In the field of plastic upcycling, a research group led by Prof. Zeng Jie from the University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS) has made a significant advancement.

A novel dehydroaromatization and hydrogenolysis tandem strategy for converting high-density polyethylene (HDPE) plastics into valuable cyclic hydrocarbons without the use of solvents or hydrogen is presented in their study, which is titled “Solvent- and Hydrogen-Free Catalytic Conversion of High-Density Polyethylene Plastics.” Nature Nanotechnology published the findings.

Polyethylene, perhaps the most regularly utilized plastic, presents difficulties as far as normal corruption is concerned because of its steady synthetic design. Technologies for recycling polyethylene plastic waste not only reduce pollution but also help the economy.

Attracting motivation from two cycles in the petrol business, to be specific reactant changing of short-chain gas parts and hydrocracking of weighty oils, the examination group looked to regard squander HDPE plastics as a strong oil unrefined substance through harmless ecosystem synergist transformation, subsequently creating downstream oil-based compound items.

Enlivened by two cycles in the oil business, the exploration group zeroed in on the synergistic changing of short-affix fuel divisions to get higher-esteem cyclic hydrocarbons, which create hydrogen, and the hydrocracking of weighty oils to deliver short-chain hydrocarbons, which consume hydrogen.

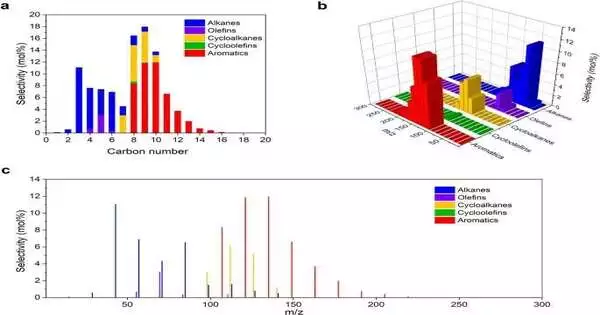

The research team came up with a “hydrogen-breathing” method for breaking down high-density polyethylene (HDPE) plastics based on these processes. They fostered a sub-atomic sifter-stacked metallic ruthenium impetus (Ru/HZSM-5) that works with the dehydrogenation of the plastic into cyclic hydrocarbons to “inhale out” hydrogen simultaneously. The released hydrogen is simultaneously “breathed in” by the plastic, which cracks and becomes short-chain hydrocarbons.

The examination group then, at that point, investigated the upcycling response pathways of high-thickness polyethylene plastics. They directed synergist probes at the reuse of HDPE plastics with various sub-atomic strainer loadings of ruthenium metal and analyzed the impact of the sub-atomic sifter pores on the response.

The outcomes show that the HZSM-5 sub-atomic strainer has a moderate pore size, which not only evades the development of thick, sweet-smelling cyclic hydrocarbons and carbon stores but additionally guarantees the smooth desorption of cyclic hydrocarbons, consequently ensuring the coherence and security of the synergist response. Ru/HZSM-5 impetuses have excellent cyclic soundness and are likewise reasonable for various sorts of polyethylene plastics.

This study is a significant advance in plastic recycling and holds great promise for our society’s sustainable growth. By giving an inventive answer for the change of HDPE plastics into important cyclic hydrocarbons, this study adds to the continuous endeavors to address plastic waste and advance a more economical future.

More information: Junjie Du et al, Efficient solvent- and hydrogen-free upcycling of high-density polyethylene into separable cyclic hydrocarbons, Nature Nanotechnology (2023). DOI: 10.1038/s41565-023-01429-9