New materials and ideas are frequently inspired by nature by engineers. The attachment of bone and tendon in the shoulder joint was discovered by a multi-institutional collaboration of researchers and engineers, revealing previously unknown engineering techniques for joining diverse materials. The revelation also provides new insight into the operation of the rotator cuff and the reasons for the frequent failure of rotator cuff repairs.

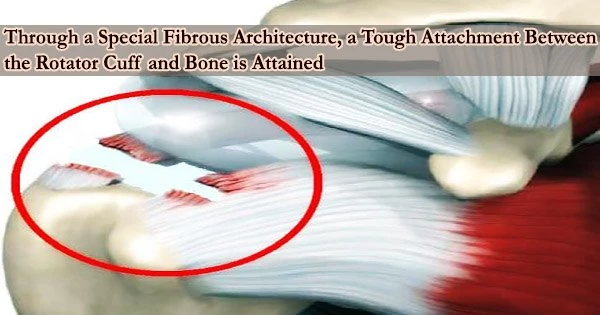

Guy Genin, the Harold and Kathleen Faught Professor of Mechanical Engineering in the McKelvey School of Engineering at Washington University in St. Louis, and Stavros Thomopoulos, the Robert E. Carroll and Jane Chace Carroll Professor of Orthopaedic Surgery at Columbia University, led a team that discovered a previously unknown fibrous architecture between the rotator cuff tendons and their bony attachments in the shoulder. Results of the work were published in Science Advances Nov. 26.

The most frequent tendon injuries in adults, rotator cuff tears happen when tendons pull away from or break close to the bone. Over 60% of people over the age of 80 and 30% of people over the age of 60 both experience tears.

Depending on age and other circumstances, surgery to heal the tears has a significant failure rate, which can range from 30% to 90%. For many years, Genin, Thomopoulos, and their teams have been researching the mechanobiology of these tissues.

The scientists used a cutting-edge micro computed tomography (microCT) method to get a better look at the enthesis, or the transitional material where each of the four rotator cuff tendons joins to the bone.

This research gave us a whole new look at this frequently-injured region and presented a new thinking of how to attach these two different materials. This is not just important for surgeries, but for all kinds of engineering failures that occur when you connect a material to something with a different architecture. By merging the architectural paradigms across the materials and enabling the distributed failure of the elements that come together, you can dramatically increase toughness.

Professor Guy Genin

The scans showed a hidden location where tendon fibers directly penetrated into bone across roughly 30% of the well-known attachment footprint in the supraspinatus tendon enthesis of mouse shoulders.

They discovered through biomechanical analysis and numerical simulations that the composition, structure, and location of the enthesis which mediates the interaction between the architecture of the fibrous soft tissues and the architecture of the bone are what give the healthy rotator cuff its toughness. It was the first time that scientists had the ability to concurrently observe both the soft and hard components in the rotator cuff.

“When lead author Mikhail Golman first showed us these images, we realized that much of the old picture of how tendon and bone interact had to be redrawn,” Genin said. “The fiber system there seems like fibers in a rope, and we can understand much about where the toughness comes from by understanding how these fibers break sequentially when they are next to the bone. It’s a new way of thinking about how to attach different materials.”

After the team found the hidden site, there were further discoveries as they progressed.

“Every experiment we did revealed fascinating new features of the attachment system,” Thomopoulos said. “We quickly realized that fundamental aspects of this problem needed to be rethought from scratch. Our goal was to understand where the healthy rotator cuff gets its toughness and strength and under what conditions it ruptures. We found that the toughness of the rotator cuff varies as a function of shoulder position, helping to explain differences in the injury patterns seen in patients.”

The research team discovered that the fibers’ role in constructing the connection between bone and tissue gives the rotator cuff its durability. Toughness refers to how much energy is required to break a structure, while strength refers to how hard one has to pull to break it, Genin said.

“We found that there’s actually a tradeoff between strength and toughness with these fiber systems,” Genin said. “If you reduce the overall strength by allowing some of the fibers to break, you can actually make the structure tougher because the amount of energy absorbed increases.”

Genin said their results showed that replicating the fiber structure is essential for successful and pain-free healing after rotator cuff repair.

“This research gave us a whole new look at this frequently-injured region and presented a new thinking of how to attach these two different materials,” Genin said.

“This is not just important for surgeries, but for all kinds of engineering failures that occur when you connect a material to something with a different architecture. By merging the architectural paradigms across the materials and enabling the distributed failure of the elements that come together, you can dramatically increase toughness.”