According to Gartner, Inc.’s most recent projection, 5G+ (5G/Beyond 5G) is the fastest-growing segment and the only substantial opportunity for investment growth in the wireless network infrastructure industry. However, existing 5G+ technologies rely on massive antenna arrays, which are often heavy and available in only a few sizes, making them difficult to transport and costly to tailor.

To address the issue, researchers from Georgia Tech’s College of Engineering devised an innovative and adaptable solution. Their tile-based additively manufactured technique can build on-demand, massively scalable arrays of 5G+ (5G/Beyond 5G) enabled smart skins with the ability to allow intelligence on practically any surface or object. The study, which was just published in Scientific Reports, describes the approach, which is not only easier to scale and adapt than current practices, but also does not degrade performance when flexed or scaled to a very high number of tiles.

Typically, several smaller wireless network systems collaborate, but they are not scalable. You can’t increase, decrease, or direct bandwidth using current techniques, especially for very broad areas, “Tentzeris stated. “Being able to use and scale this unique tile-based technique enables this.”

Tentzeris claims that his team’s modular application with 5G+ capability has the potential for immediate, large-scale effect as the telecom industry swiftly transitions to standards for faster, larger capacity, and reduced latency communications.

Making the tiles

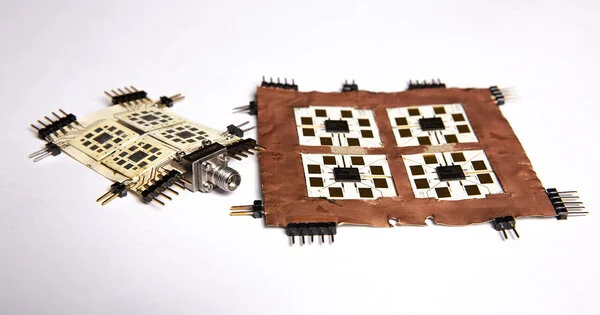

Flexible and additively made tiles are placed on a single flexible underlying layer in Georgia Tech’s novel technique. This enables tile arrays to be attached to a wide range of surfaces. The architecture also enables the installation of very large 5G+ phased/electronically steerable antenna array networks on the fly. According to Tentzeris, connecting a tile array to an unmanned aerial vehicle (UAV) is also a potential for increasing broadband capacity in places with limited coverage.

In the study, the researchers created a flexible 55-centimeter tile array and wrapped it around a 3.5-centimeter radius curvature as a proof-of-concept. Each tile contains an antenna subarray and an integrated, beamforming integrated circuit on an underlying tiling layer, resulting in a smart skin that can seamlessly interconnect the tiles to form very large antenna arrays and massive multiple-input multiple-output (MIMOs)—the practice of housing two or more antennas within a single wireless device. Tile-based array topologies on solid surfaces with single antenna elements have previously been investigated, but they lack the modularity, additive manufacturability, and flexible implementation of the Georgia Tech concept.

The proposed modular tile solution allows for the production of tiles of equal sizes in large quantities that are easily replaceable, lowering the cost of personalization and maintenance. This technique essentially combines replaceable pieces, modularity, vast scalability, low cost, and flexibility into a single system.

5G+ is just the beginning.

While the tiling architecture has shown the ability to significantly improve 5G+ technologies, the Georgia Tech team believes that its mix of flexible and conformal capabilities has the potential to be deployed in a wide range of environments.

“The design and features of each tile scale can be unique, accommodating different frequency bands and power levels,” Tentzeris explained. One may be a communications tile, another could be a sensor tile, and yet another could be an energy harvester tile for solar, thermal, or ambient RF energy. The tile framework’s application is not restricted to communications. “

The Internet of Things, virtual reality, and smart manufacturing/Industry 4.0—a technology-driven strategy that uses internet-connected “intelligent” machinery to monitor and fully automate the manufacturing process—are other areas of application the team is enthusiastic about investigating.

“Because of the tile architecture’s mass scalability, it has a wide range of applications and is practically ubiquitous. We’re headed in a path where everything will be covered in some type of wireless conformal smart skin encompassing a communication system or antenna that enables for effective monitoring, from dams and buildings to industrial or cars, down to individual health-monitoring gadgets.”

Tentzeris

Because of the tile-mass architecture’s scalability, its applications are exceptionally diverse and nearly ubiquitous. From dams and buildings to machinery and automobiles, to individual health-monitoring devices, “Tentzeris said. “We’re headed in the direction of covering everything in some kind of wireless conformal smart skin that includes a communication system or antenna that enables effective monitoring.”

The team is now looking forward to putting the approach to the test on huge, real-world structures outside of the lab. They are currently working on the fabrication of considerably bigger, fully inkjet-printed tile arrays (256+ elements), which will be presented at the next International Microwave Symposium (IEEE IMS 2022), the premier IEEE conference on RF and microwave engineering. The IMS presentation will feature a new tile-based large-area architecture version that will enable the rapid and low-cost assembly of configurable tile arrays for a variety of conformal platforms and 5G+ enabled applications.