Plant-inferred materials, for example, like cellulose, frequently show thermally protecting properties. Another material produced using nanoscale cellulose filaments shows the opposite: high thermal conductivity. This makes it helpful in regions recently overwhelmed by engineered polymer materials. Materials like cellulose have natural advantages over polymers, so research on this could prompt greener mechanical applications where warm conductivity is required.

Cellulose is a vital underlying part of plant cell walls and is the justification for why trees can develop to such levels. Be that as it may, the mystery of its material strength really lies in its covering nanoscopic strands. As of late, numerous business items have utilized cellulose nanofiber (CNF) materials on the grounds that their solidarity and strength make them a decent trade for polymer-based materials, for example, plastics that can be impeding to the climate.

Be that as it may, presently and interestingly, an examination group led by Teacher Junichiro Shiomi from the College of Tokyo’s doctoral-level College of Design has researched beforehand the obscure warm properties of CNF, and their discoveries show these materials could be considerably more helpful still. Their examination shows up in nanoletters.

“When you see plant-derived materials like cellulose or woody biomass used in applications, it’s usually for mechanical or thermal insulating characteristics.”

Professor Junichiro Shiomi from the University of Tokyo’s

“In the event that you see plant-determined materials, for example, cellulose or woody biomass utilized in applications, regularly mechanical or thermally protecting properties are being utilized,” said Shiomi. “At the point when we investigated the warm properties of a yarn produced using CNF, nonetheless, we found that they show an alternate sort of warm way of behaving, warm conduction, and it’s extremely critical, multiple times higher than that of regular woody biomass or cellulose paper.”

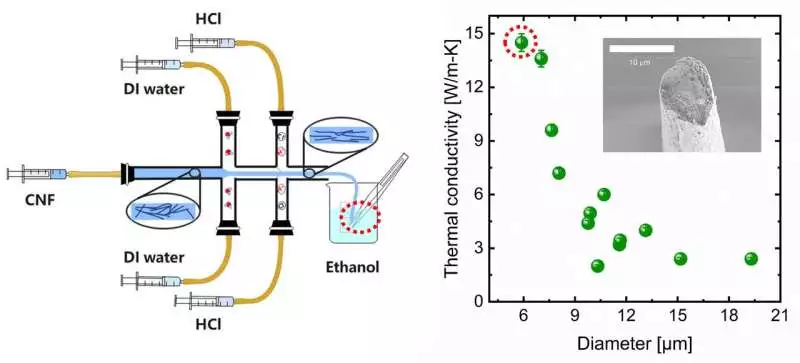

Stream centering and CNF The device to make thermally directed CNF utilizing muddled CNF, water, and hydrochloric acid (left) a diagram showing how the warm conductivity of the example changes with its width. (right). Credit: Nano Letters (2022). DOI: 10.1021/acs.nanolett.2c02057

The reason yarn produced using CNF can direct intensity so well is because of how it’s made. Cellulose strands in nature are extremely disrupted, yet a cycle called the stream centering strategy consolidates cellulose filaments, orienting them similarly, to make CNF. It’s this firmly bound and adjusted heap of pole-molded filaments that permits intensity to move along the pack, while in a more turbulent design it would dissipate heat all the more promptly.

“Our principal challenge was figuring out how to gauge the warm conductivity of such little actual examples with such incredible exactness,” said Shiomi.

“For this, we went to a strategy called T-type warm conductivity estimation.” It permitted us to quantify the warm conductivity of the pole-formed CNF yarn tests, which are just micrometers (a micrometer rising to one-thousandth of a millimeter) in breadth. However, the next stage for us is to perform precise warm tests on two-layered textilelike tests.

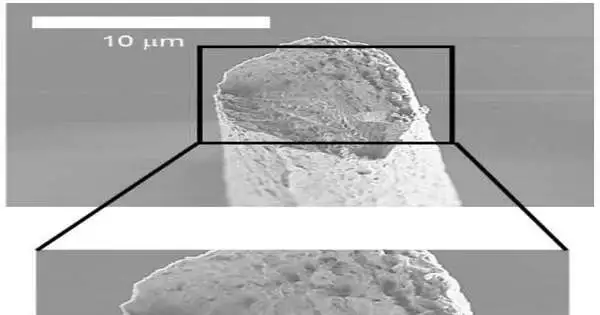

The mystery of CNF a craftsman’s translation of how regular cellulose strands are joined to frame the CNF yarn and an amplified segment showing the nanoscopic pole-molded fibers inside the yarn pack. Credit: Junichiro Shiomi

Shiomi and his group trust that their examination and future investigations into the utilization of CNF as a thermally conductive material could give designers an option in contrast to a few ecologically harmful polymers. In applications where intensity change is significant, for example, certain electronic or computational parts, it could enormously diminish the outcomes of disposed electronic hardware, or e-squander, on account of the biodegradable idea of CNF and other plant-based materials.

More information: Guantong Wang et al, Enhanced High Thermal Conductivity Cellulose Filaments via Hydrodynamic Focusing, Nano Letters (2022). DOI: 10.1021/acs.nanolett.2c02057

Journal information: Nano Letters