The energy density of lithium-ion batteries is increased by an ultrathin braided wire in the core of an electrode, according to a team of researchers in the journal Angewandte Chemie International Edition. This kind of battery could be used to power smartphones and other electronic devices while we wear them by being incorporated into functional textiles. The new twisted current gatherer structure replaces a solitary nonstop wire and further develops particle transport inside the cathode, expanding charge thickness.

Smartphones and electric automobiles all use lithium-ion batteries (LIBs). They are what we know to be made of a stack of electrodes with a big or cylinder shape. In a novel battery variant, the stack is reduced to the size of a thread made up of two long electrode fibers wound around each otherwith a big or cylinder shape. In a novel battery variant, the stack is reduced to the size of a thread made up of two long electrode fibers wound around each other. These very light fiber batteries (FLIBs) can power wearable electronics because they are woven into fabric. In 2022, fiber batteries were named one of IUPAC’s Top Ten Emerging Chemistry Technologies.

“The designed braiding structure leads to active material-filled channels, reducing obstruction to lithium ion transport and increasing active material loading capability.”

A team of researchers

However, before fiber batteries can be used to power functional clothing, tents, and other items, there is a problem that needs to be fixed: the energy density is far too low in long fibers to be useful. Now, Huisheng Peng and his colleagues at Fudan University in Shanghai (China) have discovered that this issue could be resolved by redesigning the electrode’s current collector.

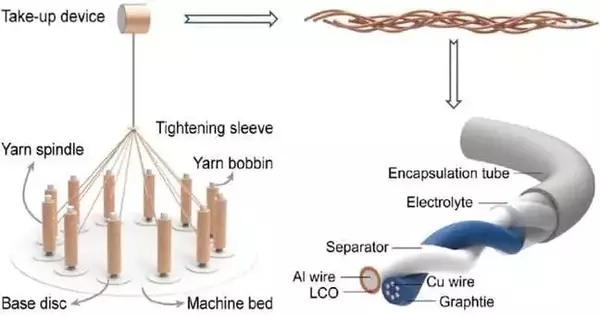

The group chose to supplant the ongoing gatherer, which is a consistent, dainty metal wire inside the graphite terminal, with a mesh made of a few much more slender metal strings. They braided several extremely thin metal threads from spindles into a central braided thread before coating the entire electrode in graphite to create the braid.

The new plaited current authority was similarly just about as steady as the constant wire, which made it conceivable to build the energy thickness by connecting with the graphite. “The designed braiding structure leads to channels filled with active materials, reducing obstruction to lithium ion transport and increasing the loading capability of active materials,” states the group’s explanation.

This expanded energy thickness was likewise shown in tests: 40 one-meter-long FLIBs with braided current collectors were woven into a textile. A smartphone could be charged using this FLIB-based textile from 30% to 57%, while the conventional FLIB design with a continuous current collector wire could only reach 52%.

Changing the current collector’s design was all it took to achieve this efficiency boost. This is especially crucial for long-fiber batteries, which must be lightweight while still being strong and stable.

More information: Xinlin Huang et al, Braided Fiber Current Collectors for High‐Energy‐Density Fiber Lithium‐Ion Batteries, Angewandte Chemie International Edition (2023). DOI: 10.1002/anie.202303616