarked, “The qualities of the joint in the interconnected organization of AgNWs are impacted by the temperature, yet in addition by the nearby pressure and its collaboration with the substrate, simultaneously narrow connections show a non-unimportant impact in the interfacial stream at the nanoscale. Additionally, as treatment time passes, the joint’s atomic flow improves within the appropriate temperature range, and the joint’s quality improves as well.”

The evolution of the atomic morphological features during the welding of Ag nanowires can be directly observed and analyzed thanks to the electron microscope’s in-situ heating system. “The mechanism of nanoparticle formation may be due to capillary-induced surface diffusion and permeation,” the author, Xiaoying Ren, stated. “In our work, we directly observed the excitation and resorption of a large number of Ag nanoparticles on the surface of AgNWs during thermal excitation.”

The excitation and reabsorption of these nanoparticles are joined by a steady filling of the nanogaps with Ag particles, forming completely welded nano-joints with expanding time.

The authors discovered that AgNWs generate certain stress concentrations in parts with curvature, which typically exhibit local damage or fracture under thermal excitation in the subsequent process. They further investigated the effect of local stress on X-shaped nano-junctions.

During the development of an X-joint, the upper nanowires will be fiercely affected by neighborhood stress and temperature, and their iotas will stream along the outer layer of the lower nanowires, in the end framing an exemplified nano-joint, which prompts the arrangement of an enormous number of deformities on the two sides of the upper nanowire joint, and these X-formed nano-intersections are quick to break on the two sides of the upper nanowires during the later warm excitation process.

“We have systematically analyzed the Rayleigh destabilization of Ag nanowires under thermal excitation using molecular dynamics simulations, and the results show that Ag nanowires form equally spaced nanoparticles due to Rayleigh destabilization at high temperatures,” the author Chenchen Huang stated. This was done in order to further investigate the evolution of the atomic behavior of Ag nanowires under thermal excitation as well as the mechanism of thermal damage.

“How to effectively improve the welding quality of AgNWs joints and ensure the application stability of the joints has always been the focus of research,” Professor Xuesong Mei stated. The thermal sensitivity and thermal damage mechanisms of nano-joints in the application process will also receive more and more attention in the future as devices become smaller and more integrated.

The study has been accepted for publication in the International Journal of Extreme Manufacturing.

More information: Jianlei Cui et al, Morphological characteristics and atomic evolution behavior of nanojoints in Ag nanowire interconnect network, International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/acc434