As electric vehicles gain popularity, the spotlight shines brighter on some of their major issues.Analysts at The College of Texas at Austin are handling two of the greater difficulties confronting electric vehicles: restricted range and slow re-energizing.

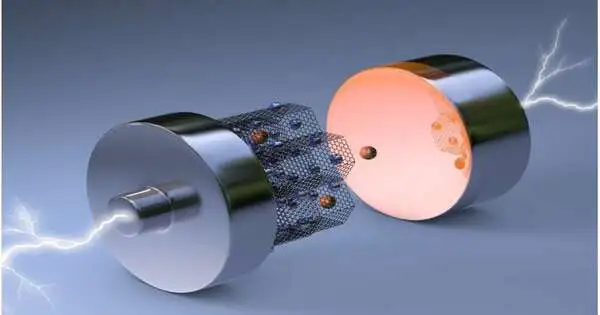

The scientists created another sort of anode for lithium-particle batteries that could release more prominent power and quicker charging. They did this by making thicker cathodes—the decidedly and adversely charged pieces of the battery that convey capacity to a gadget—utilizing magnets to make a novel arrangement that evades normal issues related to evaluating these basic parts.

As a result, a cathode with twice the range on a single charge for an electric vehicle is possible, compared to a battery using a current business terminal.

“Two-layered materials are usually accepted as a promising contender for high-rate energy capacity applications since they just need to be a few nanometers thick for fast charge transport,” said Guihua Yu, a teacher in UT Austin’s Walker Branch of Mechanical Design and Texas Materials Foundation. “In any case, for thick-anode configuration-based future high-energy batteries, the restacking of nanosheets as building blocks can cause huge bottlenecks in control transport, prompting trouble in accomplishing both high energy and quick charging.”

“Two-dimensional materials are often regarded as a good candidate for high-rate energy storage applications since they only need to be several nanometers thick for rapid charge transfer,”

Guihua Yu, a professor in UT Austin’s Walker Department of Mechanical Engineering and Texas Materials Institute.

The way in to the disclosure, distributed in the Procedures of the Public Foundation of Sciences, involves slim two-layered materials as the building blocks of the cathode, stacking them to make thickness and afterward utilizing an attractive field to control their directions. The examination group utilized monetarily accessible magnets during the manufacture cycle to organize the two-layered materials in an upward arrangement, creating a fast track for particles to go through the cathode.

Normally, thicker anodes force the particles to travel longer distances through the battery, which results in slower charging time. The normal even arrangement of the layers of material that make up the anode forces the particles to wind to and fro.

“Our cathode shows better electrochemical execution somewhat due to the high mechanical strength, high electrical conductivity, and work with lithium-particle transport thanks to the novel engineering we planned,” said Zhengyu Ju, an alumni understudy in Yu’s examination bunch who is driving this task.

As well as contrasting their cathode with a business terminal, they likewise created an evenly organized anode involving similar materials for trial control purposes. They had the option to re-energize the upward thick anode to half energy level quickly, compared to 2 hours and 30 minutes with the even cathode.

The analysts stressed that they are from the get-go in their work around here. They checked out only a single kind of battery cathode in this examination.

They want to sum up their system of inwardly coordinated cathode layers to apply it to various kinds of terminals utilizing different materials. This could assist the method in being more broadly embraced in the industry, so it could empower future quick-charging yet high-energy batteries that power electric vehicles.

More information: Zhengyu Ju et al, Vertically assembled nanosheet networks for high-density thick battery electrodes, Proceedings of the National Academy of Sciences (2022). DOI: 10.1073/pnas.2212777119

Journal information: Proceedings of the National Academy of Sciences