Chitin hydrogel is perceived as a promising material for various biomedical applications. Its biocompatibility and biodegradability make it helpful in tissue fixation, counterfeit organs, and wound recuperation. However, researchers keep on confronting difficulties in creating chitin hydrogel. A group of scientists has fostered a green, productive, and versatile planning strategy for chitin hydrogels.

The team’s work paves the way for chitin hydrogels’ practical applications as superior biomedical materials and provides a rational method for their production.

Their discoveries are distributed in the journal Nano Exploration.

Chitin, the second most plentiful regular polymer, is a substance that comes from the exoskeletons of crabs, prawns, and bugs. Chitin is sustainable, degradable, biocompatible, and requires minimal expense. These characteristics make it an incredible contender for different biomedical purposes.

“Chitin hydrogel, which resembles extracellular matrix in many ways, is an ideal material for tissue engineering and regenerative medicine. However, dissolving chitin in aqueous solutions to form hydrogel polymers is difficult. As a result, developing a logical fabrication method is critical.”

Li-Bo Mao, a professor at the University of Science and Technology of China.

“Chitin hydrogel, which imparts numerous similitudes to the extracellular network, is an ideal material for tissue design and regenerative medication. To make hydrogels, however, it is difficult to dissolve chitin in aqueous solutions. In this manner, it is of extraordinary importance to foster a reasonable creation system,” said Li-Bo Mao, a teacher at the College of Science and Innovation of China.

The chitin hydrogel needs to be biologically safe, have the right mechanical strength, and be chemically stable for it to be useful in biomedical applications. It should oppose biofouling, which could prompt a fiery reaction or resistant dismissal in the human body. For business use, the chitin hydrogel should likewise be minimally expensive and versatile.

The difficulties in manufacturing solid chitin hydrogel emerge in view of the insolubility of chitin in numerous solvents and the diminished chain length of chitin recovered from arrangements. Biopolymer hydrogels are commonly prepared with a two-step process: the disintegration of the biopolymer and the resulting gelation.

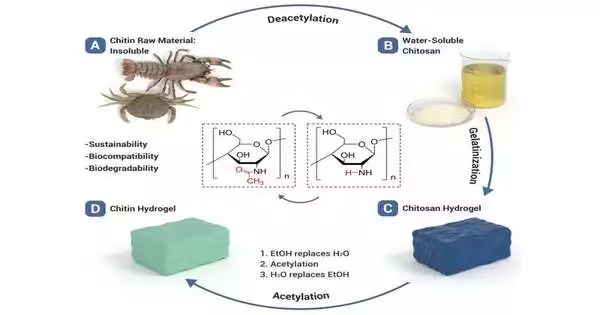

Nonetheless, chitin isn’t dissolvable in water or other normal solvents in light of the various inter- and intra-atomic hydrogen connections between the polymer chains. The group handled this test by manufacturing chitin hydrogel with a biomimetic structure through the synthetic change of chitosan, a water-solvent deacetylated subsidiary of chitin.

In the presence of acids, chitosan dissolves readily in water. These chitosan hydrogels can be invested with various microstructures. In any case, they are not precisely or artificially steady. Endeavors to further develop them by utilizing crosslinking specialists have raised biosafety concerns.

The group was effective in creating a synthetically stable and antifouling chitin hydrogel by means of a compound response called acetylation. Through the acetylation cycle, the chitin hydrogel the group acquired has remarkable protection from enlarging, corruption, outrageous temperature and pH conditions, and natural solvents.

In addition, the group discovered that chitin hydrogels with various biomimetic structures could be made by combining the chitosan precursor with ice crystals. These designs can be either nacre-like or wood-like, contingent upon the freezing technique utilized with the chitosan precursor.

The chitin hydrogel created by the group has phenomenal mechanical properties while holding a high water content. It also resists the adhesion of proteins, bacteria, blood, and cells, demonstrating excellent antifouling performance.

“The hydrogel materials that we obtained are mechanically strong and robust, in addition to the numerous advantages that are characteristic of chitin. What’s more, the hydrogels can be handled into various shapes and designs. These guarantee the pragmatic uses of the chitin hydrogels,” said Mao.

Looking forward, the group’s subsequent stage is to additionally work on the mechanical properties of chitin hydrogels and investigate their biomedical applications by means of in vivo experiments. “We expect different chitin-based hydrogel materials can be manufactured through this procedure and utilized for various clinical applications, like ligament substitution, bone substitution, wound dressing, and, surprisingly, counterfeit organs,” said Mao.

More information: Rui-Rui Liu et al, Biomimetic chitin hydrogel via chemical transformation, Nano Research (2023). DOI: 10.1007/s12274-023-5886-5