Ultrathin films (thickness 100 nm) are a significant class of modern materials. Constant advancements in deposition techniques, as well as micro and nanoscale patterning, have significantly contributed to the development of thin film functionality. Ultrathin films, particularly in materials technology, play an important role in products such as solar cells, sensors, and displays. It is obvious that the current research prospects are extensive.

Researchers have created a new ultra-thin film that can generate detailed 3D images that can be viewed under normal lighting without the use of any special reading devices. The images appear to float on top of the film and are visible from every angle. The new imaging film employs light-field imaging technology, which captures the direction and intensity of all light rays within a scene to create a 3D image. The new glass-free approach could be used as a visual security feature or incorporated into virtual or augmented reality devices with further development.

“Our ultra-thin, integrated reflective imaging film creates an image that can be viewed from a wide range of angles and appears to have physical depth,” said research team leader Su Shen from Soochow University in China. “It can be easily laminated to any surface as a tag or sticker or integrated into a transparent substrate, making it suitable for use as a security feature on banknotes or identity cards.”

Our ultra-thin, integrated reflective imaging film creates an image that can be viewed from a wide range of angles and appears to have physical depth. It can be easily laminated to any surface as a tag or sticker or integrated into a transparent substrate, making it suitable for use as a security feature on banknotes or identity cards.

Su Shen

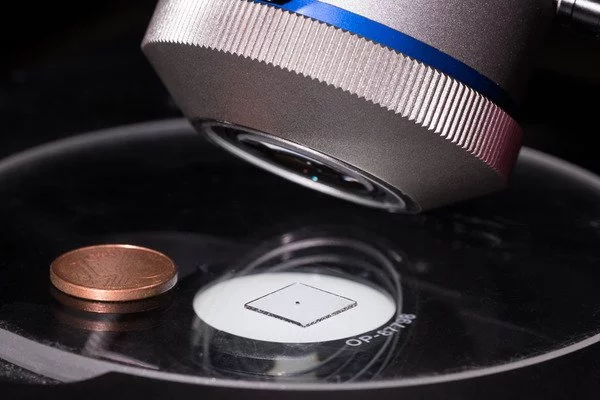

The researchers describe their new imaging film in Optics Letters, an Optica Publishing Group journal. The film is about twice as thick as household plastic wrap and is only 25 microns thick. It employs light-field imaging, which captures the direction and intensity of all rays of light within a scene to create a 3D image.

“Achieving glass-free 3D imaging with a large field of view, smooth parallax, and a wide, focusable depth range under natural viewing conditions is one of the most exciting challenges in optics,” said Shen. “Our approach provides an innovative way to achieve vivid 3D images that cause no viewing discomfort or fatigue, are easy to see with the naked eye, and are aesthetically pleasing.”

High-density recording

Various technical schemes have been investigated in order to create the ideal 3D viewing experience, but they all have drawbacks such as a limited viewing angle or low light efficiency. To address these shortcomings, the researchers created a reflective light-field imaging film and a new algorithm that allows both position and angular information for the light field to be recorded with high density.

The researchers also developed a low-cost self-releasing nanoimprinting lithography approach that can achieve the precision required for high optical performance. On one side, the film is patterned with an array of reflective focusing elements that function similarly to miniature cameras, while the other side contains a micropattern array that encodes the image to be displayed.

“The powerful microfabrication approach we used allowed us to make an extremely compact reflective focusing that measured only tens of microns,” Shen explained. “This allows light radiance to be densely collected, resulting in a realistic 3D effect.”

A realistic 3D image

The researchers used their new film to create a 3D image of a cubic die that could be clearly seen from almost any angle. Under natural lighting conditions, the resulting image measures 8 x 8 millimeters and has an image depth ranging from 0.1 to 8.0 millimeters. They have also designed and manufactured an imaging film with a floating logo that can be used as a decorative element, such as on the back of a mobile phone.

According to the researchers, their algorithm and nanopatterning technique could be extended to other applications by creating the nanopatterns on a transparent display screen rather than a film, for example. They are also working to commercialize the fabrication process by developing a double-sided nanoimprinting machine that would make it easier to achieve the precise alignment required between the micropatterns on each side of the film.