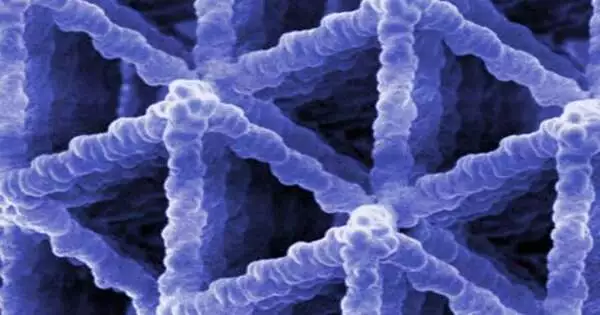

In spite of being a couple of iotas thick, MXene sneaks up suddenly. This class of single-layer, two-layered (2D) nanomaterials shows helpful properties like great thermal and electrical conductivity, heat opposition, and a high unambiguous surface region. These characteristics promise to change elite execution electronic gadgets and energy storage frameworks.

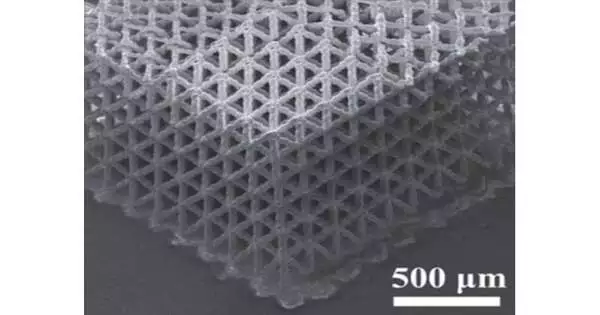

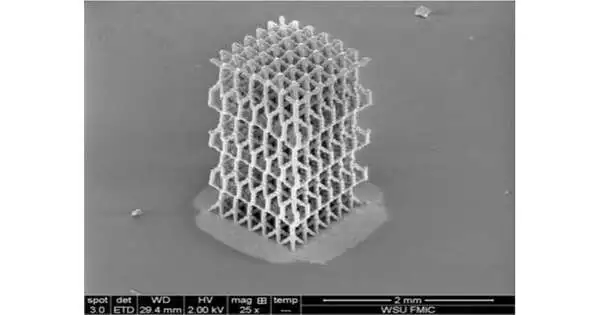

To upgrade MXene’s properties, analysts should have the option to organize 2D chips of it into three-layered (3D) setups. Such 3D models of MXene can build the energy stockpiling thickness of lithium-particle batteries and supercapacitors, as well as give execution upgrades to existing gadgets.

Sadly, there is an absence of solid assembling techniques accessible today for incorporating MXene into 3D setups. Rahul Panat, academic partner of mechanical design and partner head of the Manufacturing Futures Institute at Carnegie Mellon University, tries to change this.

“These three-dimensional designs are useful because they can ‘collect’ enough nanoscale materials for practical usage in electrical devices. I can greatly improve the performance of an electrode made of three-dimensional designs because the chemical and/or biochemical reactions have a larger surface area and 3D volume for operation.”

Rahul Panat, associate professor of mechanical engineering

The creation cycle will integrate Aerosol Jet 3D printing, a nanoscale added substance producing innovation. Using drop element standards, MXene will be dispersed in fluid and kept, layer by layer, in a slew of 3D designs to frame electrochemical and actual sensors.

“These three-layered models are helpful on the grounds that they can possibly ‘assemble’ enough nanoscale materials for viable use in electronic gadgets,” made sense of Panat.

“In the event that I make a cathode out of the three-layered models, I can decisively build its exhibition on the grounds that the compound as well as biochemical responses would have a higher surface region and 3D volume for activity.”

The examination group will test and survey the exhibition of these gadgets in view of their awareness, reproducibility, and repeatability of estimations.

One more part of the task looks forward to the up and coming age of the American labor force. To set up a partner of gifted laborers in the forefront of miniature and nanoelectronics advances, Panat’s group is selecting U.S. military trainees chasing after college degrees at Carnegie Mellon University, Duquesne University, and the University of Pittsburgh. Extra students incorporate a Ph.D. understudy and a postdoctoral individual from Panat’s examination lab.

The students will learn 3D printing and other high-level assembling strategies, in addition to material portrayal methods like electron microscopy, X-beam diffraction, and factual information examination.

Whenever they are prepared in the scope of 3D printing methods, the U.S. Flying Corps, Army and Navy recruits will actually want to fix mechanical parts and electronic circuits straightforwardly in the field. This will reduce reliance on rethinking and supply binds, which are vulnerable to serious disruption from global events.

Although the examination is key in nature, Panat guesses that it will begin to affect the industry in five to seven years. As technology advances, new high-performance electronic devices will emerge.