Another review proposes that unpleasant surfaces enlivened by the microbe-killing spikes on bug wings might be more compelling at fighting medication-safe superbugs, including growth, than recently comprehended.

The rising pace of medication contamination has wellbeing specialists universally concerned.

To keep away from contamination around inserts—like titanium hips or dental prostheses—specialists utilize a scope of antimicrobial coatings, synthetic compounds, and anti-infection agents; however, these neglect to stop anti-microbial safe strains and could increase obstruction.

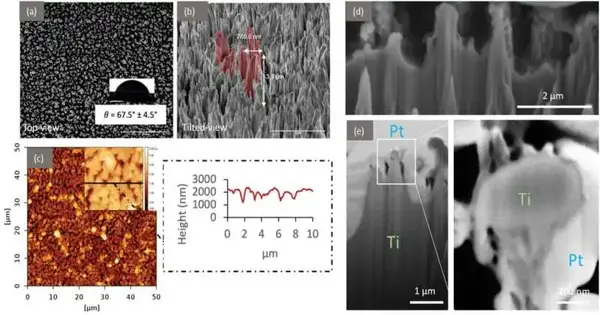

To address these difficulties, RMIT College researchers have planned an example of microscale spikes that can be scratched onto titanium inserts or different surfaces to give viable results without drug insurance from the two microorganisms and their growth.

“Even after seven days, the injured Candida cells were subjected to extensive metabolic stress, preventing the process by which they reproduce to form a lethal fungal biofilm. They could not be revived in a non-stress environment and eventually died as a result of apoptosis, or programmed cell death.”

Linklater, from RMIT’s School of Science.

The group’s review distributed in Cutting Edge Materials Connection Points tested the viability of the changed titanium surface in killing multi-drug-safe Candida, a possibly destructive organism liable for one of every 10 clinic-acquired clinical gadget diseases.

The extraordinarily planned spikes, every one of a level like that of a microorganism’s cell, obliterated about a portion of the cells not long after contact.

Altogether, the other half not quickly annihilated were rendered unviable from the wounds maintained, incapable of repeating or causing disease.

Lead postdoctoral analyst, Dr. Denver Linklater, said metabolic examination of protein action uncovered both the Candida albicans and multi-drug-safe Candida auris growth cells sitting harmed on a superficial level were comparable to dead.

“The Candida cells that were harmed went through broad metabolic pressure, forestalling the cycle where they duplicate to make a lethal parasitic biofilm, even after seven days,” said Linklater, from RMIT’s School of Science. “They couldn’t be resuscitated in a non-stress climate and ultimately shut down in a cycle known as apoptosis, or modified cell death.”

The surface’s adequacy against normal pathogenic microorganisms, including brilliant staph, was shown in a prior study distributed in Materialia.

Bunch pioneer and recognized teacher Elena Ivanova said the most recent discoveries shed light on the plan of antifungal surfaces to forestall biofilm arrangement by risky, multi-drug-safe yeasts.

“The way that cells kicked the bucket after starting contact with the surface—some by being cracked and others by customized cell passing before long—recommends that protection from these surfaces won’t be created,” she said. “This is a critical finding and furthermore recommends that the manner in which we measure the viability of antimicrobial surfaces might be reconsidered.”

Progress has been made over the course of the last 10 years in planning surfaces that kill superbugs on contact. Notwithstanding, tracking down the right kinds of surface examples to kill 100 percent of microorganisms so some don’t get by and become safe is a continuous test.

“This most recent review recommends that it may not be altogether vital for all surfaces to dispense with all microorganisms promptly upon contact in the event that we can show that the surfaces are causing modified cell passing in the enduring cells, meaning they kick the bucket in any case,” she said.

RMIT’s Multifunctional Mechano-biocidal Materials Exploration Gathering has driven the world for nearly 10 years in the advancement of antimicrobial surfaces roused by the nanopillars covering dragonfly and cicada wings. Ivanova herself was among the first to see how when microbes choose a bug wing, the example of nanopillars pulls the layers apart, lethally cracking the layers.

“It resembles extending a plastic glove,” Ivanova said. “As it gradually extends, the most fragile point in the plastic will become more slender and, in the end, tear.”

Her group has gone through the previous ten years repeating these bugs’ nanopillars in nanopatterns of their own, with this most recent development accomplished utilizing a method called plasma carving to make the antibacterial and antifungal examples in titanium.

Ivanova said the somewhat straightforward carving method could be streamlined and applied to a large number of materials and applications.

“This new surface adjustment method could have possible applications in clinical gadgets yet could likewise be effortlessly changed for dental applications or for different materials like treated steel seats utilized in food creation and agribusiness,” she said.

Concentrate on lead creator and joint Ph.D. competitor with RMIT and the Curve Exploration Center point for Australian Steel Assembling, Phuc Le, said working intimately with industry accomplice BlueScope Steel helped center endeavors to pragmatic answers for industry.

“Working together with modern accomplices has been a groundbreaking part of my Ph.D. venture,” he said. “Their direct bits of knowledge as makers have given lucidity on the difficulties their items face and opened entryways for me to research and devise reasonable arrangements. While our examinations are in the starter organizes, the possibilities for item streamlining are promising.”

More information: Phuc H. Le et al, Apoptosis of Multi‐Drug Resistant Candida Species on Microstructured Titanium Surfaces, Advanced Materials Interfaces (2023). DOI: 10.1002/admi.202300314